A pipeline electrostatic spraying process

A technology of electrostatic spraying and electrostatic spraying gun, which is applied in the direction of electrostatic spraying device, liquid spraying equipment, coating, etc. It can solve the problems of coating pollution on the inner wall of the pipeline, the reduction of the protective effect of the coating on the pipeline, and the contamination of the inner wall of the pipeline, so as to improve the protection Effect, heating method is convenient, and the effect of improving painting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

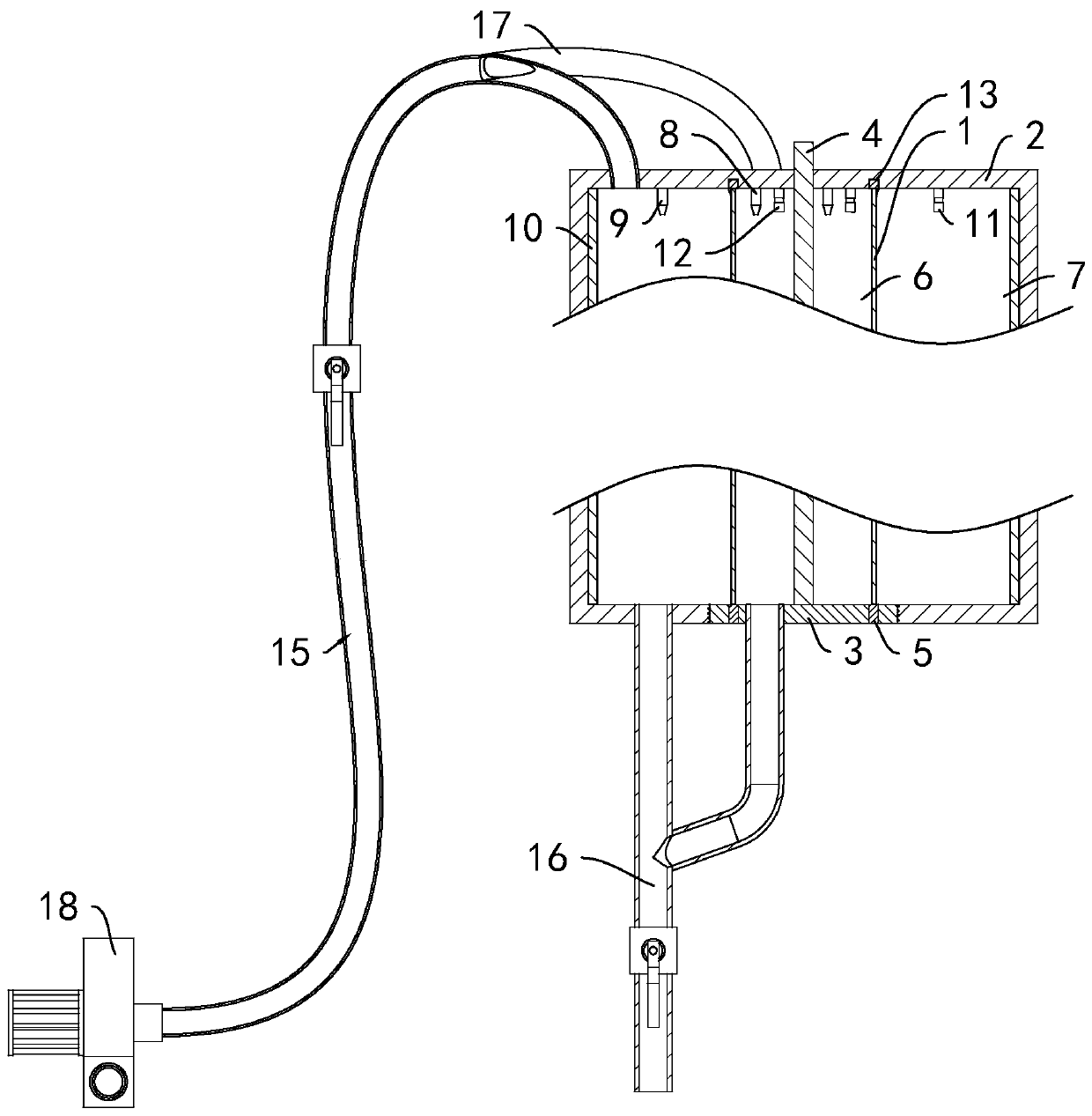

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0034] A pipeline electrostatic spraying process, comprising the following steps:

[0035] Step S1 : pretreatment, using a sandblasting machine to perform sandblasting cleaning on the inner wall of the pipeline 1, and then performing sandblasting cleaning on the outer wall of the pipeline 1. The impact angle between the abrasive and the contact surface of the pipe 1 is 5°~10°, and the highly moving abrasive is used to impact the pipe 1, so as to remove the rust and sundries on the surface of the pipe 1.

[0036] Step S2: Install pipeline 1, such as figure 1 As shown, open the lower cover 3 at the lower end of the painting tooling 2, then place the pipeline 1 in the painting tooling 2, and the upper end of the pipeline 1 is in contact with the second conductive ring 13 at the upper end of the painting tooling 2. Utilize the lower cover 3 to close the opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com