Heat detection automatic fire extinguishing device

An automatic fire-extinguishing and temperature-sensing detection technology, applied in fire rescue and other directions, can solve the problems of economic and material waste, long fire-fighting time, insufficient safety, etc., and achieve the effect of ensuring facility safety and convenient disassembly and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

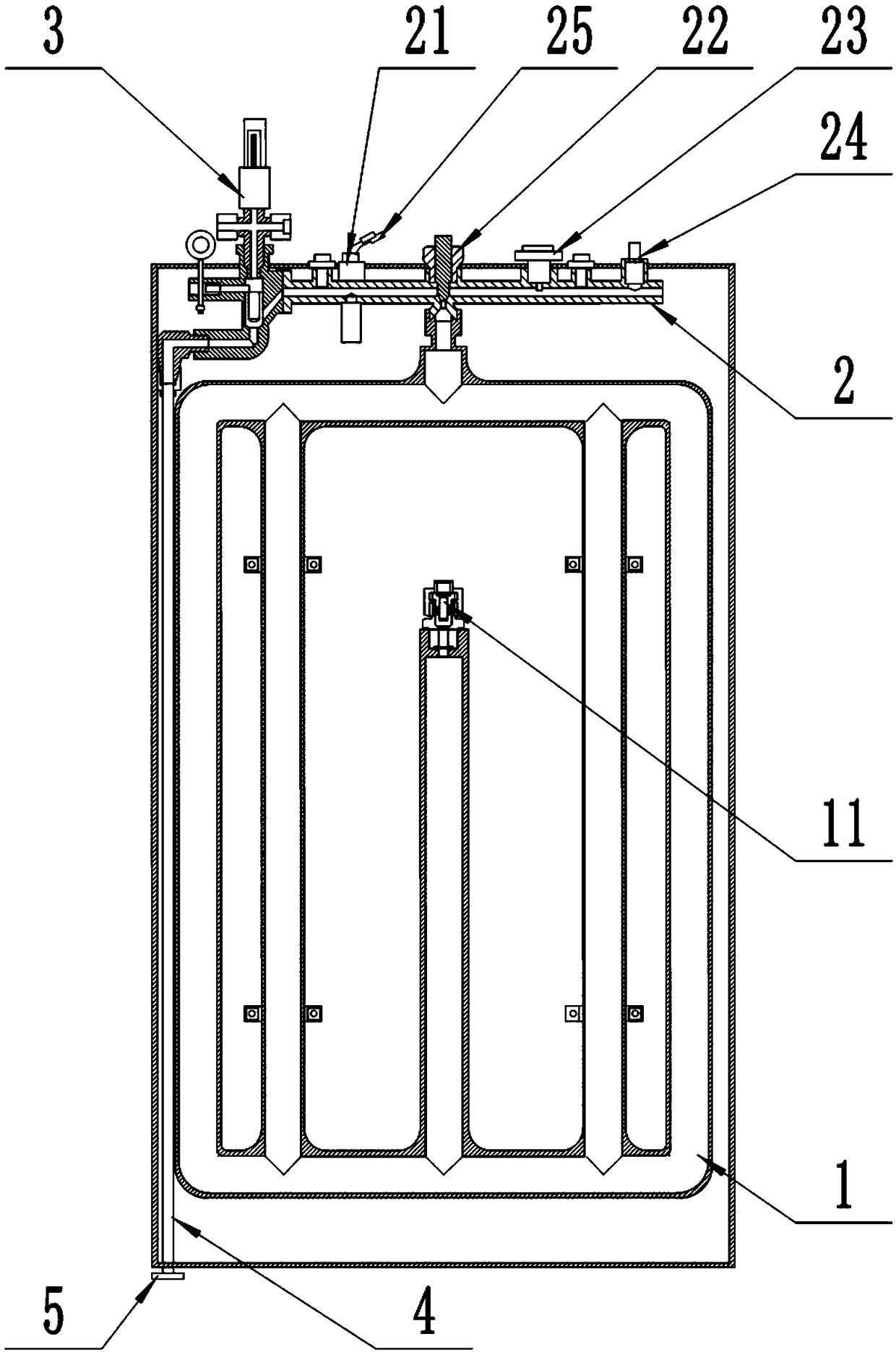

[0033] Example 1: Please refer to Figure 1-3 , a temperature detection automatic fire extinguishing device, comprising:

[0034] A gas storage container 1 for storing fire extinguishing agent;

[0035] Fire extinguishing agent pipe 2 for switching and transporting fire extinguishing agent, the fire extinguishing agent pipe is connected to the gas storage container;

[0036] A temperature-sensing fire extinguishing valve 3 for temperature sensing and controlling the flow of fire extinguishing agent is installed at one end of the fire extinguishing agent pipe;

