Intelligent rail combining device

An intelligent, driving device technology, applied in transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of many rail lines, large projects, increase system construction costs and post-maintenance costs, etc., to reduce costs and save costs. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1. This system can be used in many automated production fields, such as food processing, supermarket fresh food, clothing processing and other fields. This embodiment takes supermarket delivery as an example.

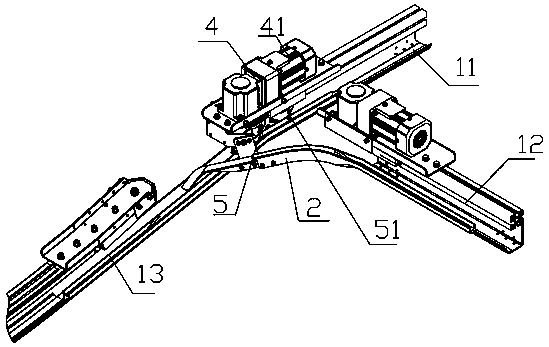

[0029] Such as figure 1 As shown, it includes the main rail and the access rail. Both the access rail and the main rail are transporting goods, and the goods on the access rail are also transferred to the main rail. There is a connection position between the access rail and the main rail. The connection here The location does not mean that there must be a physical physical contact point, but there is a logistics intersection point, and the goods enter the main rail through the intersection point on the access rail.

[0030] In order to facilitate the control, the main rail is also divided into front and rear ends at the junction, such as figure 1 As shown, it is divided into track one 11 and track three 13. In this case, the access track is track two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com