Positioning clamping part for assembling

A clamp and mounting hole technology, applied in the field of computer hardware assembly, can solve the problems of circuit board wear, screw loss, shaking, etc., and achieve the effects of reducing the failure rate, preventing shaking, and reducing the amount of open space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

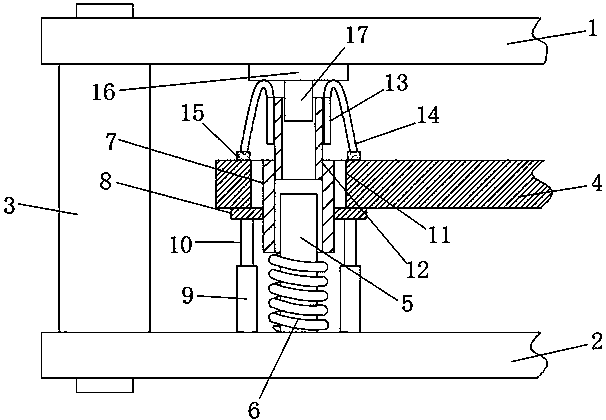

[0013] refer to figure 1 , a positioning clip for assembly, including four upper insertion rods 17 and four lower insertion rods 5, the top ends of the four upper insertion rods 17 are respectively welded with pressure plates 16, and the four pressure plates 16 are respectively welded to the bottom of the cover plate 1 At the four corners of the four corners, the four lower inserting rods 5 are respectively welded to the four corners of the base plate 2, and the corresponding upper inserting rods 17 and the lower inserting rods 5 are arranged coaxially, and the cover plate 1 and the base plate 2 are fixed by screws There is a connecting plate 3, and a spring 6 is sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com