Full-automatic sample injector capable of exchanging sample positions, and element analyzer

An elemental analyzer, fully automatic technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems of labor-intensive, cumbersome operation, limited time for continuous automatic operation, etc., to achieve the effect of meeting timeliness and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

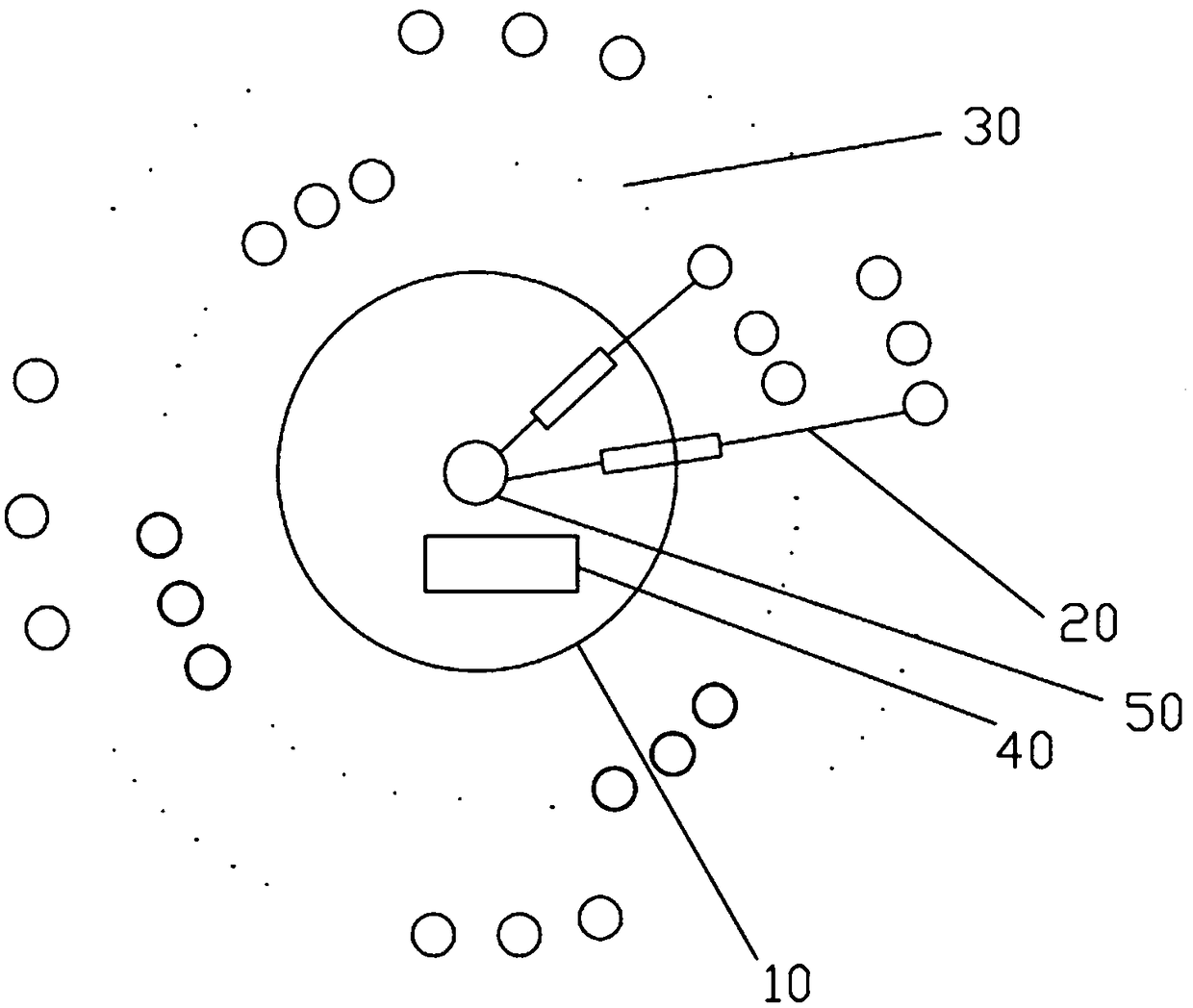

[0035] In this embodiment, a fully automatic sample injector with exchangeable sample positions is provided. Such as figure 1 As shown, the automatic sample injector with interchangeable sample positions of the present invention includes: a disc body 10 , N holes 70 , N telescopic rods 20 , a sample running track 30 , an electromagnetic power system 40 and a rotating shaft 50 .

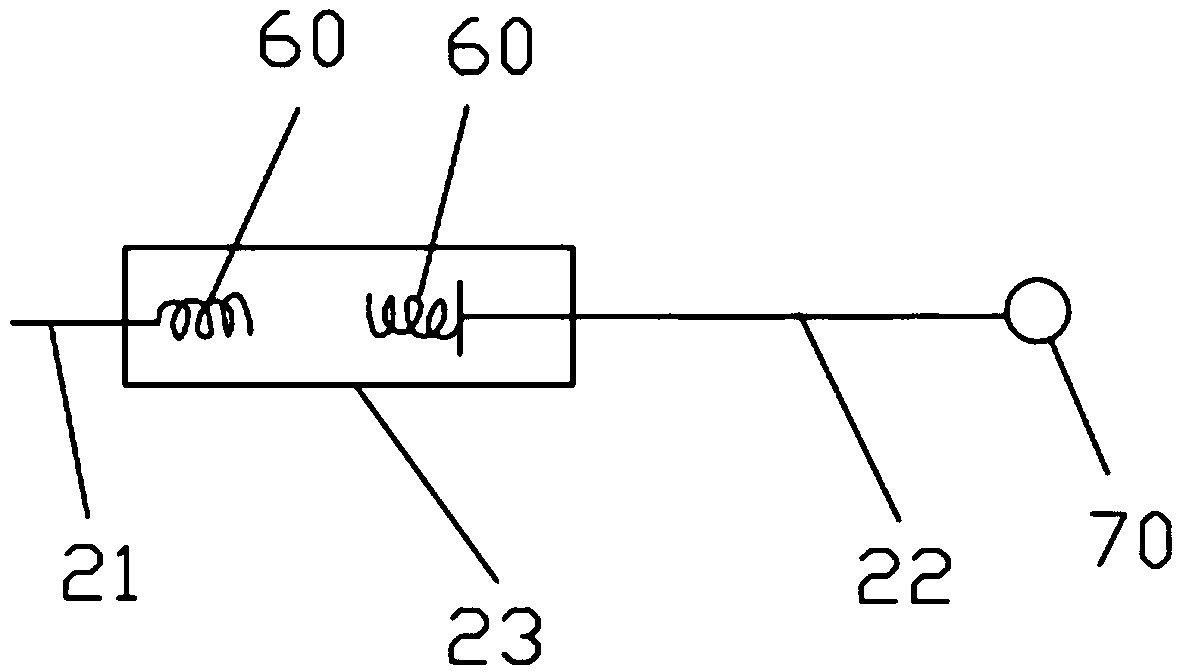

[0036] N holes 70 are arranged to form two sample loops, which are divided into the first ring and the second loop, and all the holes are located on the same plane, for example, each sample loop has 80 holes, figure 1 The black dots in the figure represent unillustrated holes. Samples are installed in the holes 70. When the holes 70 rotate in the sample running track 30, the samples in the holes 70 are sent to the elemental analyzer for analysis. Elemental analysis. One end of the telescopic rod 20 is connected to the rotating shaft 50, and the other end is fixedly connected to a hole 70. When the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com