Self-adaptive locking mechanism for box body

A locking mechanism and self-adaptive technology, which is applied in the direction of locking equipment, building structures, building fastening devices, etc., can solve the problem that the axial output force of the locking mechanism meets the target requirements, limited space size, and processing errors Problems such as large locking force and pull-out force of the locking mechanism achieve the effects of low installation difficulty, reasonable structure distribution, and less reprocessing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

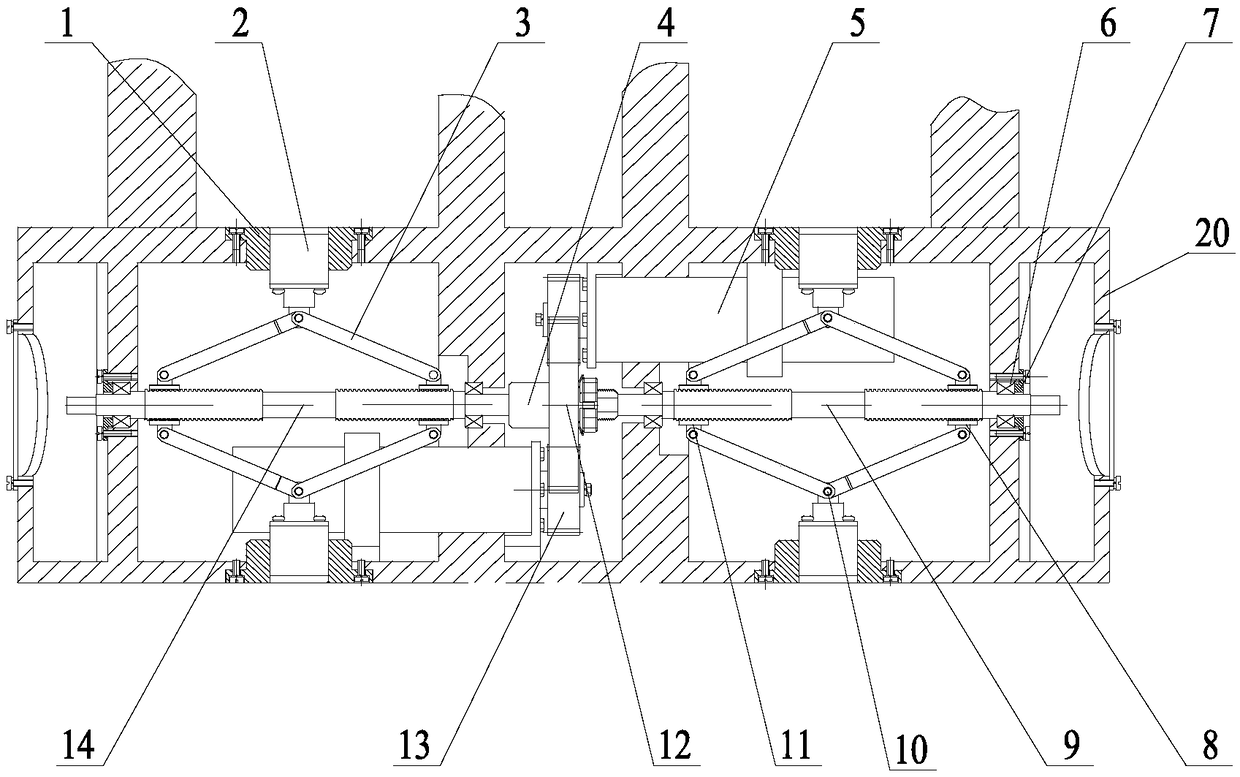

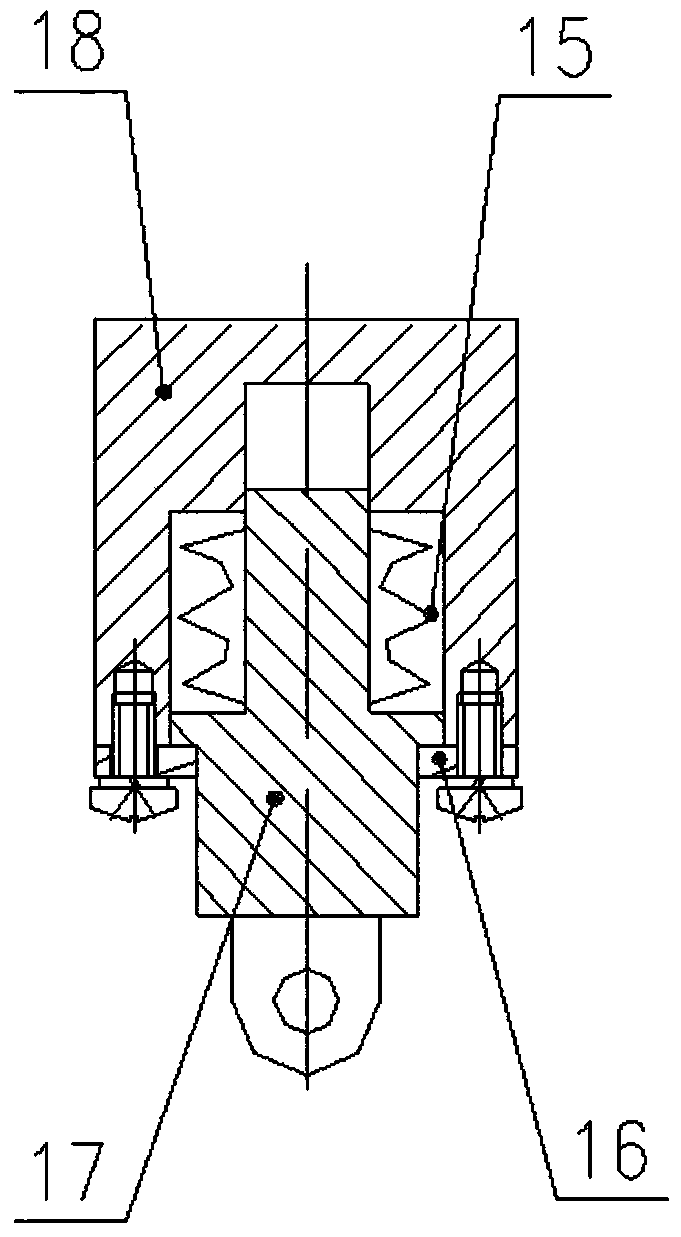

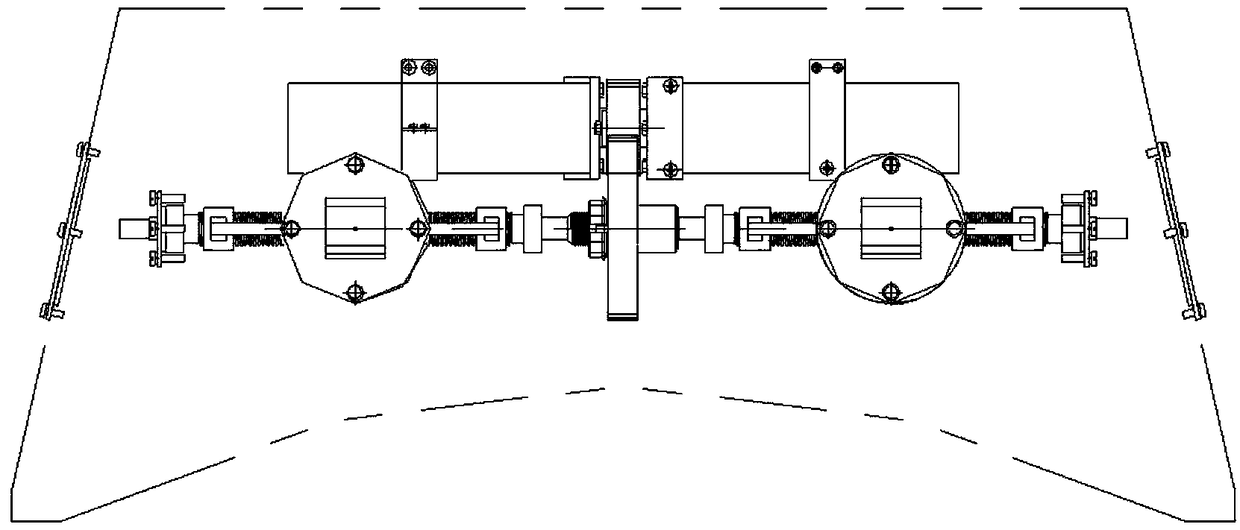

[0025] Such as Figure 1 to Figure 5 The box adaptive locking mechanism shown includes a transmission link 3, an air motor 5, an active tooth 13, and a support stand 20; the air motor 5 is fixed inside the support stand 20, and the air motor 5 drives The tooth 13 drives a screw to rotate, the screw is covered with a nut, one end of the transmission connecting rod 3 is hinged on the lug of the nut, the other end of the transmission connecting rod 3 is hinged on the bottom of the locking pin combination 2, and the locking pin combination 2 is set In the outer wall hole of the support stand 20.

[0026] The number of the air motors 5 is two, and the driving teeth 13 on the two air motors 5 are engaged with the transmission driven teeth 12, and the driven teeth 12 drive the screw to rotate.

[0027] There are two screw rods, namely t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com