[0037] The release pipe 4 is used to deliver the fire extinguishing agent passing through the temperature-sensitive fire extinguishing valve to the nozzle for outward release, one end of which is connected to the temperature-sensitive fire extinguishing valve, and the other end is equipped with a nozzle 5;

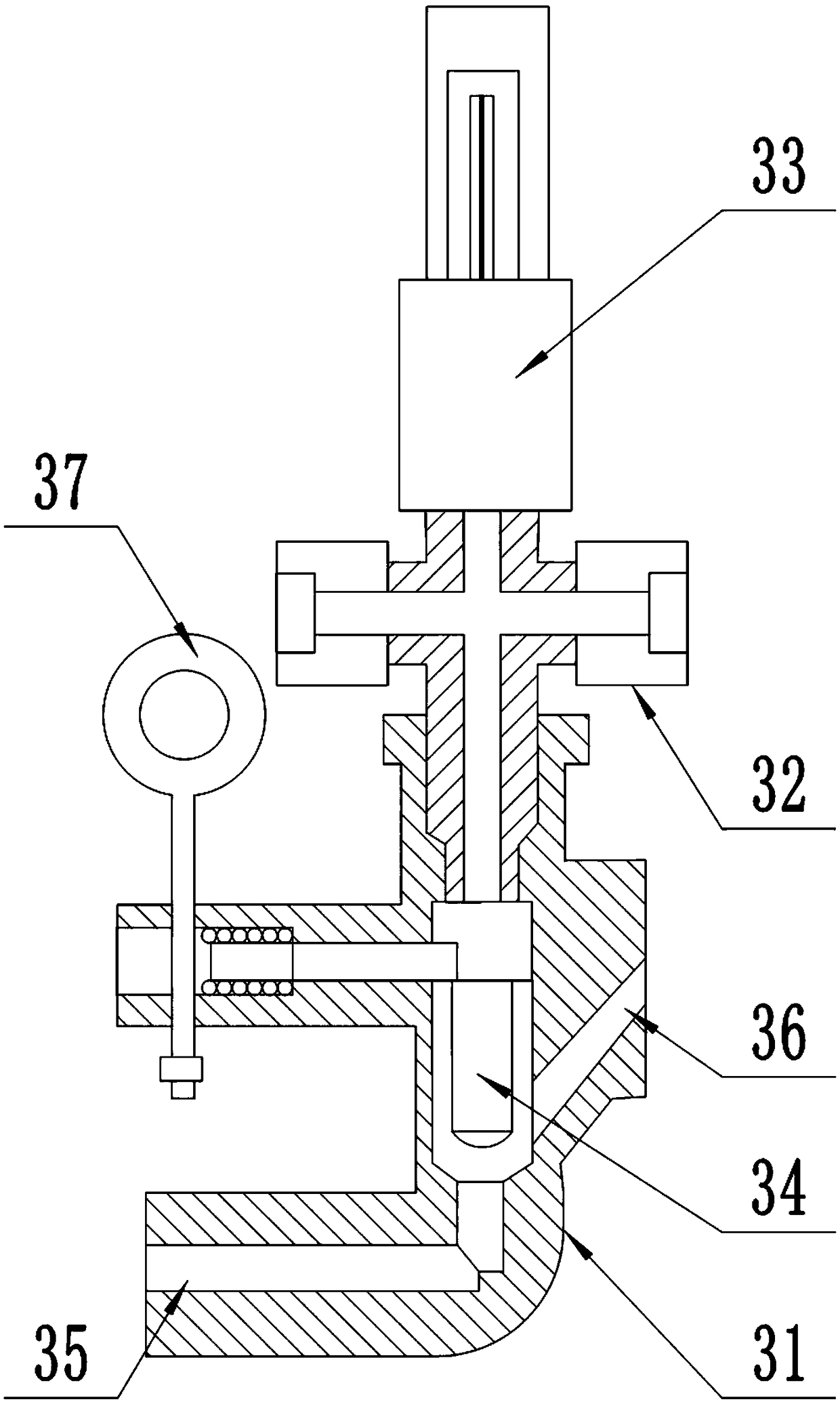

[0038] The temperature-sensitive fire extinguishing valve 3 includes a valve body 31, a four-way joint 32 and a...

