Technology for anti-buckling and reinforcing metal structure by adopting fiber-reinforced composite

A technology for strengthening components and filling materials, which is applied in the field of buckling-resistant and reinforced metal structures, can solve problems such as difficulty in meeting construction and use requirements, lack of reinforcement methods, and inconvenient transportation, and achieve significant bearing capacity, flexible reinforcement methods, and corrosion resistance. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The metal components subjected to axial compression and compression bending are usually controlled by buckling capacity, that is, the slender components will be destabilized and destroyed under the action of a lower load, and the bearing capacity will be lost before yielding, and the material strength will not be fully utilized. . When the service load of the structure increases or the safety level requirements increase, the buckling resistance reinforcement can be used to increase the instability bearing capacity of the component, so as to achieve the purpose of reinforcement.

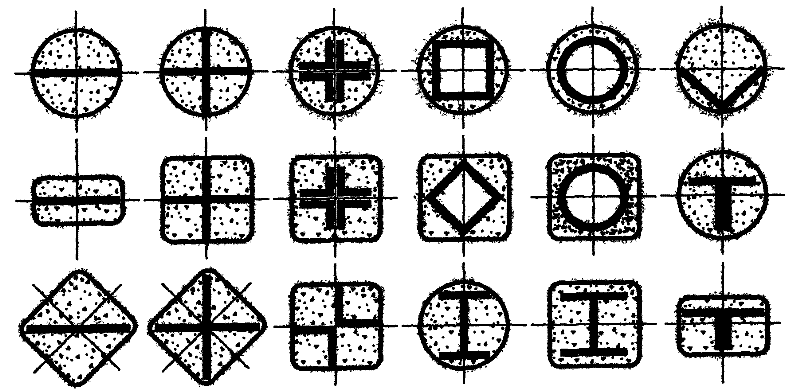

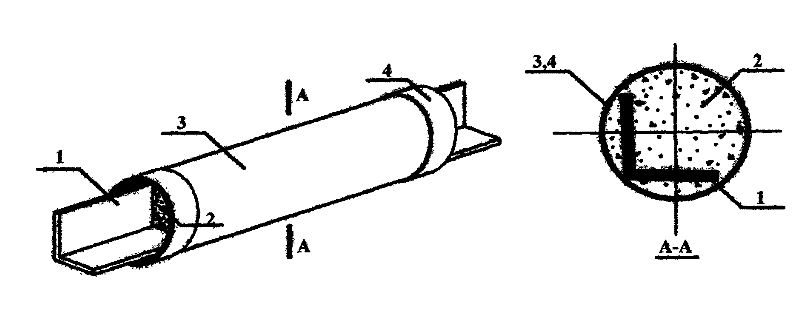

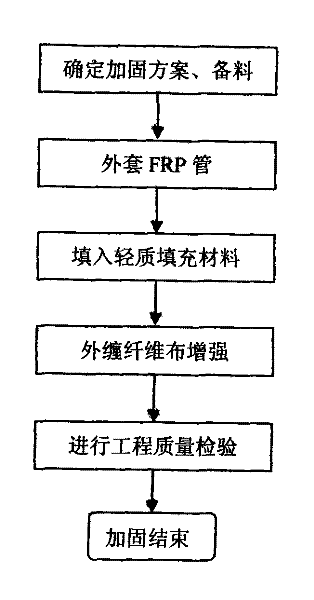

[0036] In the present invention, FRP and lightweight filling materials are used to realize buckling-resistant reinforcement, and there are three types of structures.

[0037] (1) Use solid lightweight materials, such as bamboo, wood, polyurethane foam, etc. to wrap around the reinforced member to form a solid section, such as round, oval, square, etc.; then use FRP profiles to cover the filling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com