A kind of wheat threshing device

A threshing device, wheat technology, applied in threshing equipment, agricultural machinery and tools, agriculture, etc., can solve the problems of accelerated slag decay and degradation speed, device blockage, poor effect, etc., to ensure integrity, facilitate collection, reduce Effects of Pollution Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

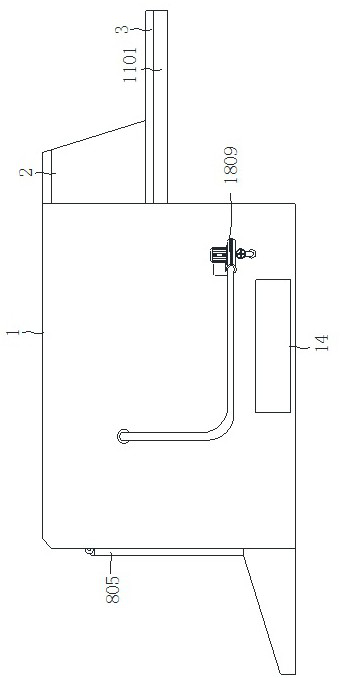

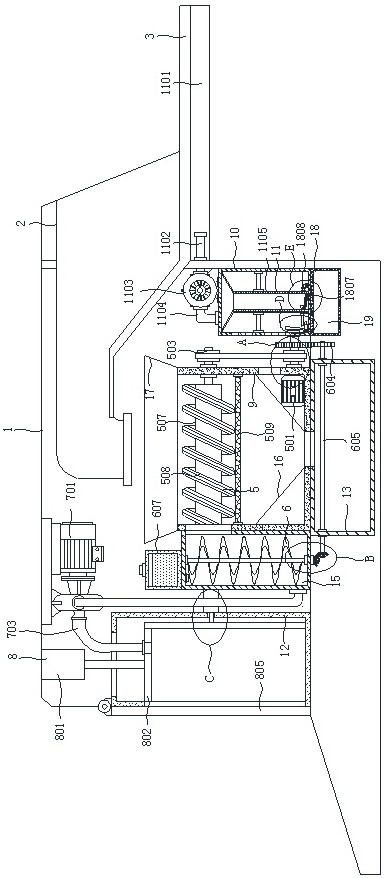

[0039] see Figure 1-6, the present invention provides a wheat threshing device, comprising a main body 1, a feed port 2 and a conveyor belt 3 are arranged on one side of the main body 1, a threshing mechanism 5 is arranged inside the main body 1, and a crushing mechanism 6 and a block making mechanism are also arranged inside the main body 1 8. A separation box 9 is fixedly installed inside the main body 1, and the top of the separation box 9 is fixedly connected to the hopper 17, and the hopper 17 communicates with the inside of the separation box 9;

[0040] The inside of the main body 1 is provided with a dust removal box 10, a compression box 12, a carrying box 13 and a crushing box 15; During use, wheat enters the device from the feed port 2 and falls into the separation box 9 for threshing.

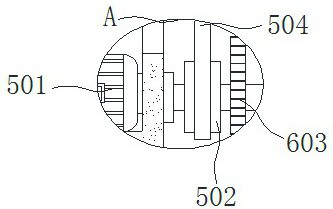

[0041] The threshing mechanism 5 comprises a motor 501, a roller 507, a spiral plate 508 and a screen cloth 509;

[0042] The motor shaft of the motor 501 is linked with the firs...

Embodiment 2

[0049] On the basis of Embodiment 1, the crushing mechanism 6 includes a crushing rod 601 arranged in the crushing box 15, a helical blade 602 is fixedly arranged on the outside of the rod body of the crushing rod 601, and the crushing rod 601 is linked with the motor shaft of the motor 501;

[0050] The motor shaft of the motor 501 is coaxial with the first pulley 502 and the first gear 603, the first gear 603 meshes with the second gear 604, the second gear 604 is coaxially fixed at one end of the transmission rod 605, and the other end of the transmission rod 605 passes through the cone The gear combination 606 is linked with the crushing rod 601;

[0051] The top of the crushing box 15 is provided with a water storage tank 607, the top of the water storage tank 607 is fixedly equipped with a water inlet pipe, and one end of the water inlet pipe communicates with the inside of the water storage tank 607. 607 is internally connected, and the other end of the drain pipe is fi...

Embodiment 3

[0054] On the basis of the above-mentioned embodiments, a suction pump 701 is also provided in the main body 1, and the suction pump 701 is fixedly installed on the inner top of the main body 1, and the input end of the suction pump 701 is fixedly connected with one end of the suction pipe 702, and the suction pipe 702 The other end of the pump extends to the inner bottom of the crushing box 15, and the output end of the suction pump 701 communicates with the inside of the compression box 12 through a suction hose 703.

[0055] This structure facilitates the transportation of crushed straw, prevents the crushed straw from accumulating and blocking in the crushing box 15, and affects the operation of the device, thereby avoiding damage to the motor when it is stopped, and can effectively prolong the service life of the device. Feed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com