Bi-directinoal valve seal mechanism

A valve disc, valve technology, applied in the direction of lift valve, valve device, mechanical equipment, etc., can solve the problem of unsatisfactory sealing, and achieve the effect of good anti-leakage performance and large protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

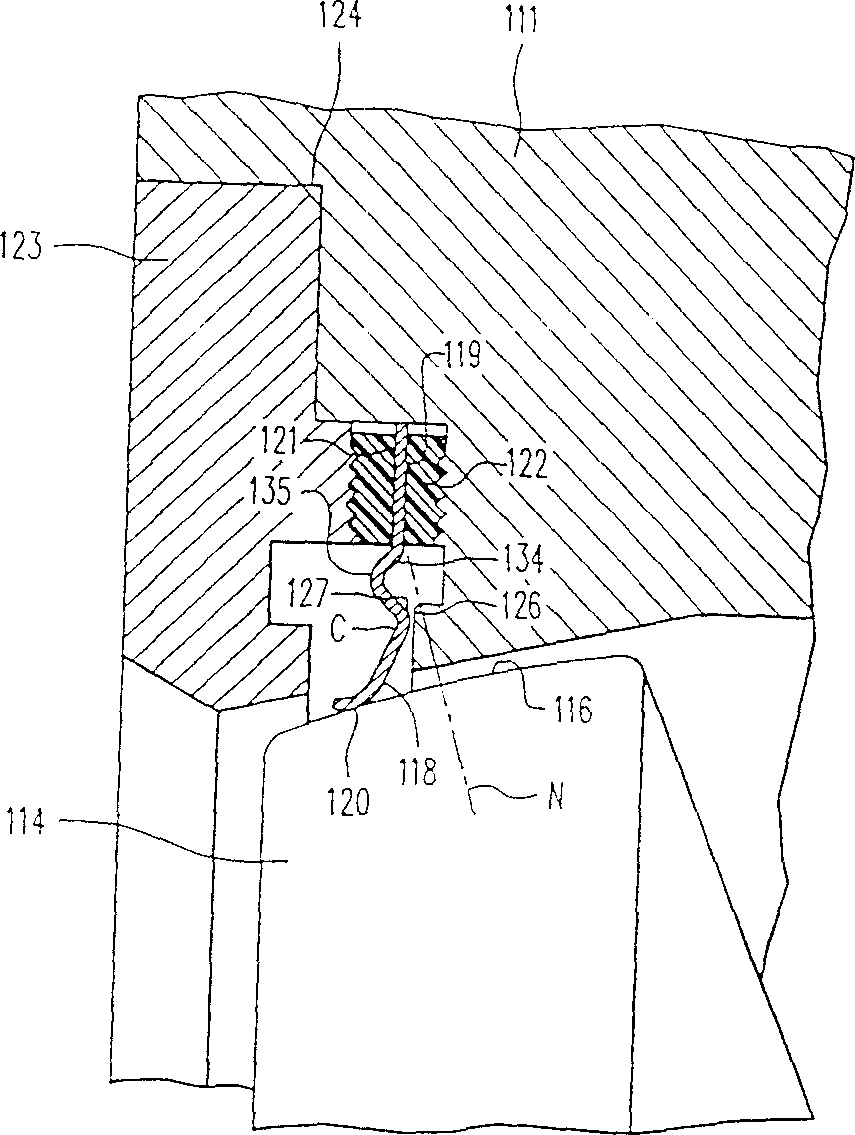

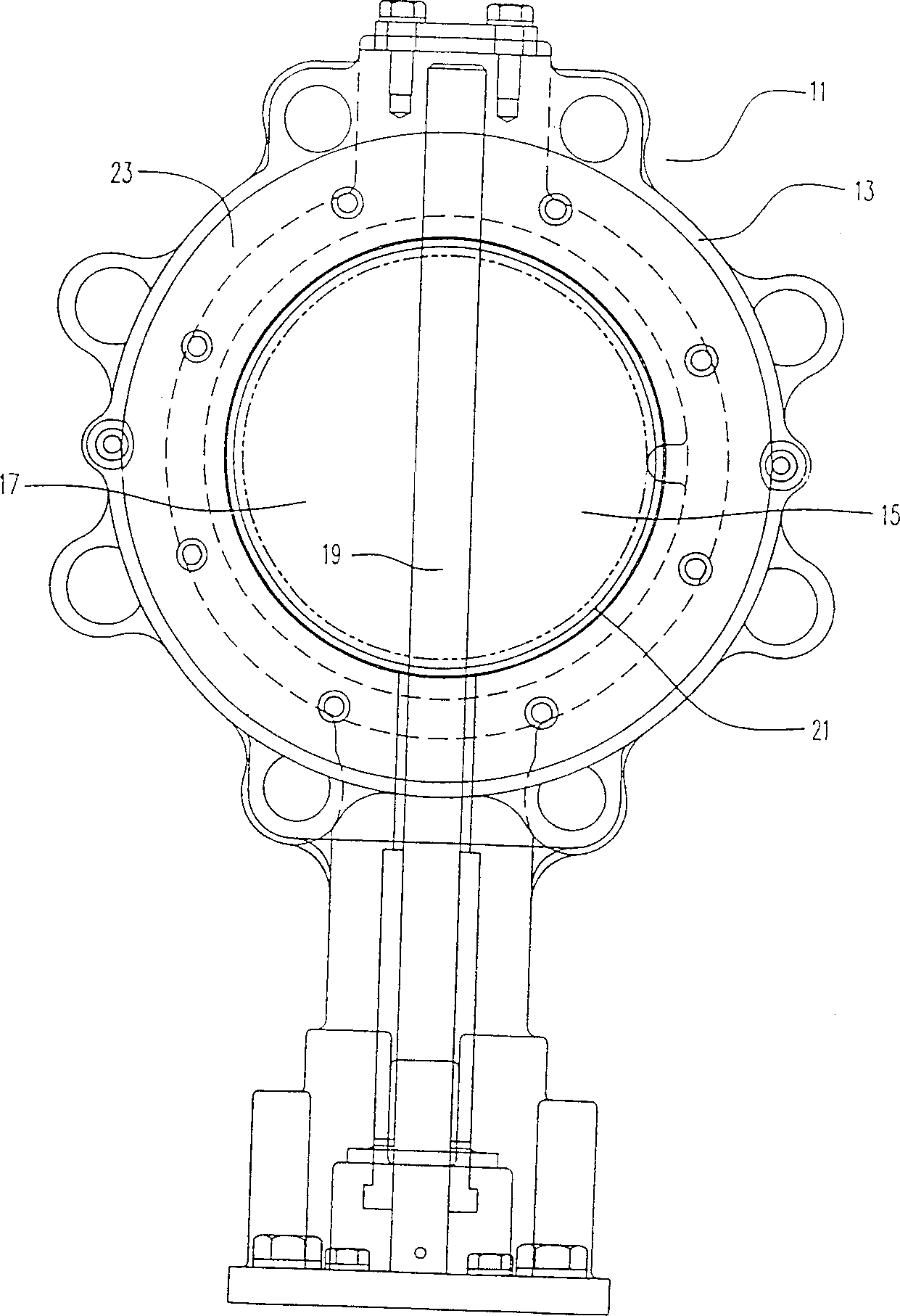

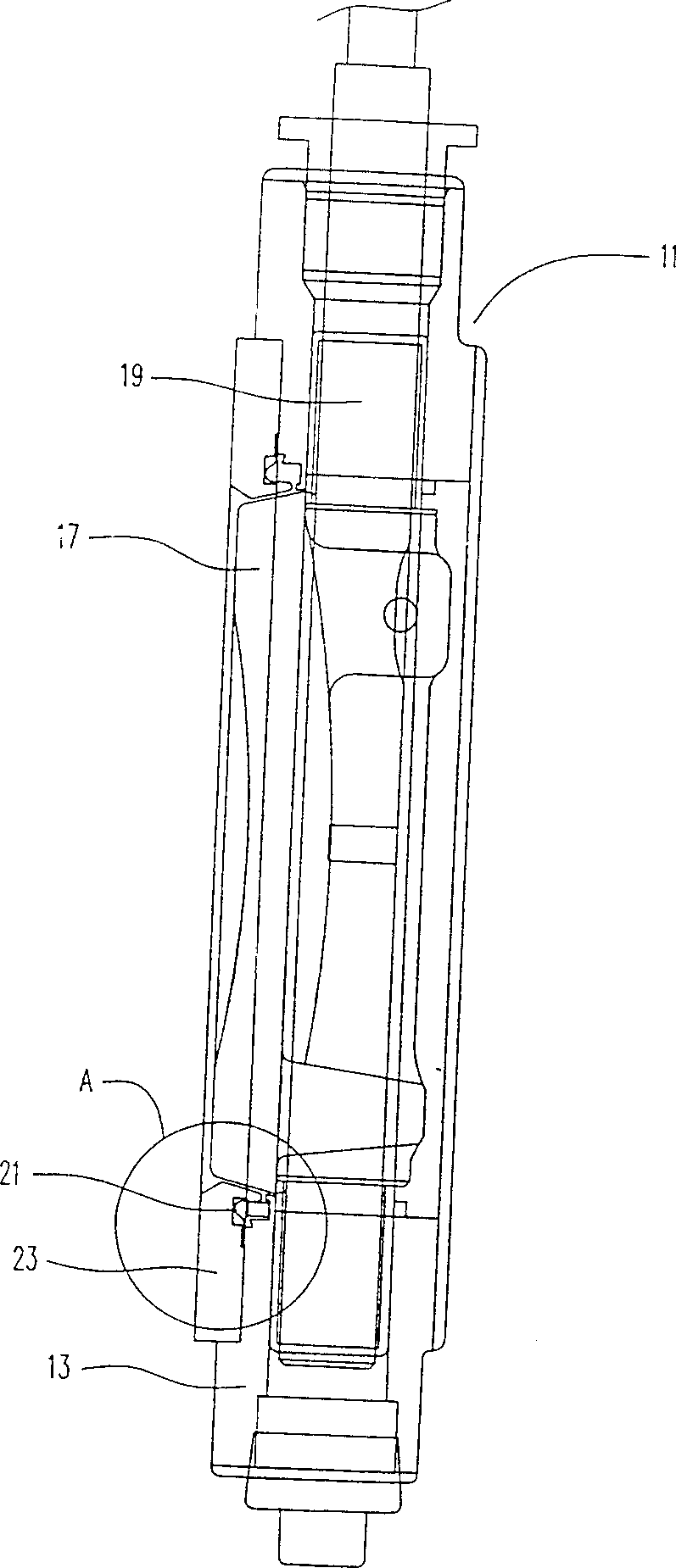

[0026] Such as figure 2 with 3 As shown, the butterfly valve 1 as a preferred embodiment includes a valve body 13 having a central pipe hole 15 through which gaseous or liquid fluid can pass. The spherical valve disc 17 is mounted on the shaft 19 so that it is at least partially located in the hole 15. The valve disc 17 is not a sphere; the term "spherical shape" is used in valve technology to refer to a valve disc 17 that is shaped like a segment or part of a sphere. In this way, its outer edge can form a sphere in space. This can be from Figure 7-9 Clearly seen in. Such as Figure 7 with 8 As shown, the center line of the sphere is located at the center of the shaft and the center of the valve disc from top to bottom. The radius of the sphere R is the radius of the sphere and the radius of the sealing surface ( Figure 7-9 The valve body is not shown). Therefore, generally speaking, the outer circumference of one circular disc surface is larger than the outer circumference of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com