Method and device for preparing high-silicon silicon steel thin strip under low-intensity magnetic field

A low-strength, high-silicon technology, applied in electrolytic coatings, coatings, etc., can solve the problems of inability to provide sufficient silicon sources for low-silicon substrates, limitations, poor uniformity of silicon distribution, etc., to achieve stable and controllable production processes and original structure. The effect of small impact and avoiding processing difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1) Preparation of modified silicon-iron particles: The pure silicon powder with a particle size range of 0-10 μm is first added to the ferrous solution in a reducing environment for electroless reduction, so that the surface of the silicon particles is coated with a layer of pure Iron layer, to obtain modified silicon-iron particles, compared with pure silicon particles, the magnetic susceptibility and conductivity of the particles are significantly improved. Then it is filtered and dried in a vacuum environment for later use.

[0040] 2) Preparation of iron reduction solution: Add PAA polymer surfactant and deionized water with a concentration of 20wt% to deionized water in a ratio of 1:4 to 10, and add wetting agent (sodium dodecyl sulfamate) 0.2g / L, dispersant (hexadecyltrimethylammonium bromide) 5g / L, catalyst activator (palladium chloride) 2g / L, add silicon particles 100-500g / L, stir vigorously in water bath for 60min , then add 10-50g / L NaBH4 reducing agent, add ...

Embodiment 2

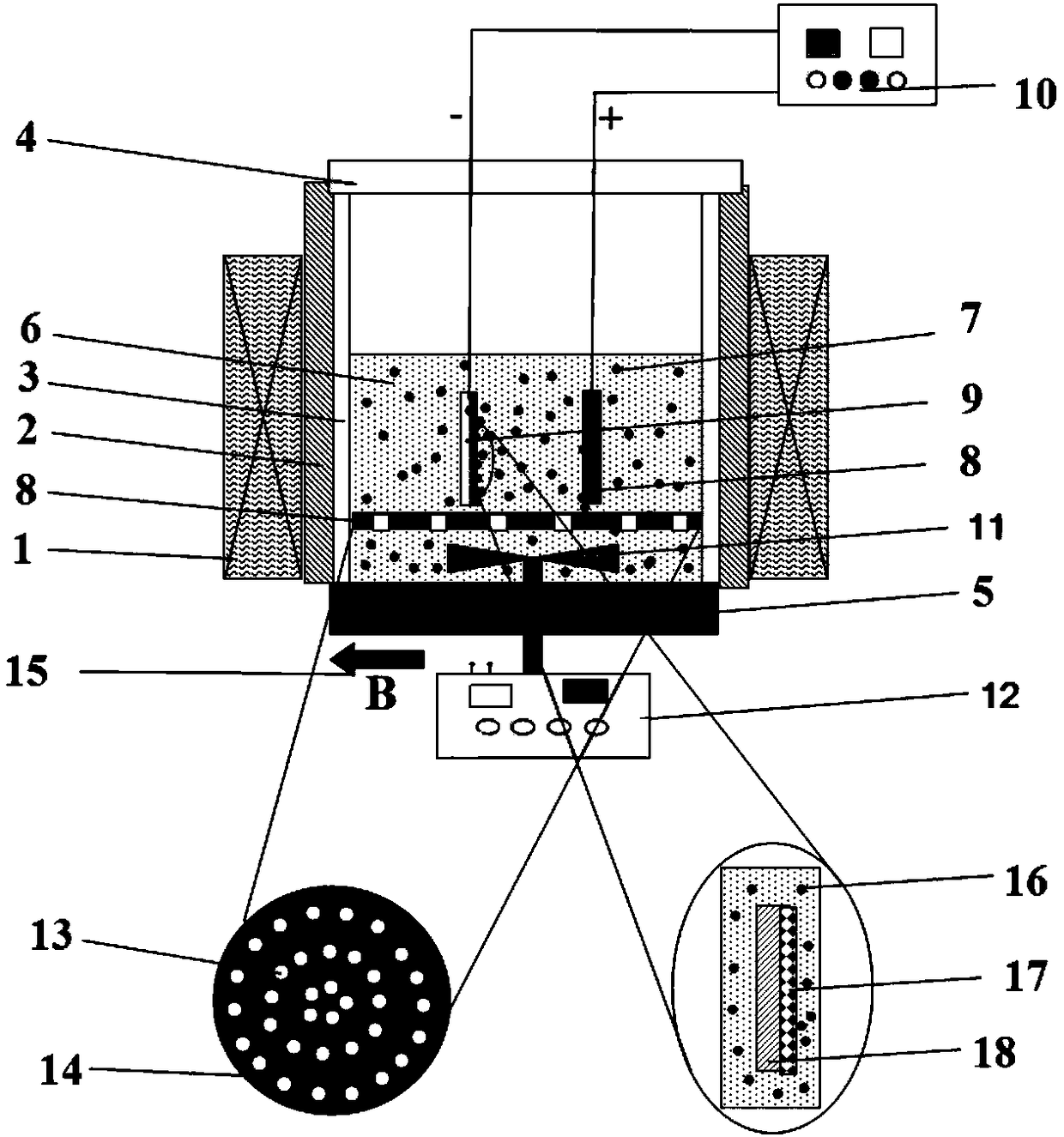

[0046] see figure 1 , the device for preparing high-silicon steel strips under a low-intensity magnetic field is applied to the above method, including a constant magnetic field generator 1, a protection device 2, an electroplating tank 3, an electroplating tank cover plate 4, a polytetrafluoroethylene bottom 5, and an electroplating solution 6 , modified silicon-iron particles 7, pure iron sheet anode 8, low silicon steel strip cathode 9, pulse power supply 10, mechanical stirring paddle 11, mechanical stirring control device 12, grid baffle 14 with mesh 13, etc. The temperature-resistant electroplating tank 3 is placed on the polytetrafluoroethylene base plate 5, and the periphery is successively the electroplating tank 3, the protective material 2 and the constant magnetic field generator 1 from the inside to the outside; the electroplating tank 3 contains the electroplating solution 6 And modified silicon-iron particles 7, the inner bottom is provided with a mechanical sti...

Embodiment 3

[0048] A method for preparing high-silicon silicon steel strips under a low-intensity magnetic field. The specific operation process of this embodiment is as follows:

[0049] Filling the electroplating solution 6 with a peak particle size of 2 μm and plating a 0.1-0.5um iron layer on the surface of the silicon particles to obtain modified silicon-iron particles 7 is placed in a temperature-resistant electroplating tank 3 with a capacity of 50 L. The ingredients are: alcohol as solvent, 0.5mol / L Na2SO4, 0.90mol / L FeSO4, 0.15mol / L FeCl2, 0.43mol / LNH4Cl, adding 20g / L modified silicon-iron particles 7. The electroplating tank 3 is provided with a pure iron sheet anode 8 and a thin strip cathode 9 of low-silicon silicon steel with a silicon content of 3wt% Si. At the same time, in order to ensure that the modified silicon-iron particles 7 in the electroplating solution 6 are evenly distributed, a mechanical stirring paddle 11 and a mechanical stirring control device 12 are used to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com