Suction nozzle body for cleaning sweeper truck double type high pressure water spray rod mechanism

A high-pressure water spraying and sweeping car washing technology, which is applied in the field of sweeping cars, can solve the problems of energy waste, secondary pollution, and low cleaning efficiency, and achieve the effects of improving cleaning effect, maintaining sealing performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

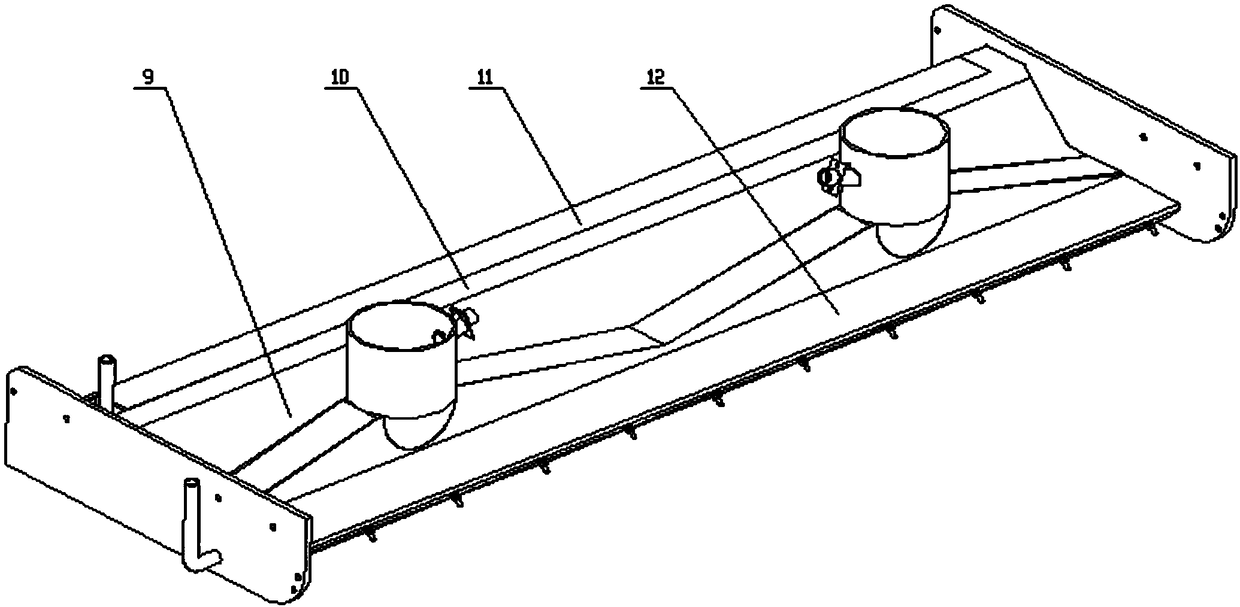

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

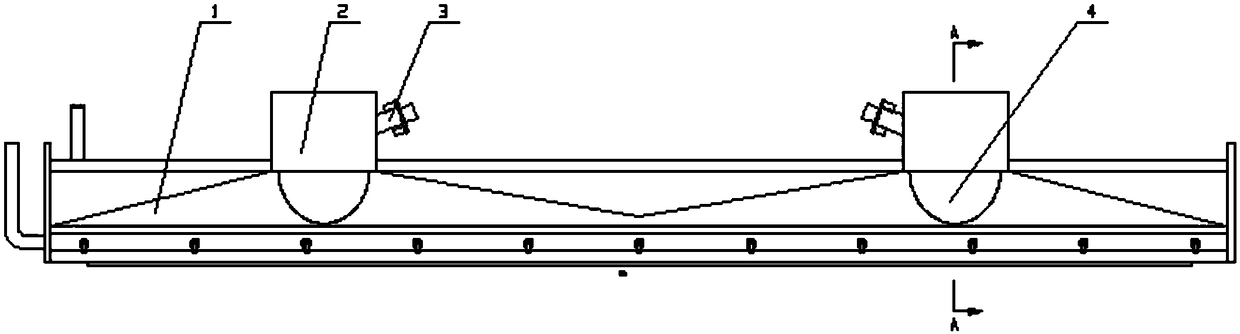

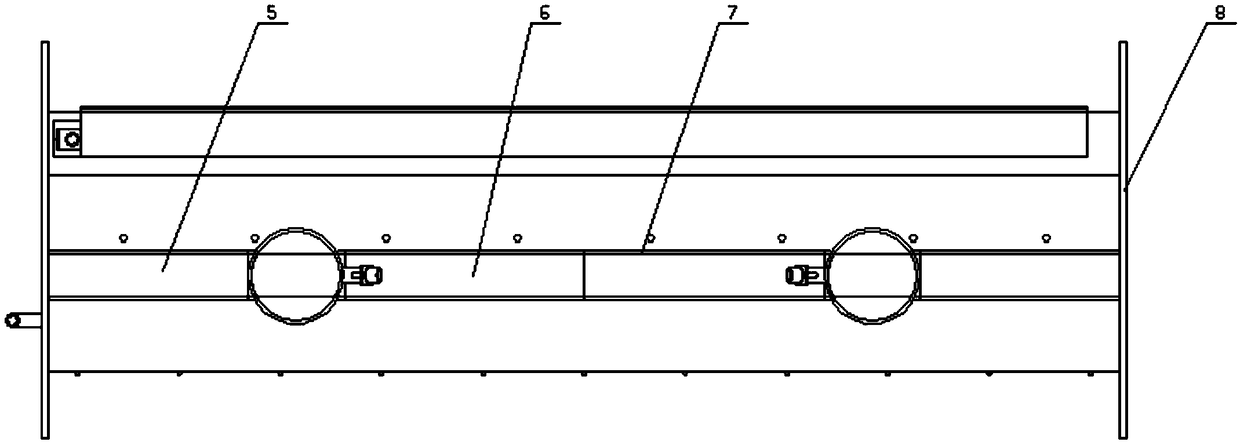

[0028] refer to Figure 1 to Figure 5 As shown, the nozzle body of the double-type high-pressure water spray bar mechanism of the washing and sweeping car in an embodiment provided by the present invention includes a nozzle cavity, and it also includes a front rubber plate 14, a rubber plate 21 at the rear of the water spray chamber and The lower block of the suction nozzle, the suction nozzle cavity is provided with a plurality of suction ports along the length direction, the front rubber plate 14 and the rear rubber plate 21 of the water spray chamber are respectively arranged at the front end and the rear end of the suction nozzle cavity, and the suction nozzle lower block The block is arranged at the bottom of the suction nozzle cavity, and the lower stopper of the suction nozzle is arranged between the front rubber plate 14 and the rear rubber pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com