Warp knitted elastic fabric imitating pique and preparation method thereof

The technology of pearl mesh cloth and mesh cloth is applied in the field of clothing fabrics, which can solve the problems of poor dimensional stability of fabrics, easy shrinkage and deformation of fabrics, etc., and achieve the effects of beautiful fit, two-way elasticity, excellent dimensional stability, and increased service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The present embodiment provides a kind of warp-knitted elastic fabric imitating the pearl mesh cloth, which is composed of the following mass percentage components: 100s / 2 cotton strands: 16.0%, 70D24F nylon DTY is 70.0%, 40D spandex is 14%, The fabric is made of cotton yarns on the front side to create a simulated single piqué effect or a double piqué effect.

[0042] The preparation method comprises the following steps:

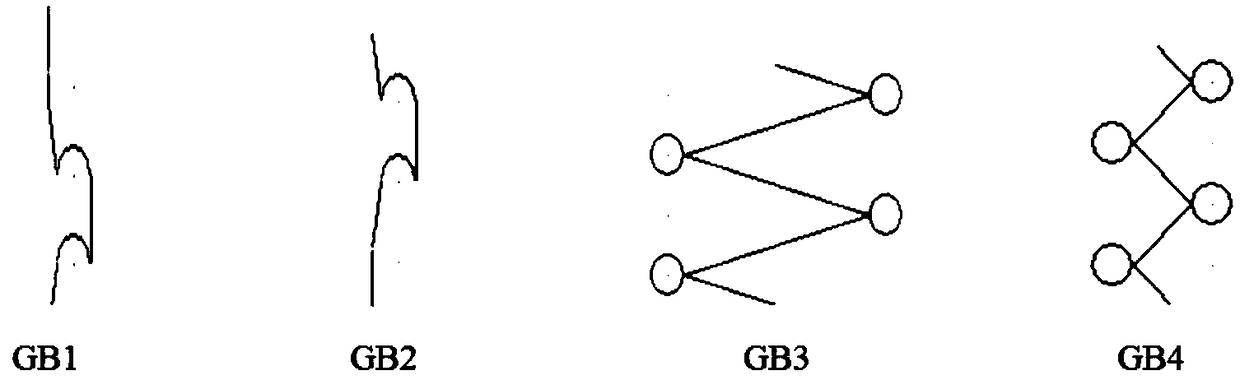

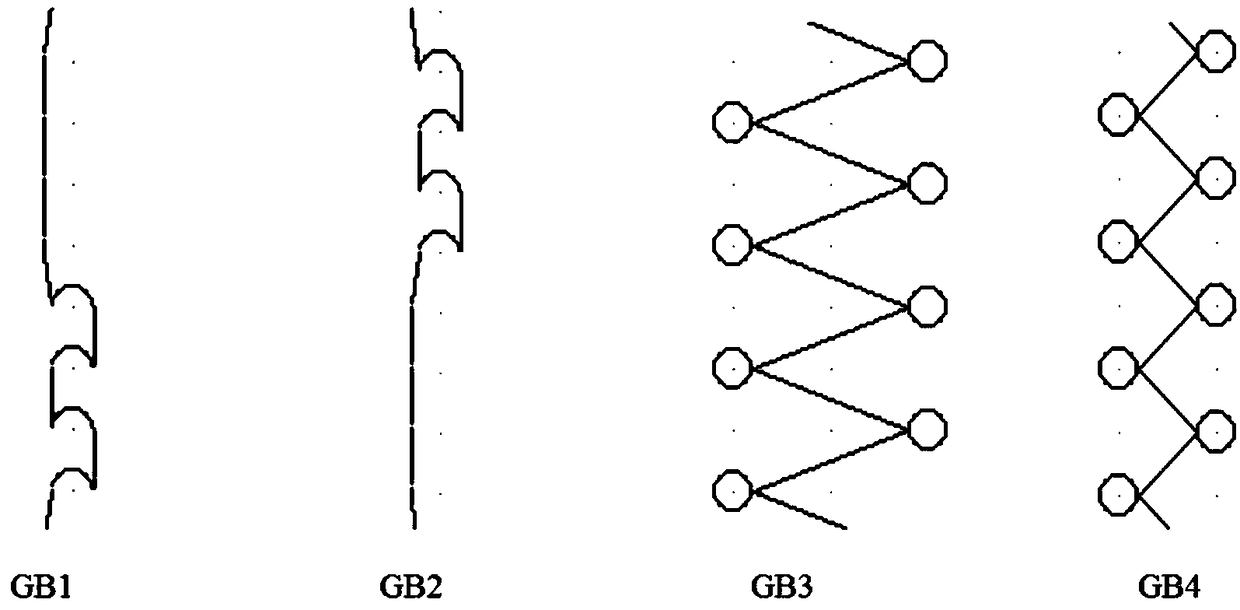

[0043] Single comb structure selection, preparation process, warping, weaving, setting.

[0044] 1. Preparation process

[0045] Choose 50s~120s cotton yarn, choose 40D~70D nylon DTY and 40D~70D spandex cheese;

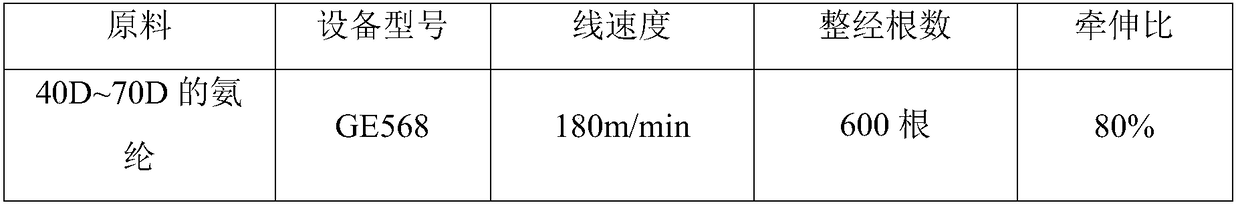

[0046] 2. Warping process

[0047] Temperature and humidity at the warping site: temperature 25±1°C, relative humidity 65±5%, high and stable temperature and humidity are conducive to the stability of cotton yarn twisting and soft surface, avoiding entanglement of cotton yarns, which is beneficial to warp knitting Production of products....

Embodiment 2

[0086] The present embodiment provides a warp-knitted elastic T-shirt fabric that imitates pearl mesh cloth, which is composed of the following mass percentage components: 100s / 2 cotton strands are 30.0%, 70D24F nylon DTY is 51.0%, and 40D spandex is 19.0%. , the fabric wears cotton yarn on the front side to form a single piqué effect or double piqué effect.

