Special extension platform for cutting thick plate by cooperating with IK-WEASEL cutting machine

A technology of extending platform and cutting machine, applied in shearing device, accessories of shearing machine, metal processing equipment, etc., can solve the problems of high labor intensity of employees, difficulty in ensuring cutting accuracy, and inability to guarantee yellow wolf cutting machine, etc. The effect of reducing labor intensity and ensuring machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings and the embodiments.

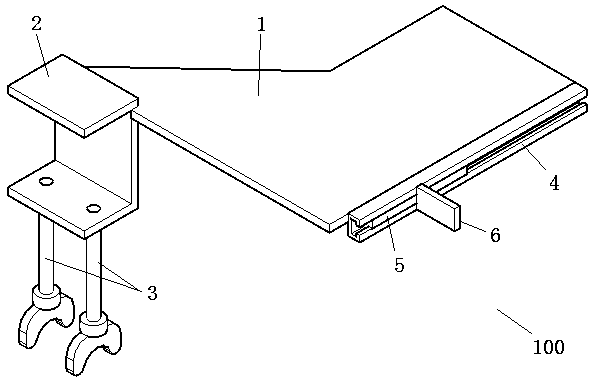

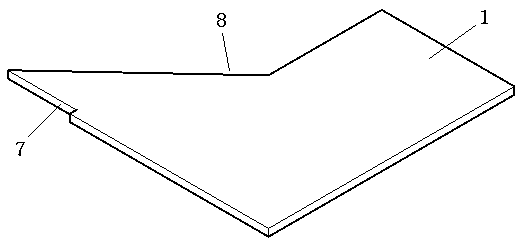

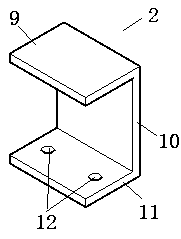

[0020] Such as Figure 1 to 4 As shown, a special extension platform for cutting thick plates with a yellow wolf cutting machine. The extension platform 100 includes a platform plate 1, a U-shaped fixed slot 2, a sliding groove 4, and a slider 5. The left end of the platform plate 1 is provided with a A right-angle trapezoidal gap 8, a rectangular installation slot 7 is provided on the left side of the front end of the platform board 1, and the fixed slot 2 is fixed to the rectangular installation slot 7 of the platform board 1, and the bottom of the fixed slot 2 is provided with two screw holes 12 , Each screw hole is screwed with a butterfly bolt 3, the sliding groove 4 is fixed to the right end of the platform plate 1, and the notch of the sliding groove 4 faces the right, and the front end of the sliding groove 4 is away from the front end o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap