Liquid blocking device of rotary drum vacuum filter

A rotary drum vacuum and filter technology, applied in filtration and separation, moving filter element filters, separation methods, etc., can solve problems such as poor use effect, uneven thickness of filter cake, and rotary drum vacuum leakage, and ensure product output. and quality, avoid splash loss, reduce the effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below in conjunction with the accompanying drawings.

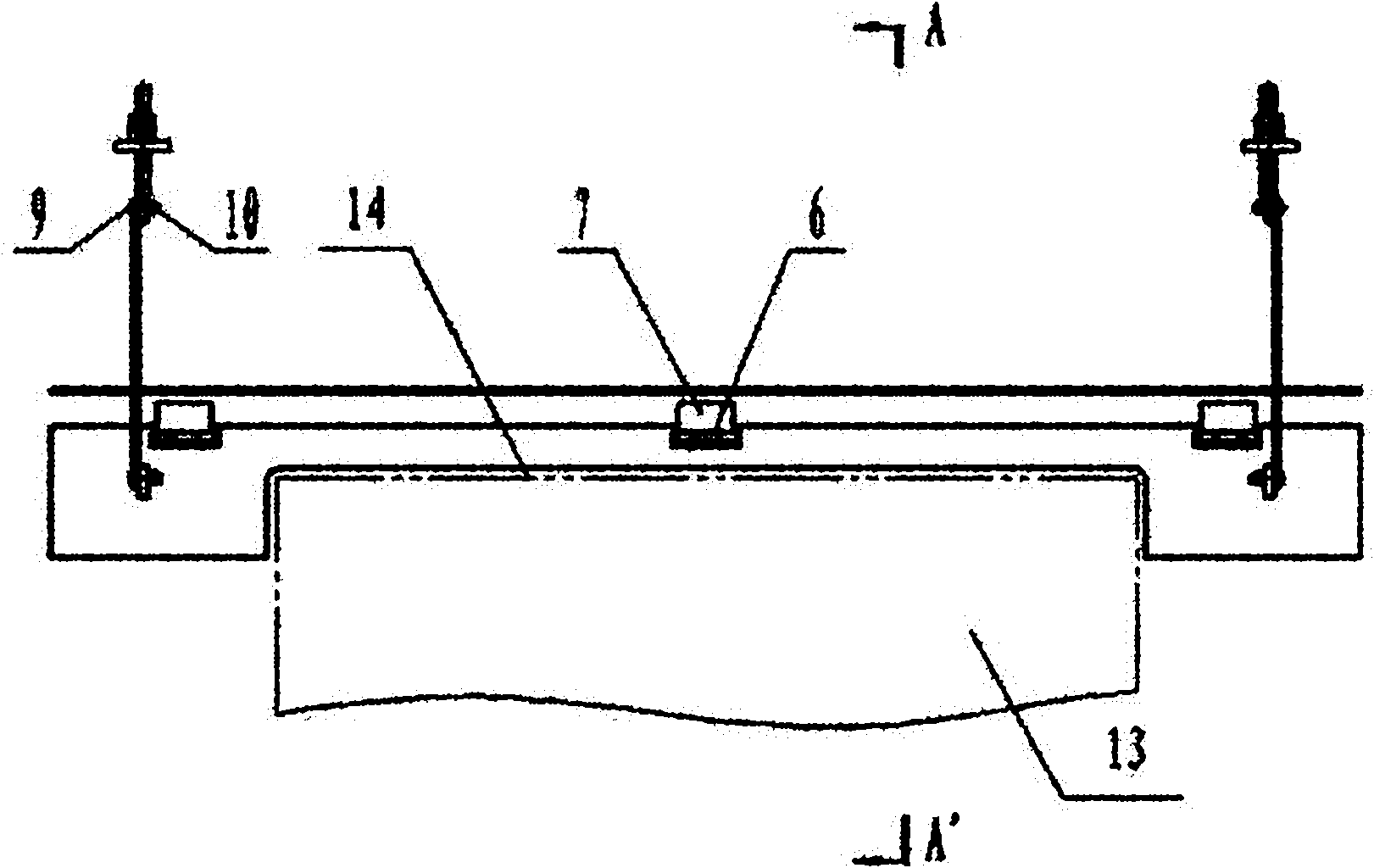