Embodiment 2

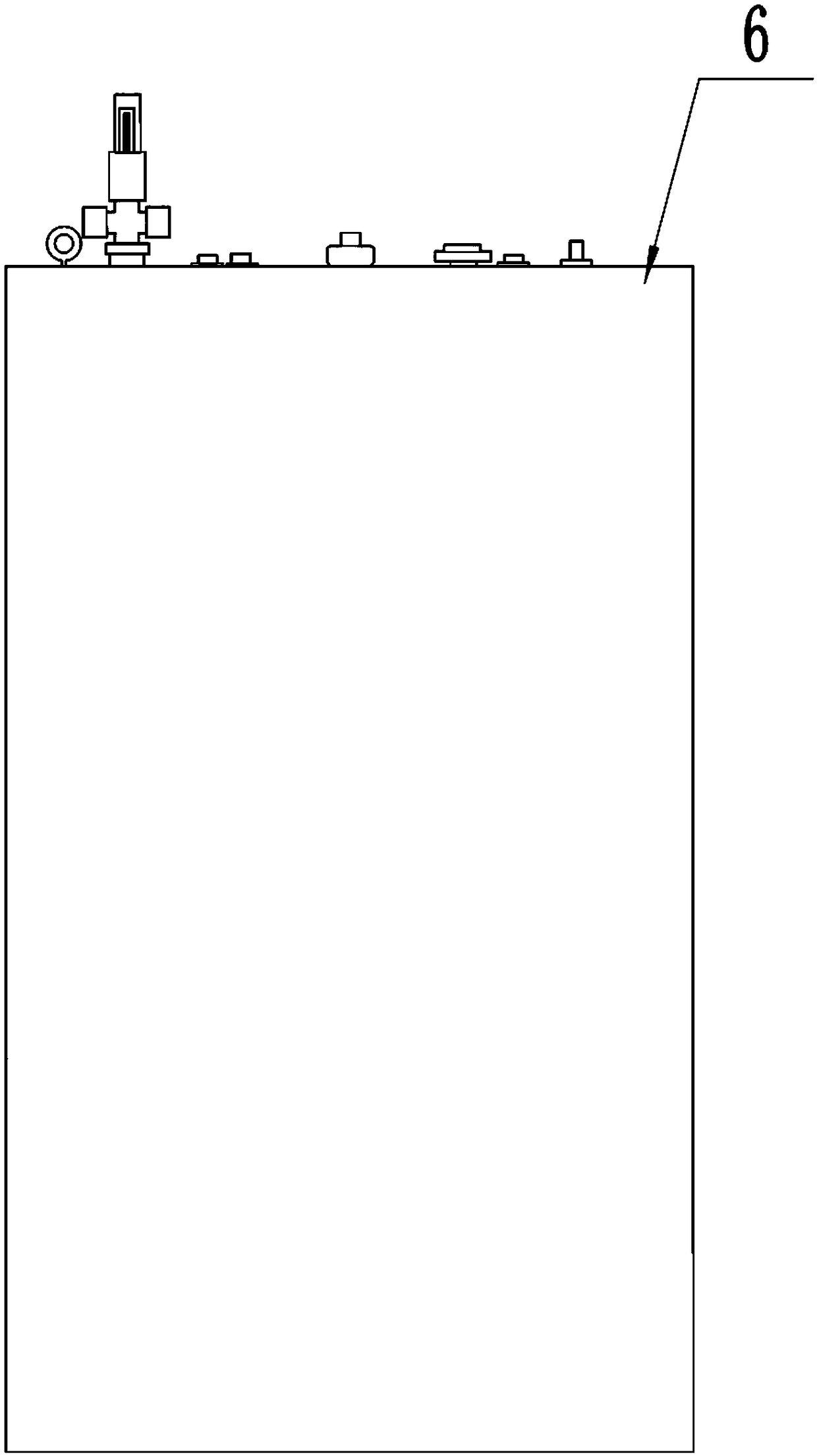

[0048] Example 2: Please refer to Figure 4 The difference between this embodiment and Embodiment 1 is that it includes at least two temperature-sensing automatic fire extinguishing devices 200 connected through compressed air pipes 201, wherein the joints at the left and right ends of the four-way joints of each temperature-sensing automatic fire extinguishing device At least one of the joints is externally connected to the four-way joint of another temperature detection automatic fire extinguishing device through a compressed air pipe, and the joints not connected to the compressed air pipe are sealed; the four-way joint and the compressed air pipe are filled with compressed gas.

[0049] In this embodiment, when the present invention is used for two cabinets or multiple cabinets, when the ambient temperature in the protection zone of the cabinet on fire reaches the set temperature of 68°C, the temperature at the rear end of the temperature detection and automatic fire exting...

Embodiment 3

[0050] Example 3: Please refer to Figure 5 , including a temperature detection automatic fire extinguishing device 300, the outer rear end of the integrated shell of the temperature detection automatic fire extinguishing device is equipped with a closed four-way joint, a signal feedback terminal, a main switch of the air outlet, a pressure gauge and a fire detection pipe interface.

[0051] The difference between this embodiment and Embodiment 1 is that in this embodiment, the glass bulb temperature probe of the temperature-sensitive fire extinguishing valve is removed, and a fire detection pipe 301 is installed and connected to the fire detection pipe interface. When this embodiment is only used for a single cabinet, when the fire detection tube in the fire protection area senses the fire source signal (160°C ± 10°C), the gas in the fire detection tube of the fire cabinet will expand rapidly, and finally will be randomly distributed in the pipeline. A nozzle is blasted out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com