Combing and threshing tooth for miniature semi-feed combine harvester

A technology of combine harvester and comb-off teeth, applied in the field of comb-off teeth, can solve the problems of inability to help grain conveying, unable to prevent grain splashing, and low rice conveying efficiency, so as to prevent the loss of grain splashing, improve grain conveying efficiency and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

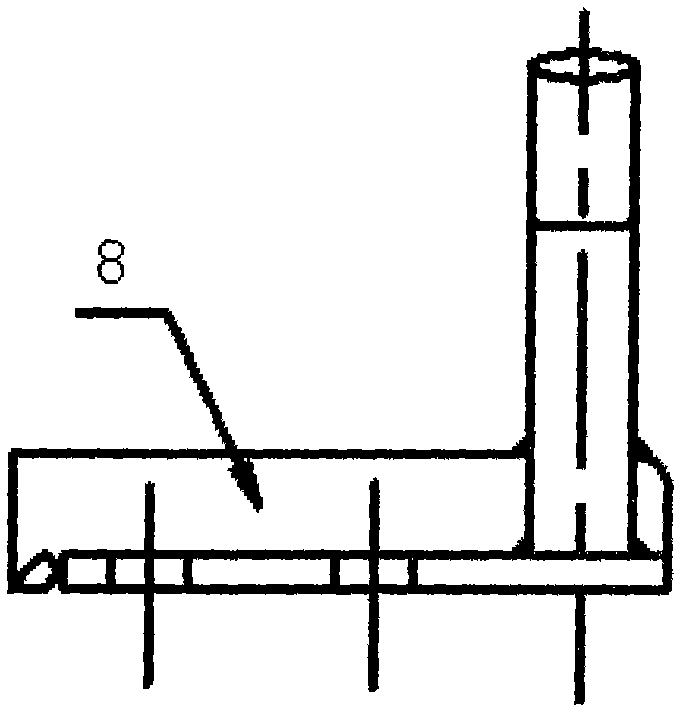

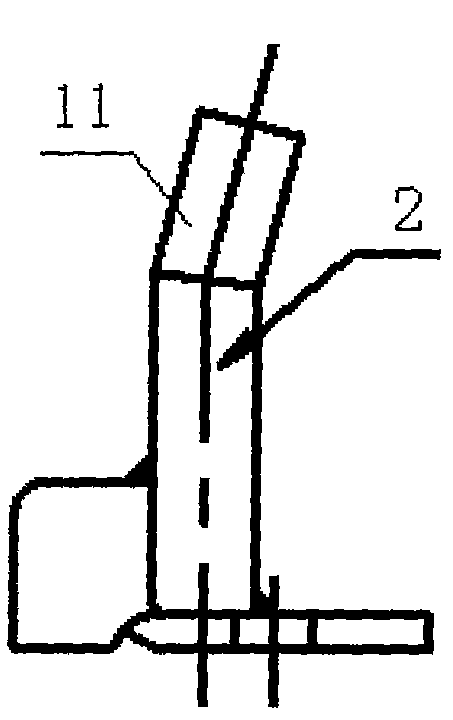

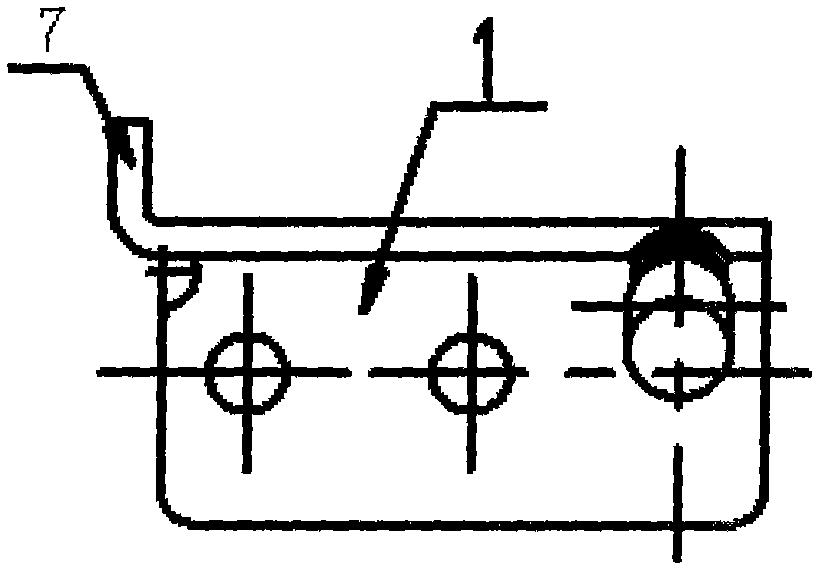

[0026] The preferred embodiment of the present invention is like this, with reference to Figure 1- Image 6 , Comb tooth is made up of nail tooth 2 and each baffle plate, and the nail tooth 2 is welded on the different positions of baffle plate according to the situation of each combing off position so as to form a set of comb tooth shapes with different tooth shapes. A full set of comb stripping teeth is installed on the comb stripping belt, referring to the direction of entry and exit of rice stalks as left-in and right-exit and tooth-shaped structure. The first comb takes off the teeth 11 and is installed on the leftmost side of the strip, because the left side of the comb is to enter the grass mouth. The first comb takes off the teeth 11 and has the left hook and the nail teeth 2 and the nail teeth 2 are welded on the right side of the teeth, so The tooth shape is more suitable to be arranged at the entrance of the rice stalk. There are more rice on the entrance rice stalk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com