Indirect constant temperature heating device

A constant temperature heating and indirect technology, applied in indirect heat exchangers, energy-saving heating/cooling, lighting and heating equipment, etc., can solve problems affecting beverage function and taste, poor use effect, and material activity damage, etc., to meet the requirements of beverages Production process requirements, reasonable structure, and the effect of solving the protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

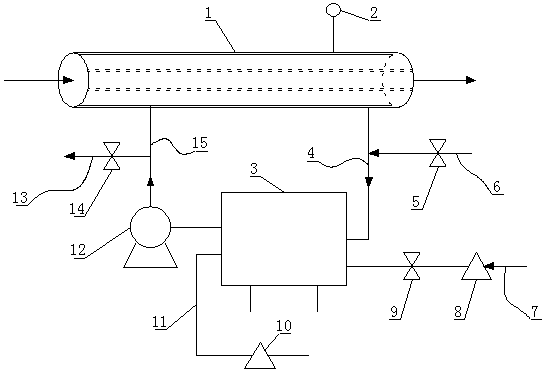

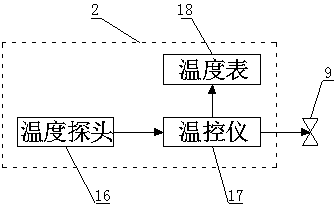

[0019] like Figure 1-2 As shown, an indirect constant temperature heating device includes a plate heat exchanger 3 and a tube heat exchanger 1, the right side of the plate heat exchanger 3 is connected with a steam pipe 7, and the steam pipe 7 is set There is a steam pressure reducing valve 8 and a steam regulating valve 9, and the right side of the plate heat exchanger 3 is also connected to the right circulation pipe 4, and the right circulation pipe 4 is connected to the tube heat exchanger 1, so The said right circulation pipe 4 is connected with a water supply pipe 6, and said water supply pipe 6 is provided with a water inlet valve 5, and the left side of said plate heat exchanger 3 is connected with a left circulation pipe 15, and said left The side circulation pipe 15 is connected to the tubular heat exchanger 1, the circulation water pump 12 is arranged on the left circulation pipe 15, the drain pipe 13 is connected to the left circulation pipe 15, and the drain pipe...

Embodiment 2

[0022] like Figure 1-2 As shown, an indirect constant temperature heating device includes a plate heat exchanger 3 and a tube heat exchanger 1, the right side of the plate heat exchanger 3 is connected with a steam pipe 7, and the steam pipe 7 is set There is a steam pressure reducing valve 8 and a steam regulating valve 9, and the right side of the plate heat exchanger 3 is also connected to the right circulation pipe 4, and the right circulation pipe 4 is connected to the tube heat exchanger 1, so The said right circulation pipe 4 is connected with a water supply pipe 6, and said water supply pipe 6 is provided with a water inlet valve 5, and the left side of said plate heat exchanger 3 is connected with a left circulation pipe 15, and said left The side circulation pipe 15 is connected to the tubular heat exchanger 1, the circulation water pump 12 is arranged on the left circulation pipe 15, the drain pipe 13 is connected to the left circulation pipe 15, and the drain pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com