Laser double-sided machining alignment technology

A double-sided processing and laser technology, which is applied to the formation of electrical connections of printed components, electrical components, printed circuit manufacturing, etc., can solve problems such as high temperature, difficult blind hole alignment, and affect the quality of blind hole processing, etc., to achieve convenience View and monitor the effects of improving process quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

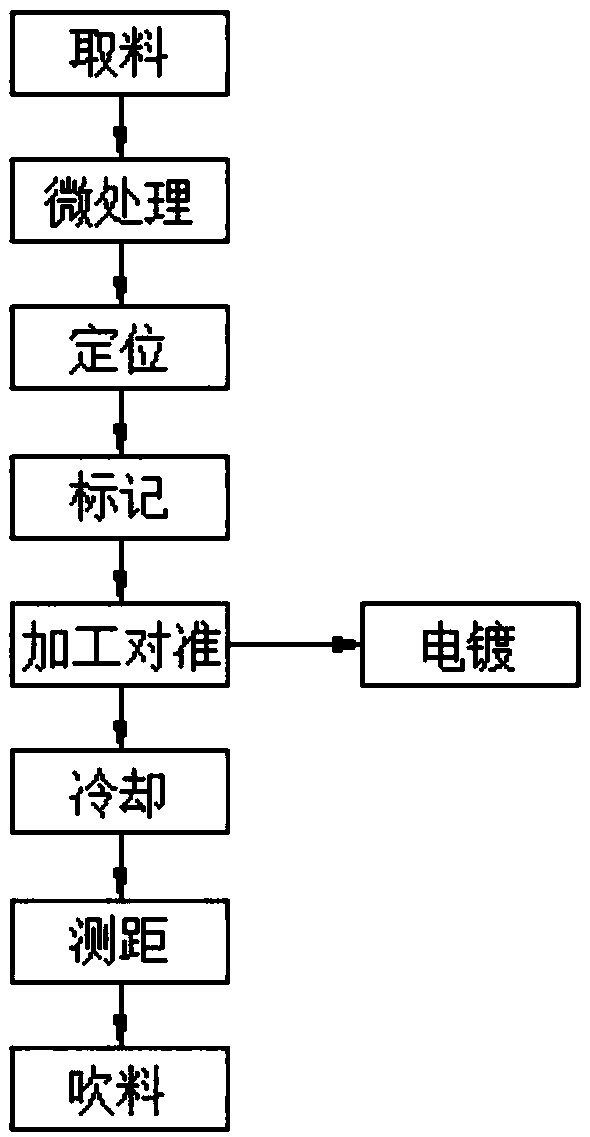

[0023] see figure 1 , in an embodiment of the present invention, a laser double-sided processing alignment process includes the following steps:

[0024] 1) Reclaiming: Manually place the PCB to be processed on the processing platform;

[0025] 2) Micro-processing: Wipe the edge of the PCB board clockwise with a dry paper towel, and blow off the dust on the edge of the PCB board with a blower, where the rated voltage of the blower is 220V, and the air volume is 2.2m 3 / min, the rated power of the blower is 600W, and the diameter of the air outlet of the blower is 3cm;

[0026] 3) Positioning: G-shaped clamps are used to clamp the edge of the PCB board, wherein the G-shaped clamps include a clamp body, a T-shaped screw rod, a threaded screw welded under the T-shaped screw rod, and a threaded wire The movable clamping head under the rod, wherein the clamping length of the G-shaped clamp is 25mm, and the size of the G-shaped clamp is 1 inch, the clamping depth of the G-shaped c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com