Stubble-cleaning deep-loosening ridger

A technology of ridging machine and subsoiling, which is applied in the field of agricultural machinery, can solve the problems of straw blockage, the inability to realize the distance of subsoiling ridges and ridges, and the difficulty of realizing the height and width of ridges, so as to prevent straw blockage, Good for crop growth and stubble removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

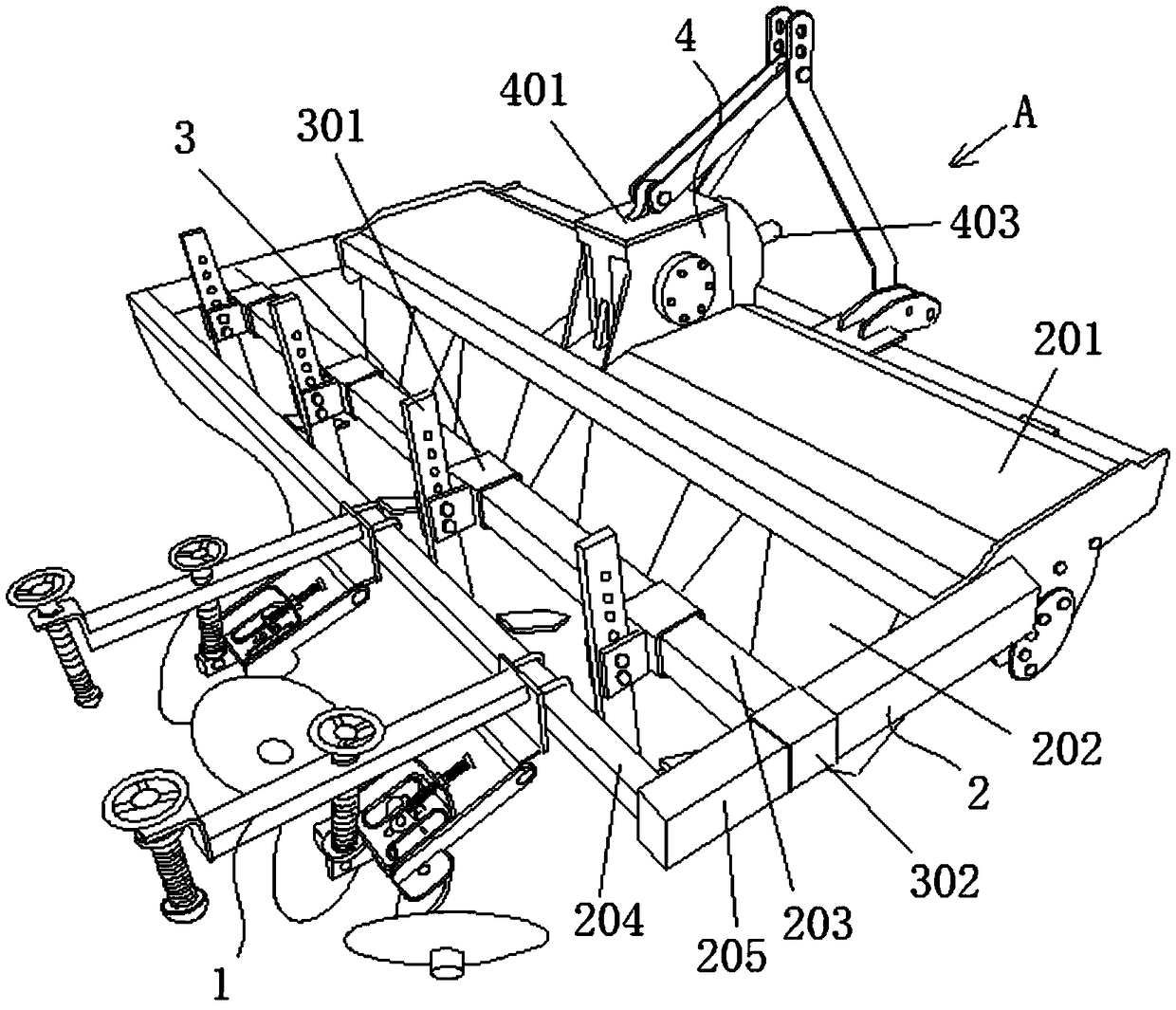

[0029] like Figure 1-10 Shown, the present invention comprises frame 2, stubble removal system 4, subsoiling shovel 3 and ridging device 1, and frame 2 front portion is provided with stubble removal system 4, is provided with subsoiling installation beam 203 at frame 2 middle part, and all The subsoiling installation beam 203 is provided with a plurality of subsoiling shovels 3 , and the rear end of the frame 2 is provided with a ridging installation beam 204 , and the ridging installation beam 204 is provided with a plurality of ridging devices 1 .

