Photovoltaic cell module and preparation methods thereof

A photovoltaic cell and module technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of large spacing, space waste, and inability to effectively use the space between photovoltaic cells, so as to increase the light-receiving area and avoid space waste , The effect of improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

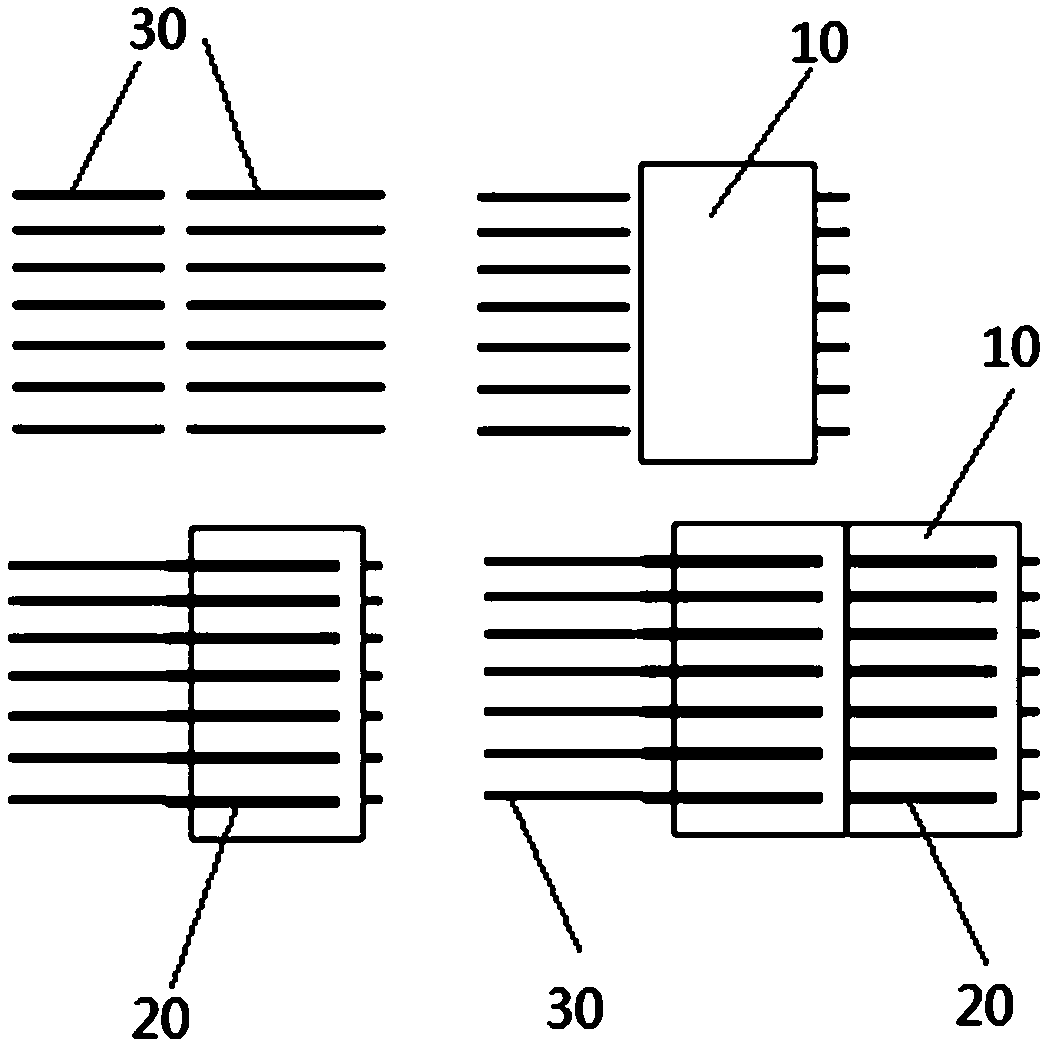

[0048] According to another aspect of the present invention, the present invention further provides a method for preparing a first photovoltaic cell module. The preparation method of the photovoltaic cell module comprises the following steps:

[0049] A. Arrange multiple sets of front interconnection conductive strips 30 at equal intervals on the platform;

[0050] B. Place a photovoltaic cell unit 10 on each group of front interconnected conductive strips 30 and place a photovoltaic cell unit 10 on each photovoltaic cell unit 10 in turn in the order of a photovoltaic cell unit 10 and a group of reverse interconnected conductive strips 20 A set of back-side interconnected conductive strips 20, so that the front electrodes of each photovoltaic cell unit 10 are aligned one by one and cover each front-side interconnected conductive strip 30 of the same group, and one end of the front-side interconnected conductive strip 30 does not exceed the photovoltaic cell The edge of the sh...

