Adjustable mud scraping system of static pressure pile machine

A static pressure pile machine, adjustable technology, applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems such as inconvenient to adapt to piles, time-consuming and laborious, sticking a lot of soil, etc., to achieve easy maintenance, Ease of disassembly and prevention of through-hole misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

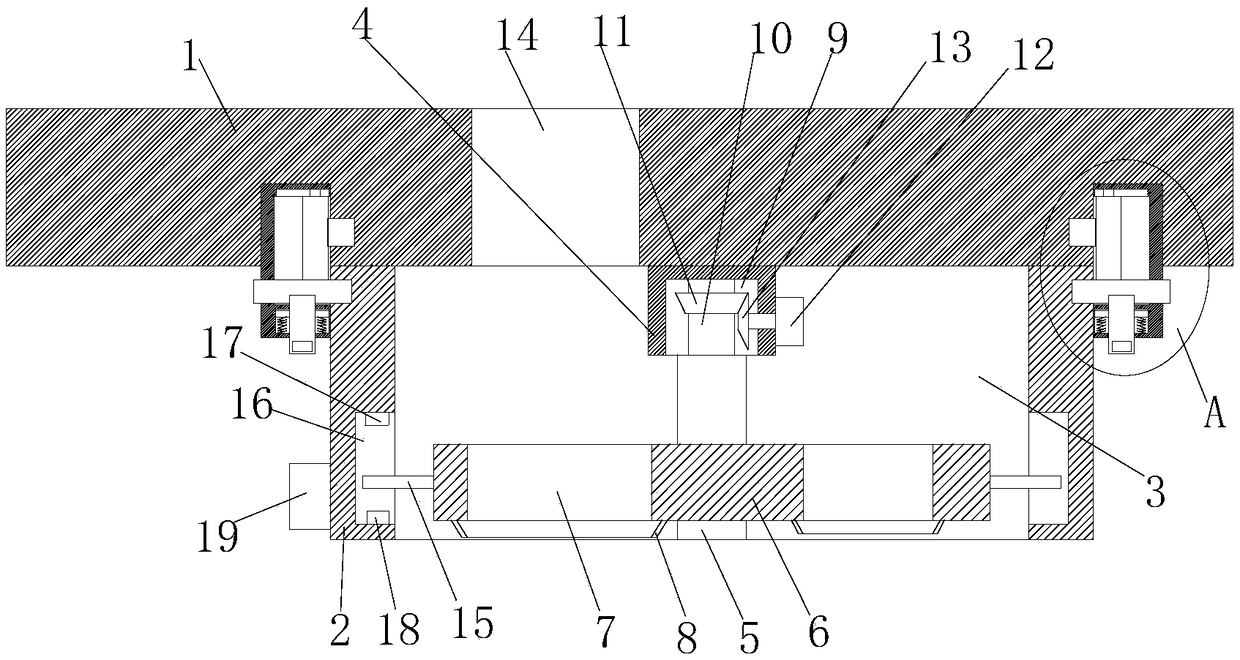

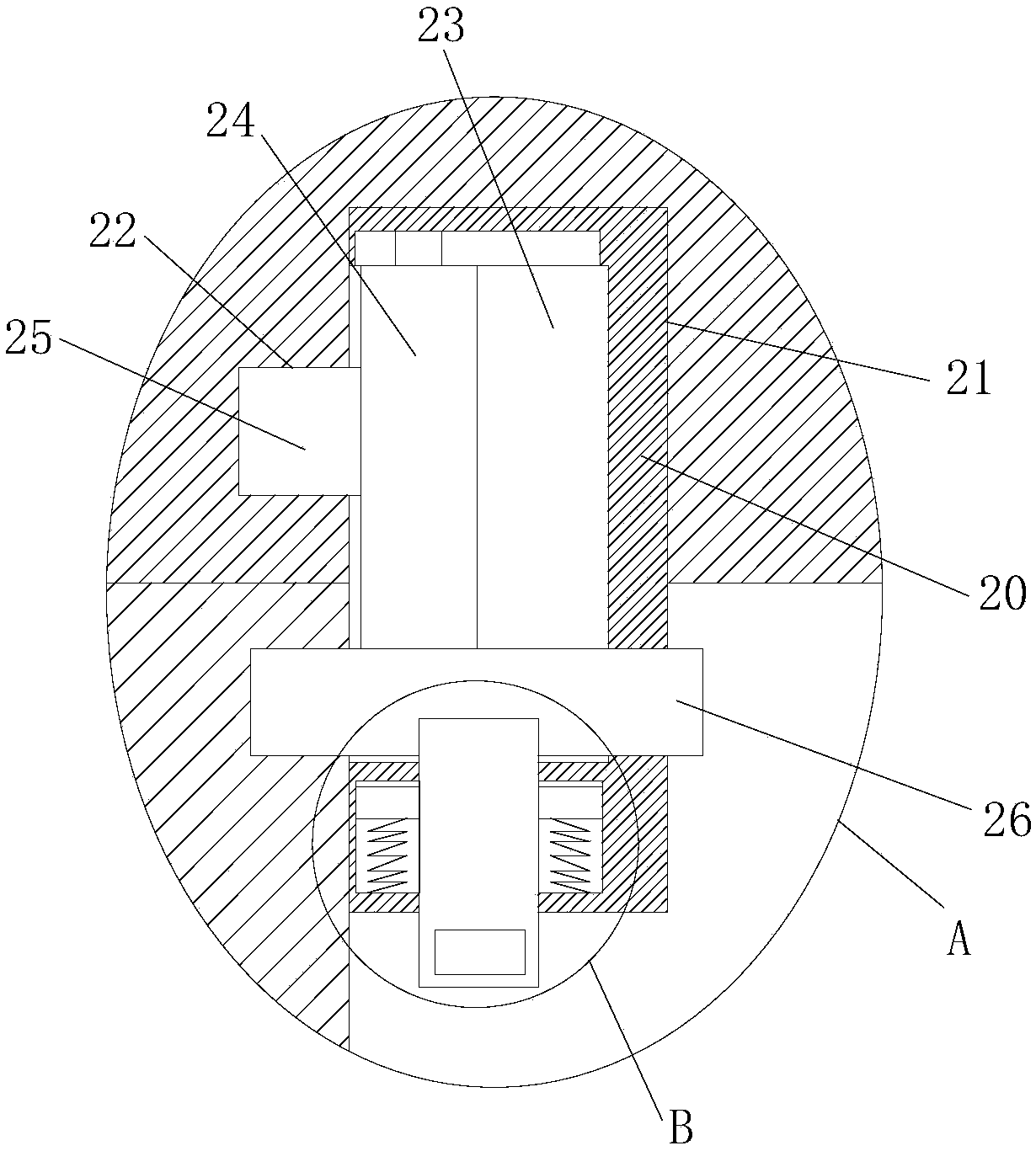

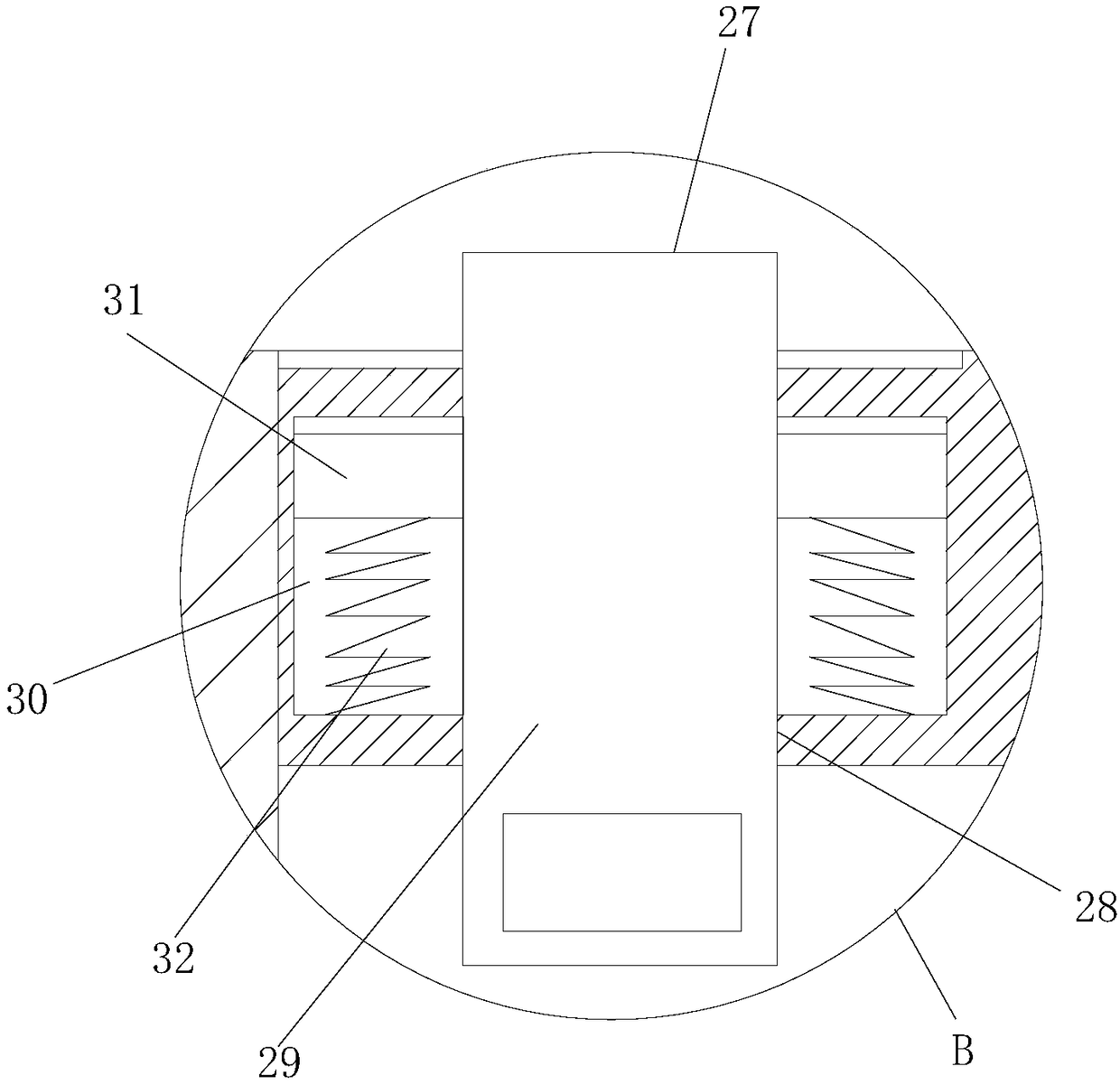

[0026] refer to Figure 1-5, the present embodiment proposes an adjustable mud scraping system for a static pressure pile machine, including a mounting plate 1, a bottom plate 2 is installed on the bottom of the mounting plate 1, and a mounting hole 3 is opened on the bottom plate 2, and the two sides of the mounting hole 3 The same installation block 4 is fixedly installed on the inner wall, and the bottom of the installation block 4 is provided with an installation groove 9, and a rotating column 10 is installed on the top inner wall of the installation groove 9, and the bottom of the rotating column 10 is equipped with an installation rod 5, and the installation rod 5 A turntable 6 is fixedly installed on the outer side of the turntable 6, and a plurality of through holes 7 are opened on the turntable 6, and a plurality of conical cylinders 8 are welded on the bottom of the turntable 6, and the plurality of conical cylinders 8 are all located in the installation hole 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com