self-propelled sunflower harvester

A harvester, self-propelled technology, applied in the direction of harvesters, agricultural machinery and implements, threshing equipment, etc., can solve the problems of inability to separate sunflower seeds from sunflower trays, affecting the harvesting process, and inability to downstream classification, etc., to achieve good harvesting, Efficient threshing and separation, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

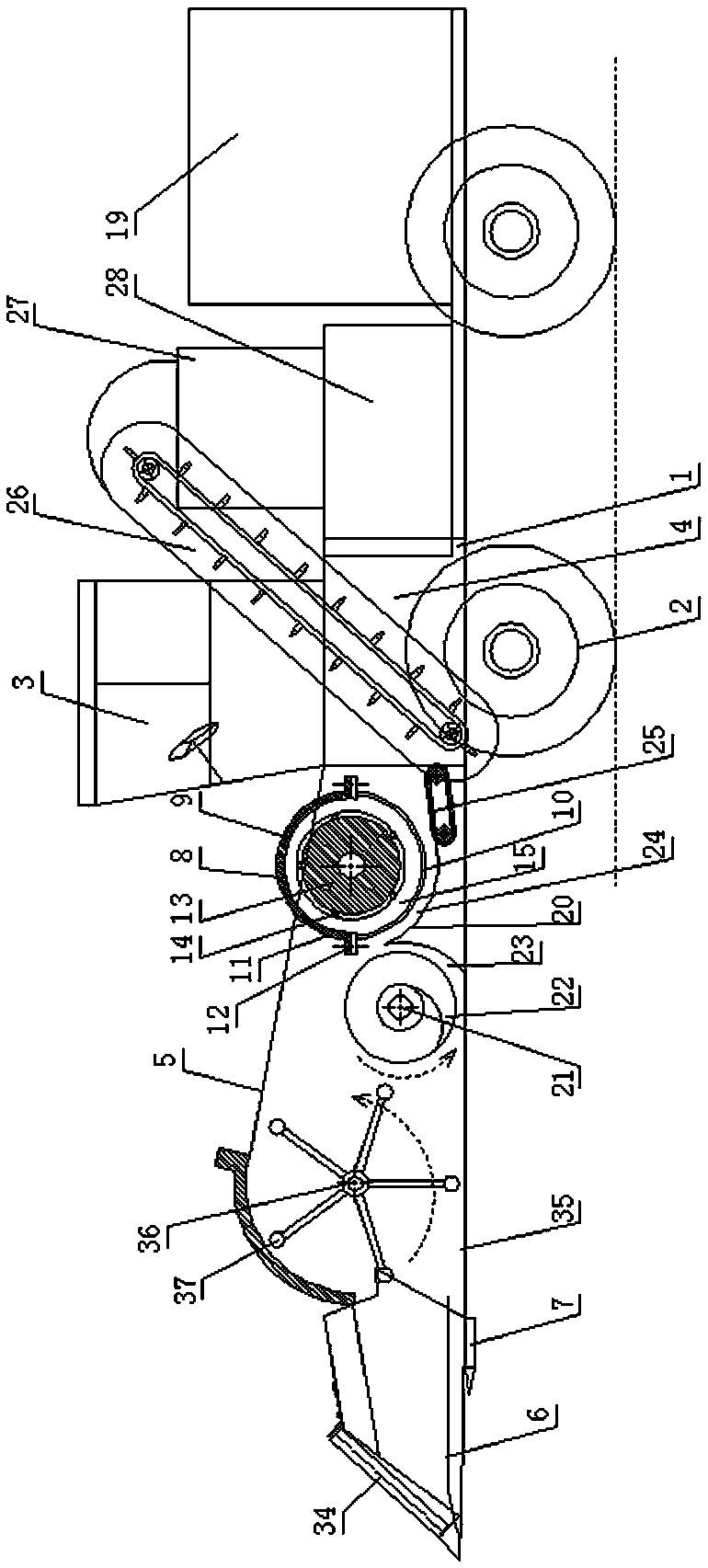

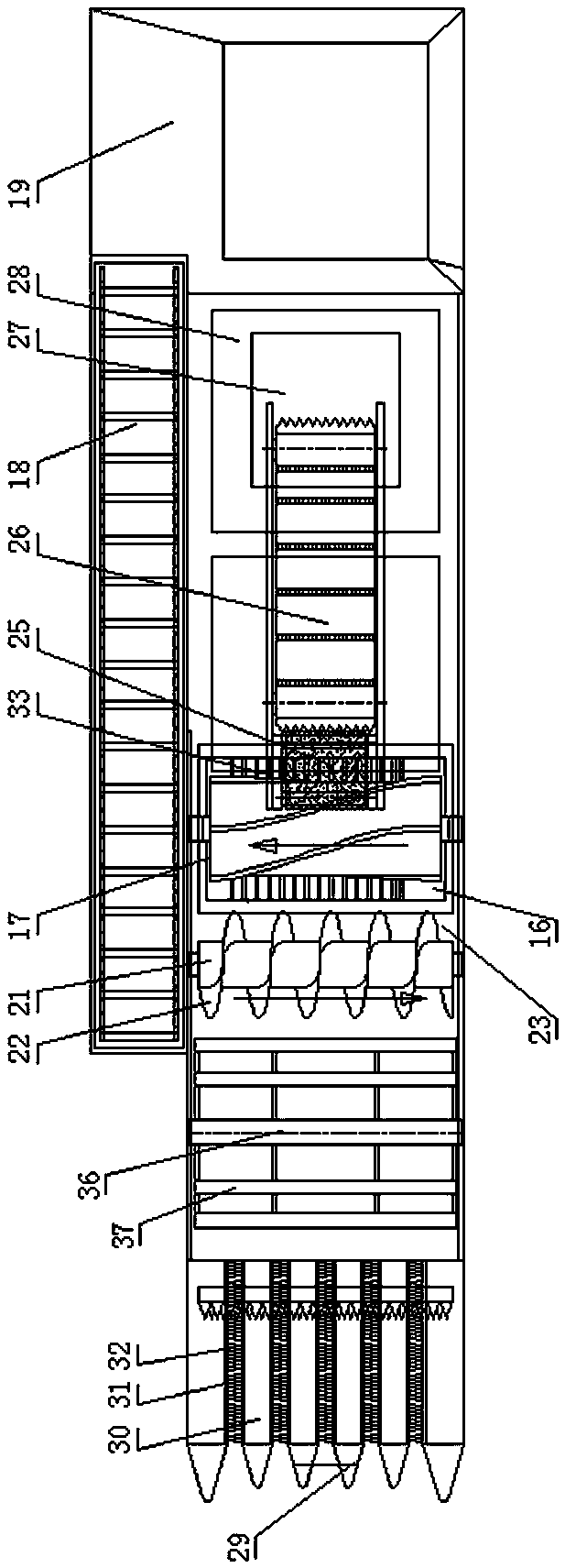

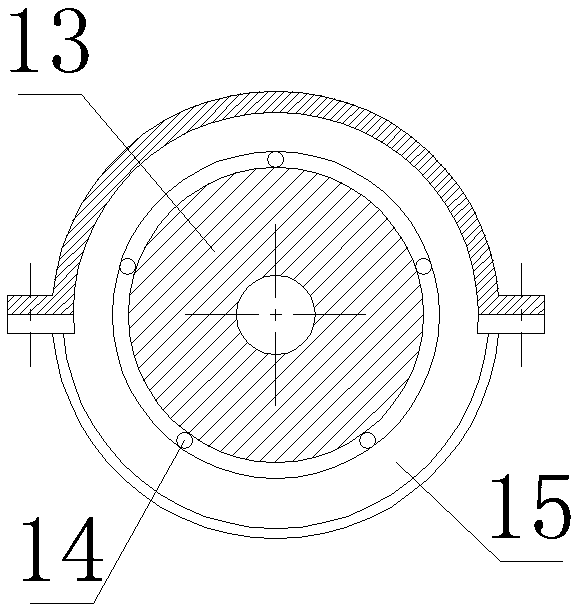

[0043] Below in conjunction with accompanying drawing, self-propelled sunflower harvester of the present invention is described in detail below.

[0044] As shown in the accompanying drawings, the self-propelled sunflower harvester of the present invention has a structure comprising a vehicle frame 1, wheels 2, a cab 3, a power mechanism 4, and the front end of the vehicle frame 1 is provided with a cultivating platform frame 5,

[0045] The front end of the cultivating platform frame 5 is set as a harvesting platform 6, and the cultivating platform frame below the harvesting platform 6 is provided with a sunflower stalk cutter 7;

[0046] The plowing platform frame at the harvesting platform 6 rear is provided with a feeding platform 35, the feeding platform 35 is provided with a frame-type feeding roller 36, and the outer periphery of the frame-type feeding roller 36 is provided with a feeding frame driving lever 37;

[0047] The tillage platform frame behind the tangent lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com