Corn threshing device for agricultural processing

A corn threshing and agricultural processing technology, applied in the agricultural field, can solve problems such as no separation of corn and corn cobs, poor threshing effect, incomplete threshing of corn kernels, etc., to achieve simple and compact overall structure, thorough threshing, and good threshing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

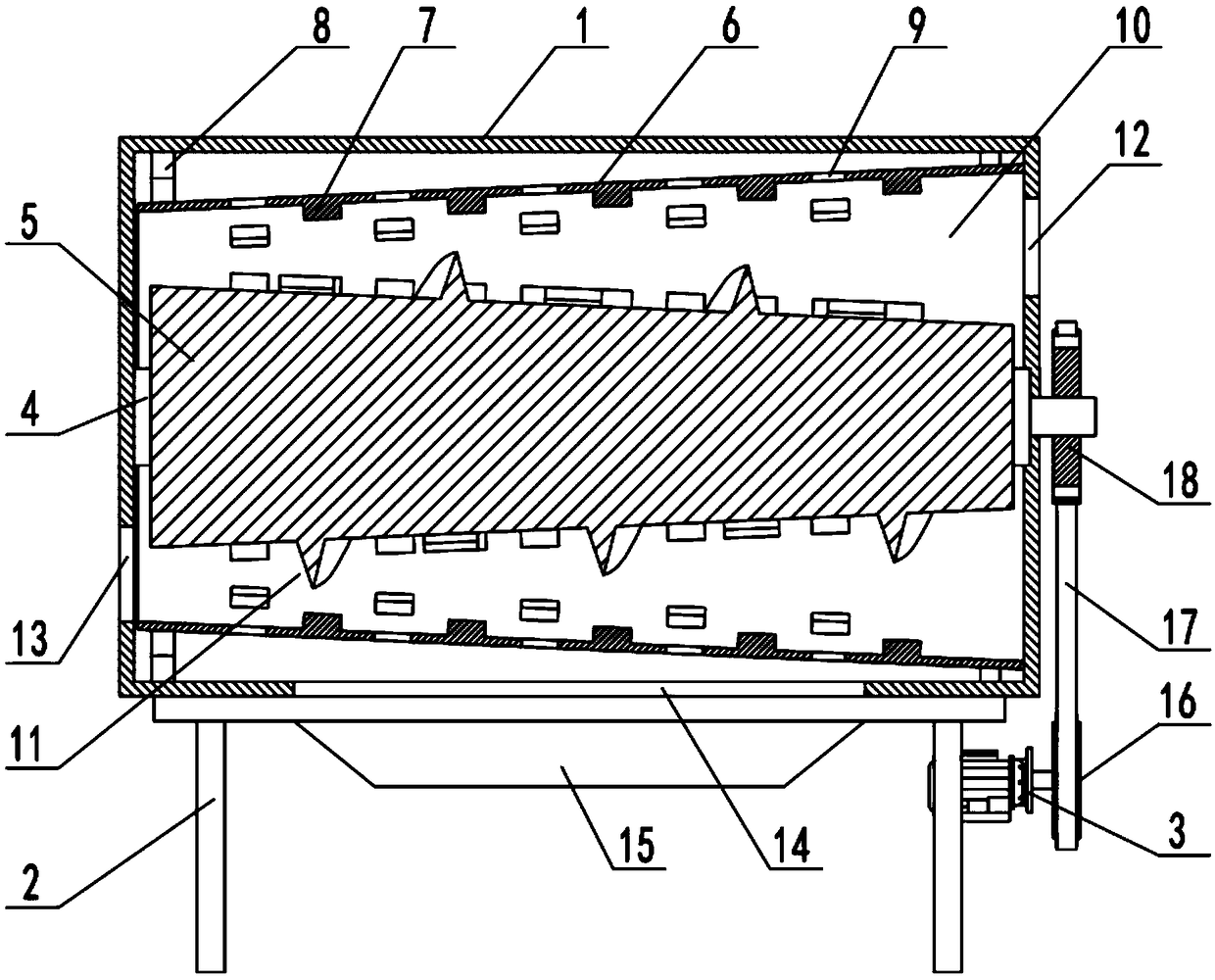

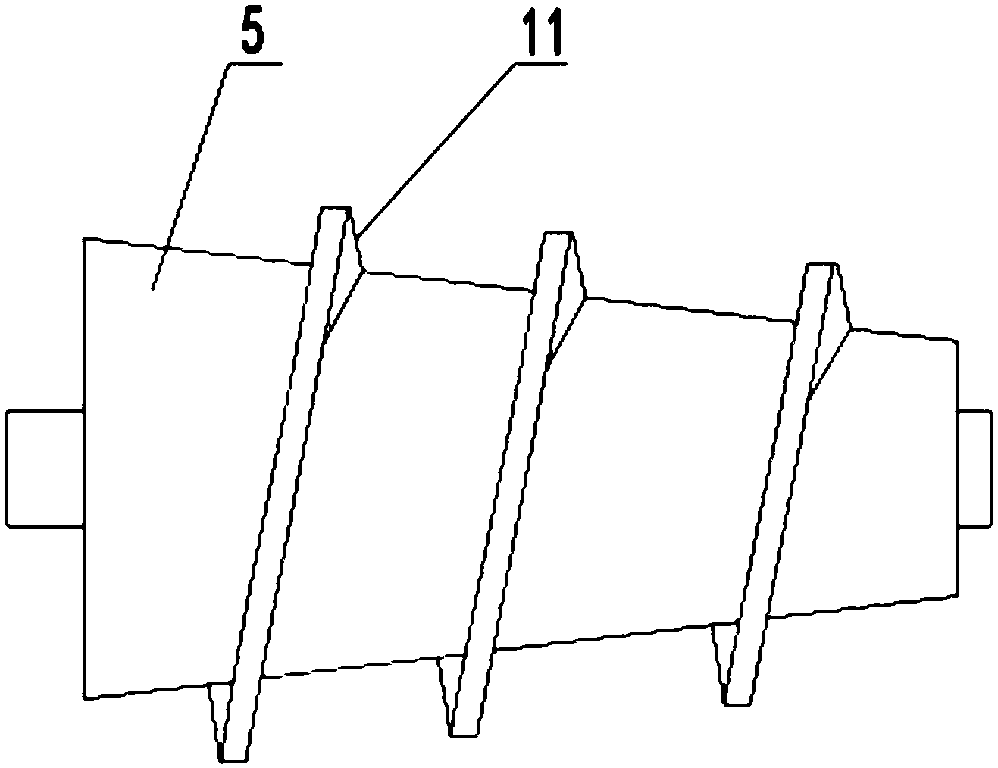

[0020] See Figure 1~3 In the embodiment of the present invention, a corn threshing device for agricultural processing includes a housing 1 fixed on a bracket 2 and a drive motor 3. The housing 1 is installed with a rotating shaft 4 concentric with it, and the outside of the rotating shaft 4 is fixed There is a roller body 5, the shell 1 is also fixed with a threshing shell 6 through a mounting bracket 8. Both ends of the threshing shell 6 have openings, the threshing shell 6 encapsulates the roller body 5 inside, and the inner wall of the threshing shell 6 is fixed There are a plurality of threshing teeth 7 and a plurality of leakage holes 9 are provided on the inner wall of the threshing shell 6 to facilitate the falling of the separated corn kernels. There is a gap on the surface of the threshing shell 6 and the roller body 5 to form a threshing cavity 10. A spiral blade 11 is fixed on the outside of the roller body 5. When corn enters the threshing chamber 10, it is driven ...

Embodiment 2

[0022] See figure 1 In the embodiment of the present invention, the surfaces of the threshing shell 6 and the roller body 5 have a taper, so that the space of the threshing chamber 10 is gradually reduced along the feeding direction of the spiral blade 11. When the corn cob enters the threshing chamber 10, Regardless of the size of the corn cob, it can make the corn cob and the threshing gear 7 have good contact, the threshing effect is good, and the threshing is more thorough.

