Method for measuring total iron content in iron concentrate powder in iron and steel enterprises

A technology for iron powder and iron content, which is used in measuring devices, instruments, scientific instruments, etc., can solve problems such as point dispersion and poor calibration curve effect, and achieve the effects of satisfying accuracy, reducing smelting costs, and reducing safety risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] A method for iron and steel enterprises to measure total iron content in fine iron powder,

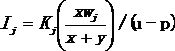

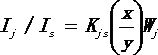

[0009] 1. Selection experiment of internal standard elements: the present invention uses data such as the intensity of the internal standard of the sample and the ratio of the analysis line or the intensity ratio of the coherent scattering line between the analysis line and the target line in the selection of the internal standard elements to calculate the element concentration, function In order to obtain the effect of compensating the effect of absorption enhancement and instrument drift. The principle is as follows: a certain amount of known substance S (internal standard substance Co 2 o 3 ), measure the diffraction intensity of the known substance and the measured phase J phase (the content of total iron in the iron concentrate powder), and plot the intensity ratio to obtain the change value of the average mass absorption coefficient of the sample. Add y gram internal sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com