Embodiment 1

[0077] Example 1: Single-polycrystalline single-sided or double-sided battery + triangular ribbon + horizontal version

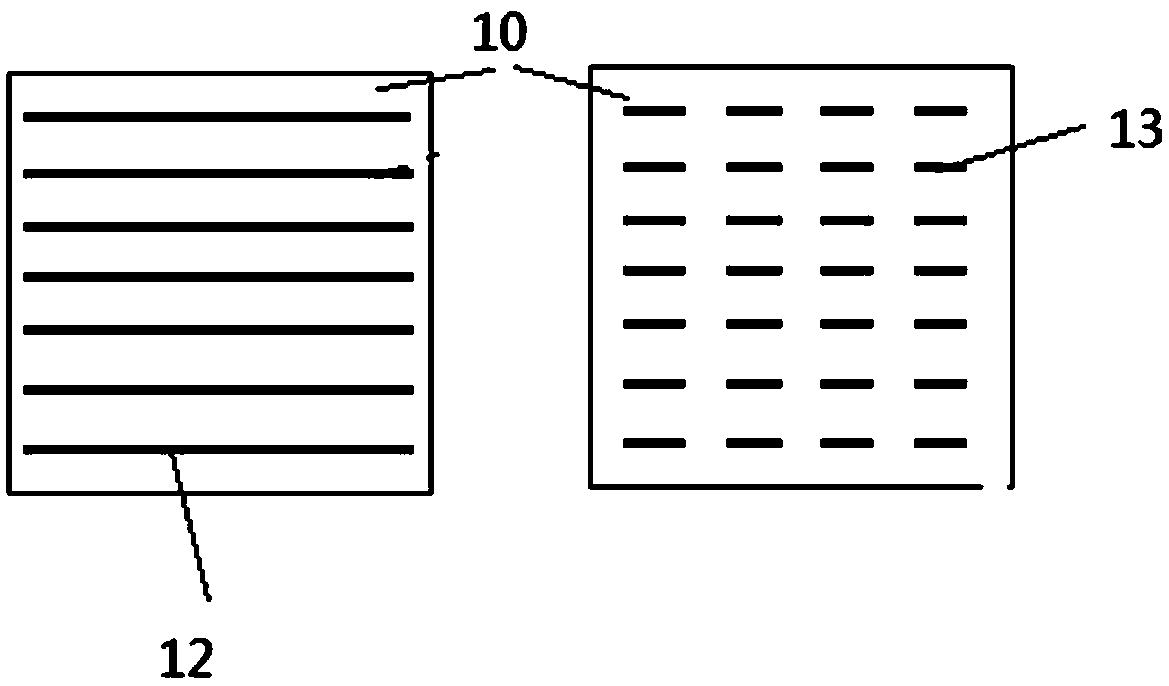

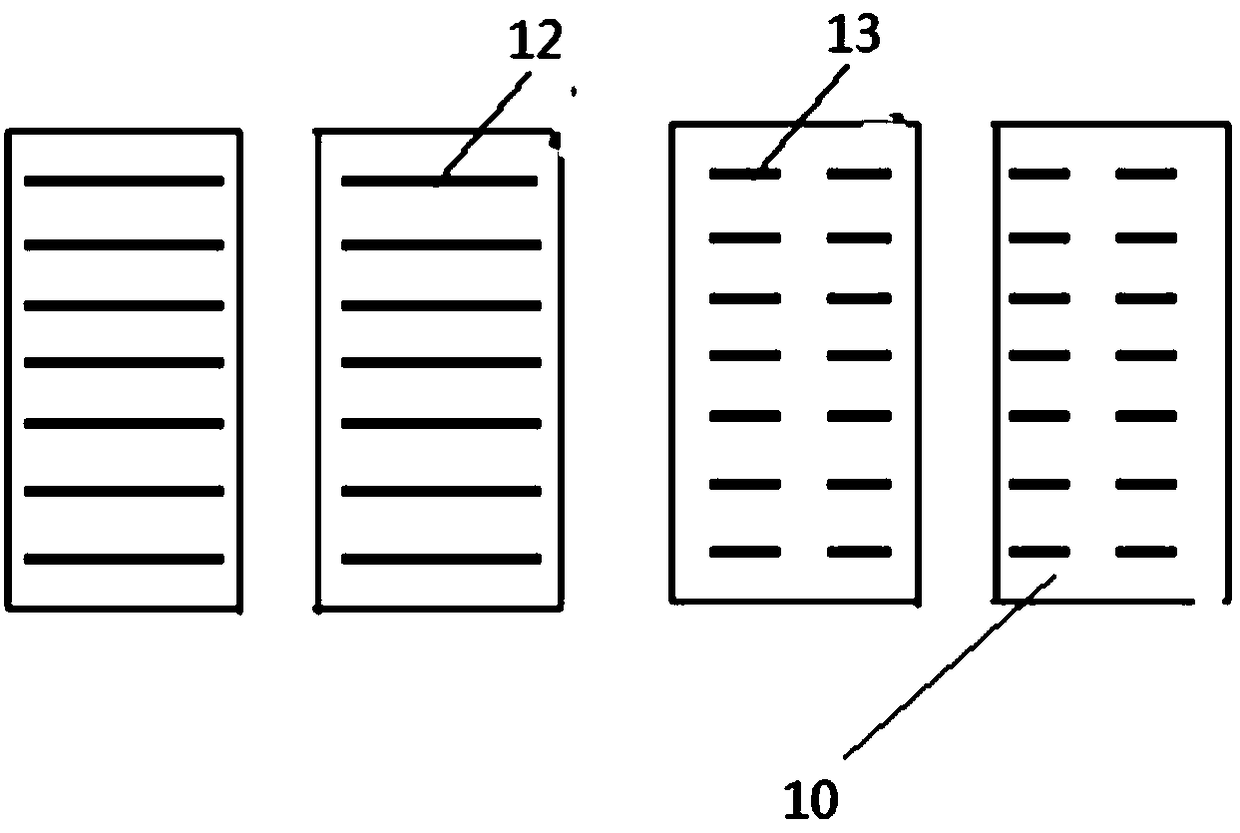

[0078] 1. Preparation of the photovoltaic cell unit 10: a single-crystal or polycrystalline P-type single-sided or double-sided power generation cell is cut in half from a standard-sized photovoltaic cell of 156.75*156.75 in half. There are 7 front electrodes with a width of 0.3mm, the distance between the front electrodes is 22.1mm, and the back electrodes are divided into two sections.

[0079]2. Preparation of the front interconnection conductive strip 30 and the reverse interconnection conductive strip 20: use an ultra-thin tinned copper flat strip of 0.08mm*2mm as the reverse interconnection conductive strip 20, and the thickness of the tinned layer on one side of the tinned copper flat strip is 0.015mm. A tinned triangular solder strip is used as the front interconnection conductive strip, the side length of the cross section is 0.5mm, and the thickne...

Embodiment 2

[0083] Example 2: Single-polycrystalline single-sided or double-sided battery + triangular ribbon + vertical version

[0084] 1. Preparation of the photovoltaic cell unit 10: the monocrystalline or polycrystalline P-type single-sided or double-sided power generation cell is cut in half from a standard-sized photovoltaic cell of 156.75mm*156.75mm in half. There are 7 front electrodes with a width of 0.3mm, the distance between the front electrodes is 22.1mm, and the back electrodes are divided into two sections.

[0085] 2. Preparation of the front interconnection conductive strip 30 and the reverse interconnection conductive strip 20: use an ultra-thin tinned copper flat strip of 0.08mm*2mm as the reverse interconnection conductive strip 20, and the thickness of the tinned layer on one side of the tinned copper flat strip is 0.015mm. A tinned triangular solder strip is used as the front interconnection conductive strip, the side length of the cross section is 0.5mm, and the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com