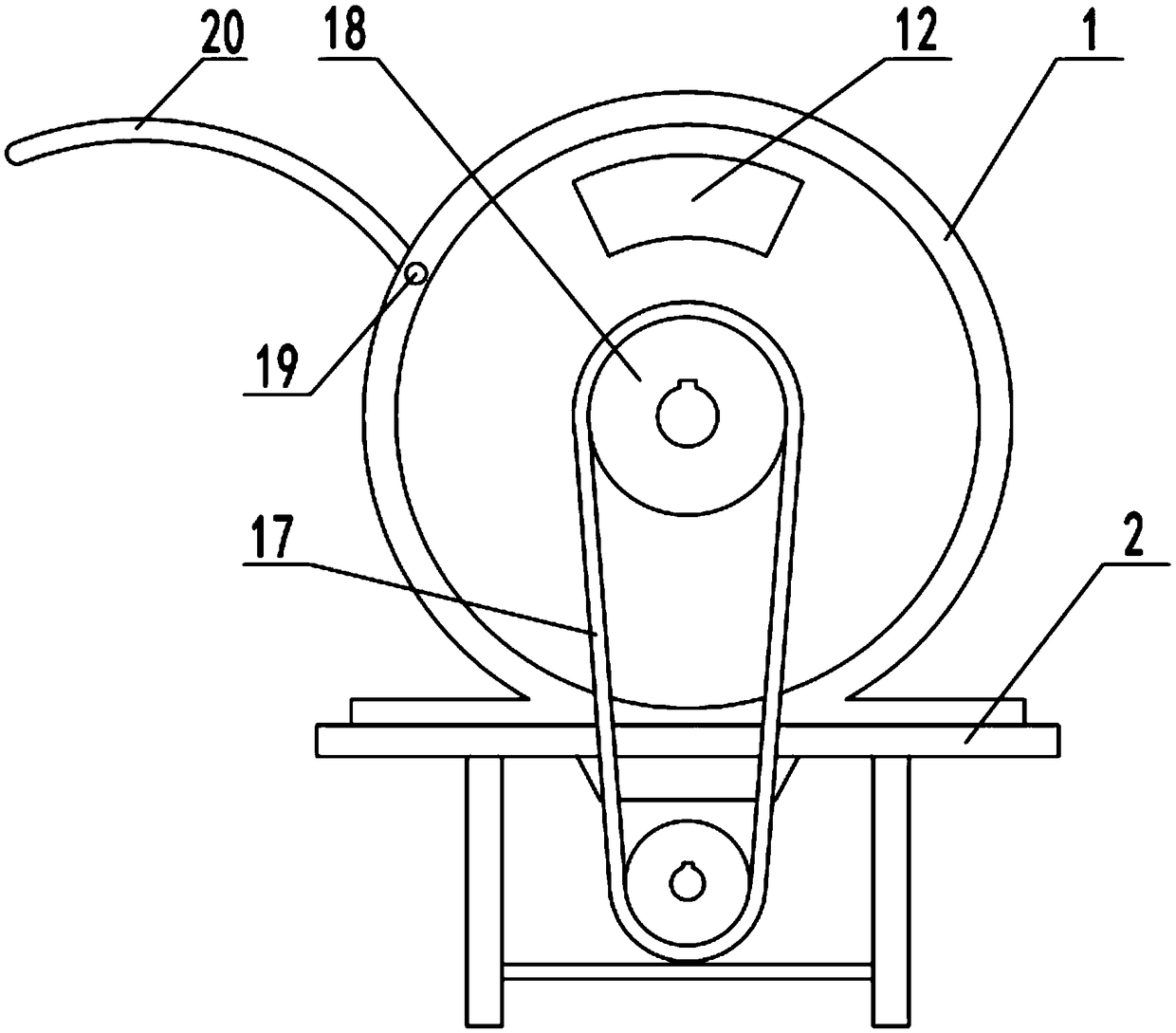

[0023] In addition, this embodiment further describes the transmission structure. Specifically, the transmission structure includes a driving pulley 16, a timing belt 17, and a driven pulley 18. The driving pulley 16 and the driven pulley 18 are respectively Installed at the output end of the drive motor 3 and the shaft end of the shaft 4, the driving pulley 16 and the driven pulley 18 are connected by a timing belt 17, when the driving motor 3 outputs power, the driving pulley 16 can drive the driven Th...

Embodiment 3

[0025] See figure 2 In the embodiment of the present invention, a corn threshing device for agricultural processing further includes a door body 20 which is hingedly mounted on the housing 1 through a pin 19, and the door body 20 can be opened to the inside during operation. Observe the working process, or open the door body 20 to inspect and repair internal components; in order to meet the requirements of movement, the bottom of the bracket 2 can also be equipped with moving wheels to facilitate the movement of the whole mechanism.

[0026] It should be noted that in this technical solution, the relative movement of the threshing shell 6 and the roller body 5 can realize the threshing effect on the corn. At the same time, the surface of the threshing shell 6 and the roller body 5 have a taper, regardless of the size of the corn cob. All of them can make good contact between the corn cob and the threshing gear 7, the threshing effect is good, the threshing is more thorough, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com