Oil supplying device

An oil supply device, valve device technology, applied in liquid cooling, engine components, machines/engines, etc., can solve problems such as aging, increased emissions, splash loss, etc., to prevent oil aging, reduce emissions, and reduce splash loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

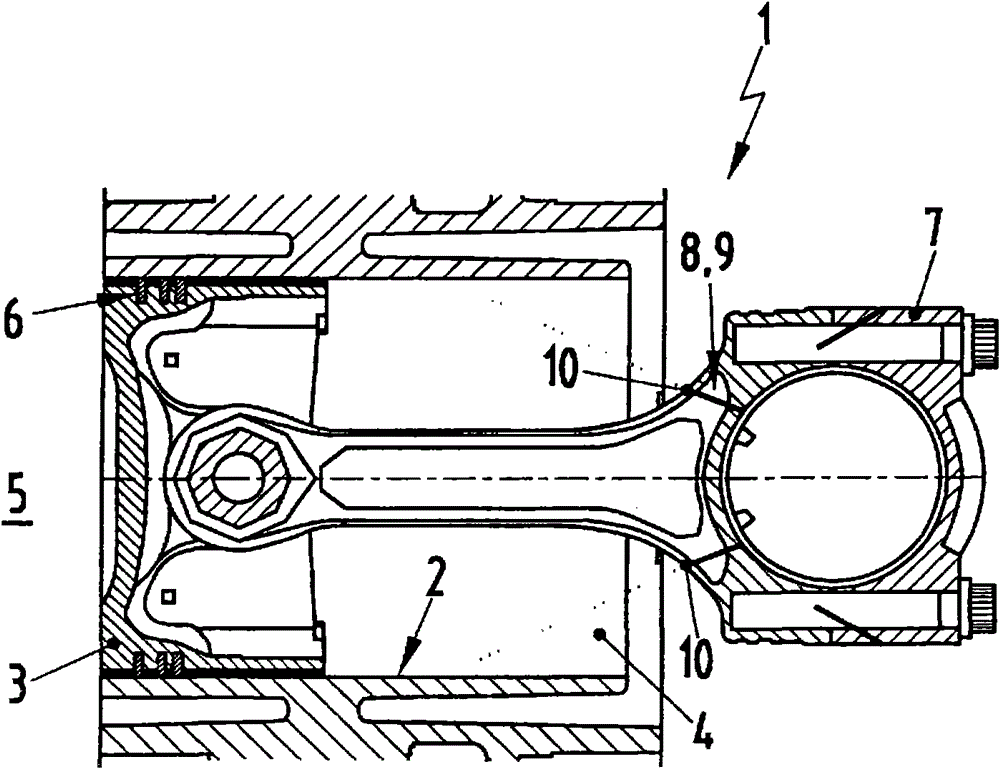

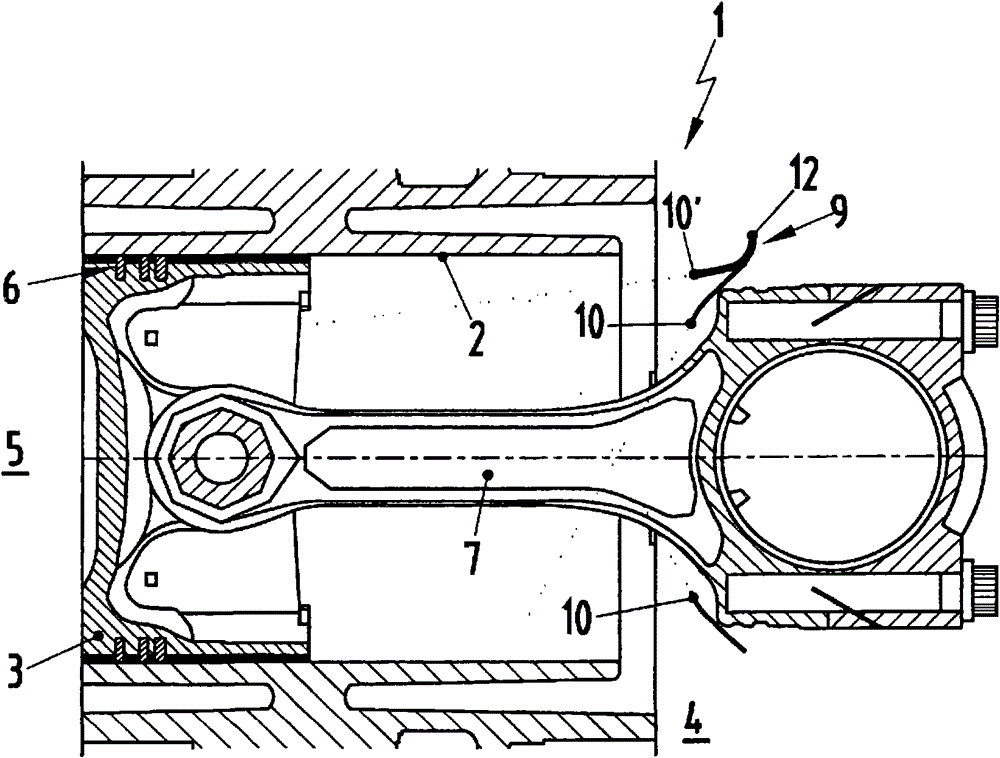

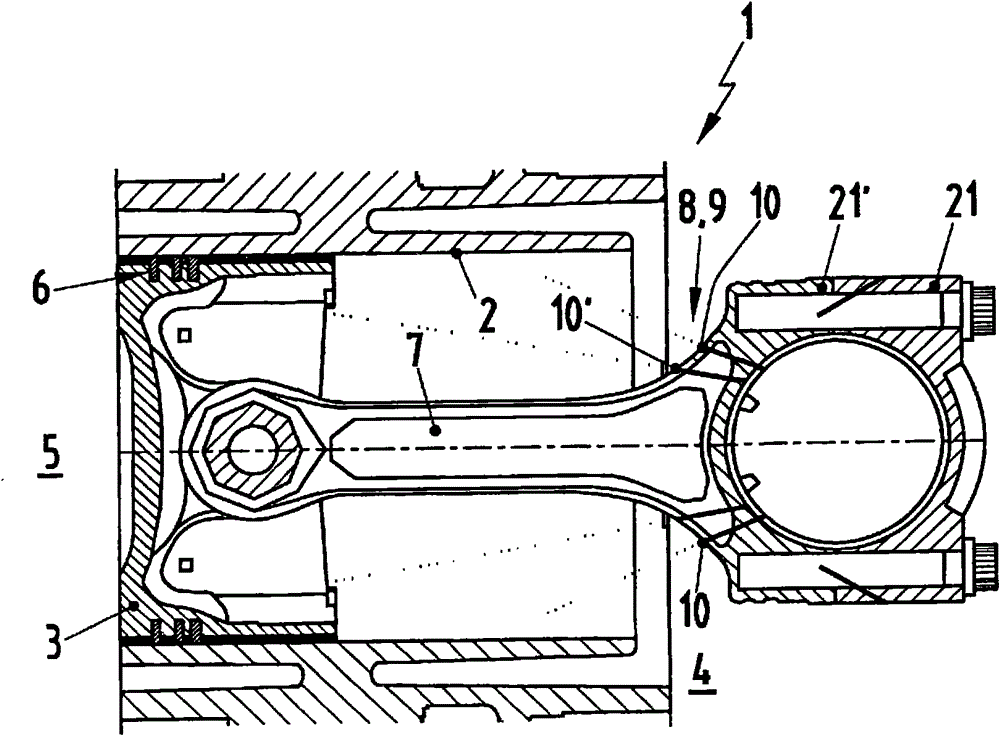

[0029] according to Figure 1 to Figure 3 , a piston-cylinder assembly 1 has in each case a piston 3 which can reciprocate in a cylinder 2 in a translational manner. Piston-cylinder assembly 1 can be embodied here as an internal combustion engine, in particular in a motor vehicle. In order to seal a crankcase interior 4 from a combustion chamber 5, so-called piston rings 6 are conventionally arranged on the piston 3, which are inserted into an outwardly open annular recess on the piston skirt. Groove and extended slide in cylinder 2. as from figure 1 It can also be seen that a connecting rod 7 has an oil supply device 9 arranged therein (see Figure 4 and Figure 5 ), the oil supply device has at least one oil nozzle 10, which is directed to the cylinder 2 and is used to lubricate the cylinder working surface. Another oil nozzle 10' can for example be directed towards the piston 3 (see figure 2 and image 3 ) and oil is sprayed onto said piston 3 at least temporarily i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com