[0087] The preparation method comprises the following steps:

[0088] Single comb structure selection, preparation process, warping, weaving, setting.

[0089] 1. Preparation process

[0090] Choose 50s~120s cotton yarn, choose 40D~70D nylon DTY and 40D~70D spandex cheese;

[0091] 2. Warping process

[0092] Temperature and humidity at the warping site: temperature 25±1°C, relative humidity 65±5%, high and stable temperature and humidity are conducive to the stability of cotton yarn twisting and soft surface, avoiding entanglement of cotton yarns, which is beneficial to warp knitting Production of products.

[0093...

Embodiment 3

[0127] The present embodiment provides a warp-knitted elastic T-shirt fabric that imitates pearl mesh cloth, which is composed of the following mass percentage components: 100s / 2 cotton strands are 42.0%, 70D24F nylon DTY is 35.0%, and 40D spandex is 23.0%. , the fabric wears cotton yarn on the front side to form a single piqué effect or double piqué effect.

[0128] The preparation method comprises the following steps:

[0129] Single comb structure selection, preparation process, warping, weaving, setting.

[0130] 1. Preparation process

[0131] Choose 50s~120s cotton yarn, choose 40D~70D nylon DTY and 40D~70D spandex cheese;

[0132] 2. Warping process

[0133] Temperature and humidity at the warping site: temperature 25±1°C, relative humidity 65±5%, high and stable temperature and humidity are conducive to the stability of cotton yarn twisting and soft surface, avoiding entanglement of cotton yarns, which is beneficial to warp knitting Production of products.

[0134...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com