Passive weight reduction mechanism design

A technology of force arm and slider, which is applied in the field of passive weight reduction mechanism design, can solve the problems of difficulty in adjusting more variable requirements, no larger adjustable range, and noise from the motor, achieving low cost and convenient suspension Heavy objects, the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

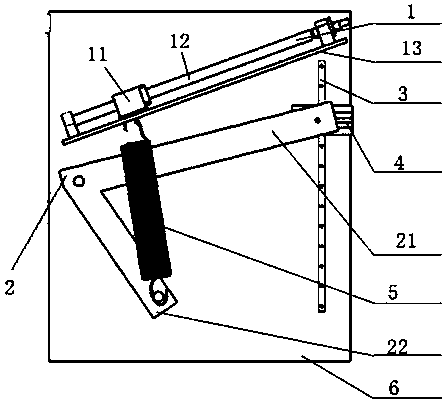

Image

Examples

Embodiment 2

[0023] The general structure is similar to that of Embodiment 1, the difference is that a plurality of spring hooks are set on the slider b11, and a plurality of springs 5 are hooked between the slider b11 and the moment arm 22 at the same time, so as to increase the weight loss of different masses. Heavy adaptability.

Embodiment 3

[0025] The general structure is similar to that of Embodiment 1, the difference is that a manual handle is added to the end of the ball screw 1 to improve the portability and portability of the rotary screw adjustment.

Embodiment 4

[0027] The general structure is similar to that of Embodiment 1, the difference is that the support plate 6 can be hollowed out except for the part where the force is concentrated, which not only saves materials, but also increases the overall appearance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com