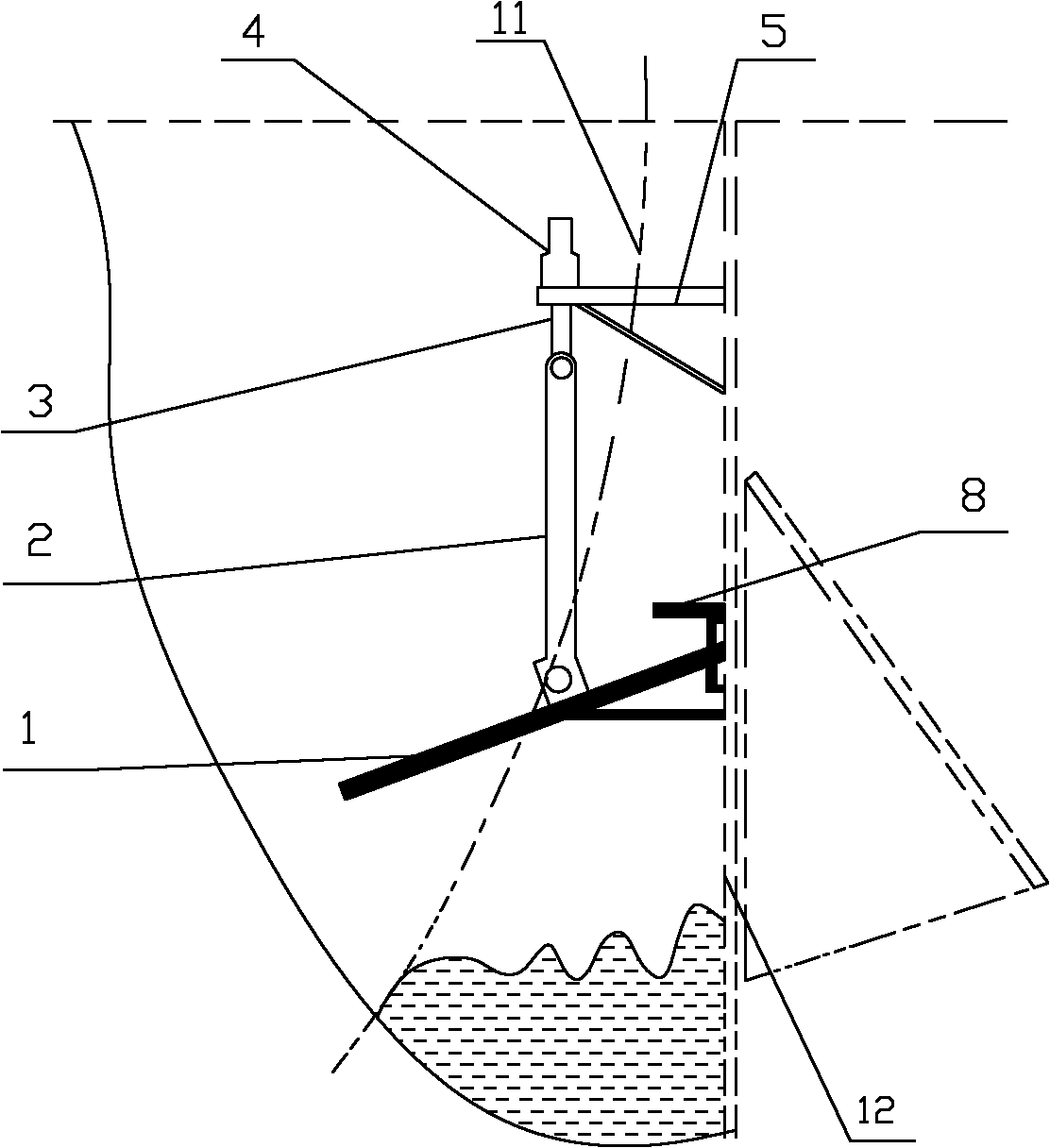

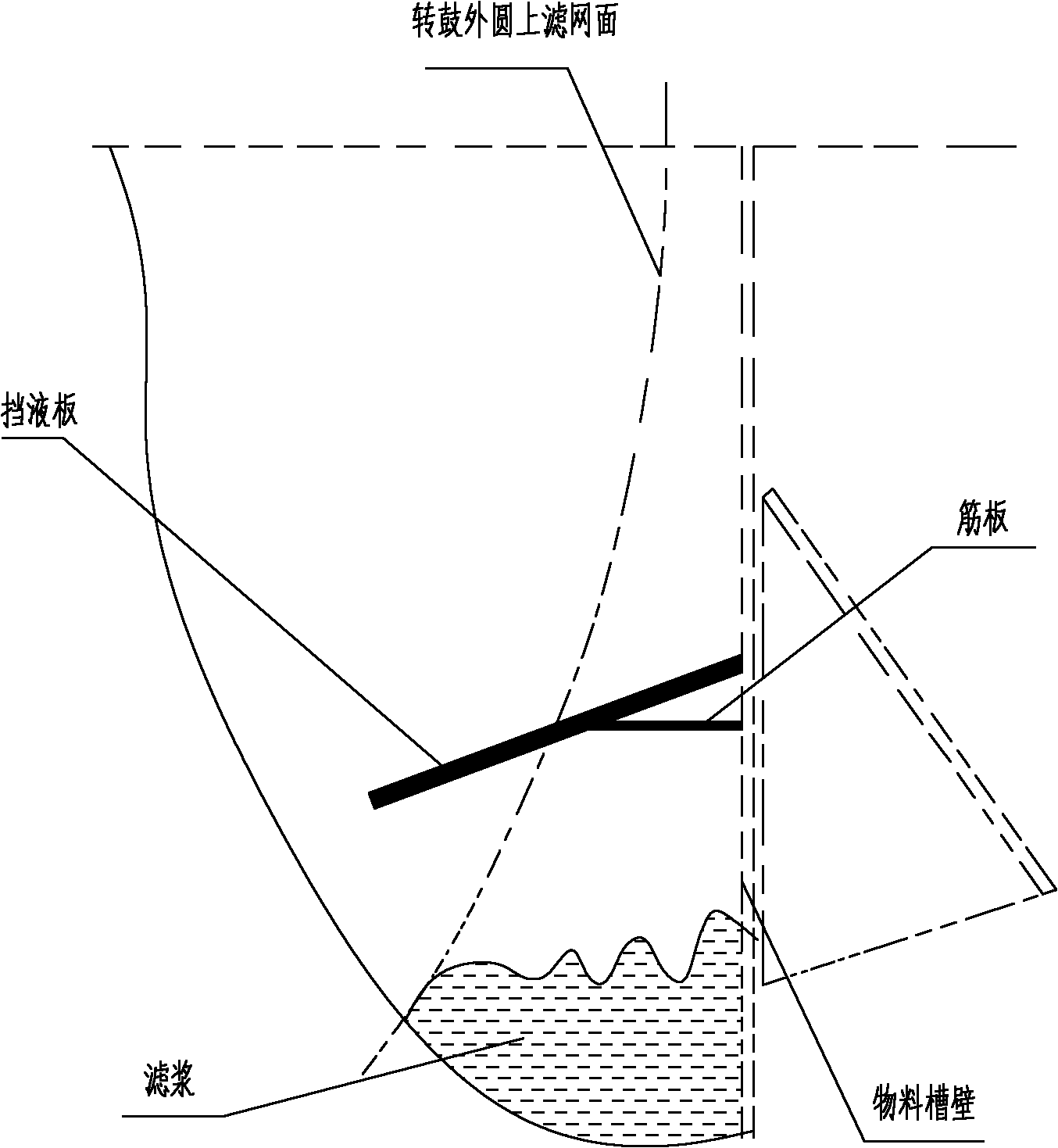

[0016] Such as figure 2 , image 3 As shown, a liquid blocking device for a drum vacuum filter includes a liquid blocking plate 1, a drum 13 and a slurry tank wall 12, and one side of the liquid blocking plate 1 is connected to the slurry tank wall 12, and the specific connection method is that the liquid blocking plate One end of 1 is connected to the slurry tank wall 12 through a fixed plate 7 and a hinge 6, and the other side of the liquid baffle 1 is close to the filter medium 11 on the drum 13. A rectangular auxiliary baffle 8 connected to the slurry tank wall 12 is provided above the gap 14 between the liquid baffle 1 and the slurry tank wall 12 to block the spray that may come from the gap 14 between the liquid baffle 1 and the slurry tank inner wall. liquid, allowing it to return to the slurry tank. The liquid baffle (1) is also provided with a connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com