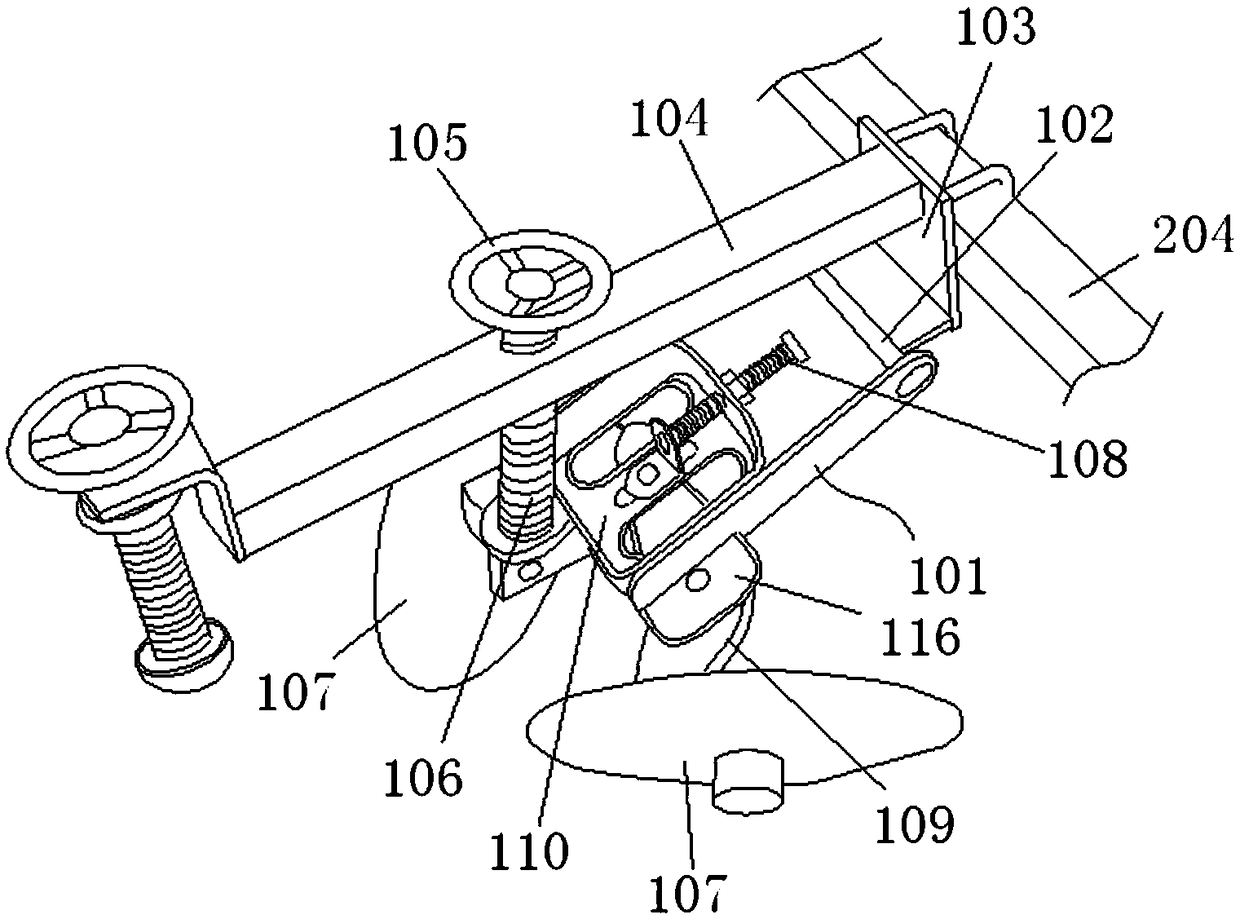

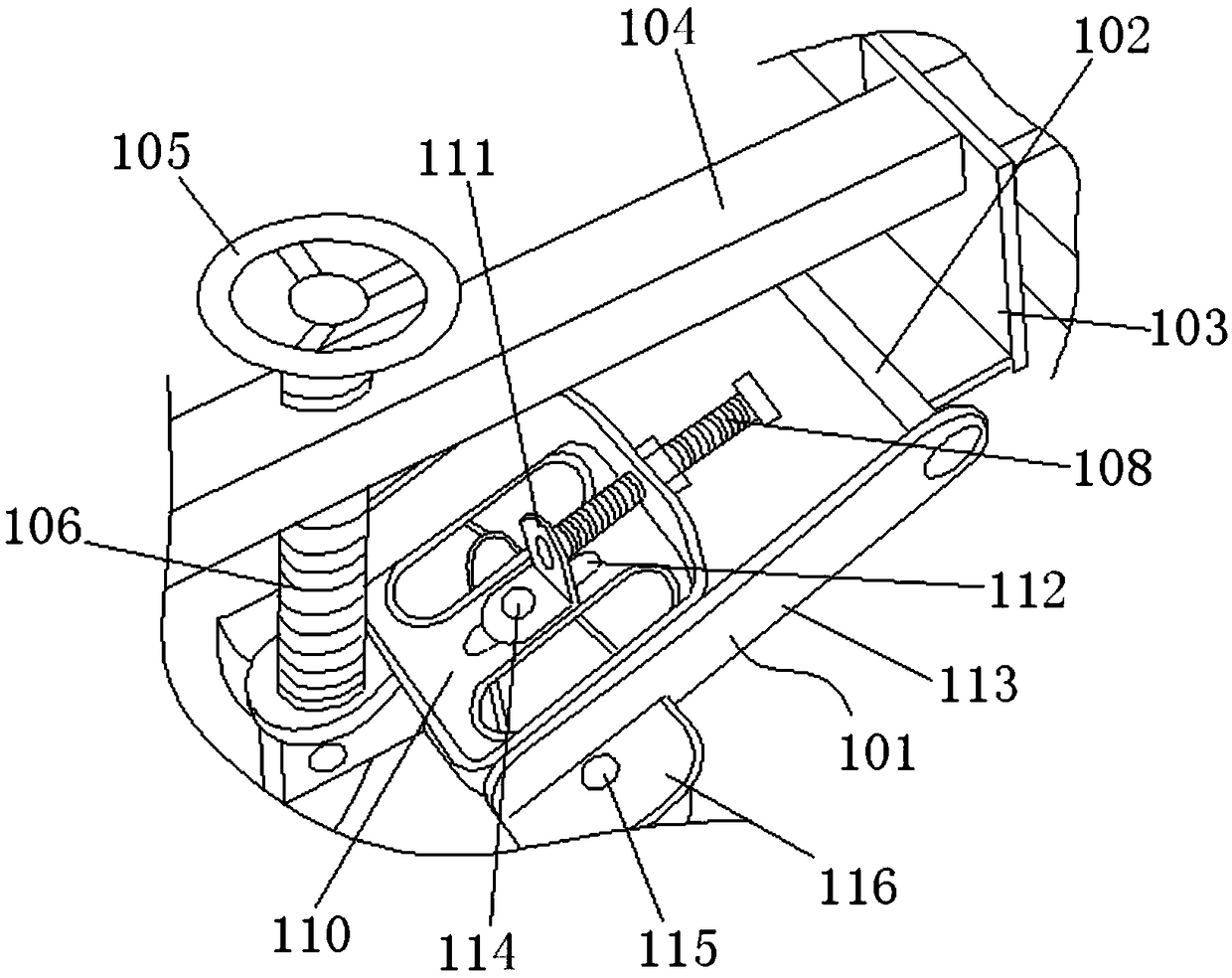

[0030] like Figure 2~4 As shown, the ridging device 1 includes a mounting frame 101, a ridging fixing seat 103, a wheel shaft, a hand wheel 105, a ridging device connecting plate 109 and a ridging disc 107, and the ridging fixing seat 103 is located on the ridging installation. On the beam 204, and the ridge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com