Construction method for open dredging and underground excavation integral lining

A construction method and integrated technology, applied in wellbore lining, tunnel lining, artificial island, etc., to achieve the effect of mature and reliable technology, saving road occupation time, and avoiding uncontrollable settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

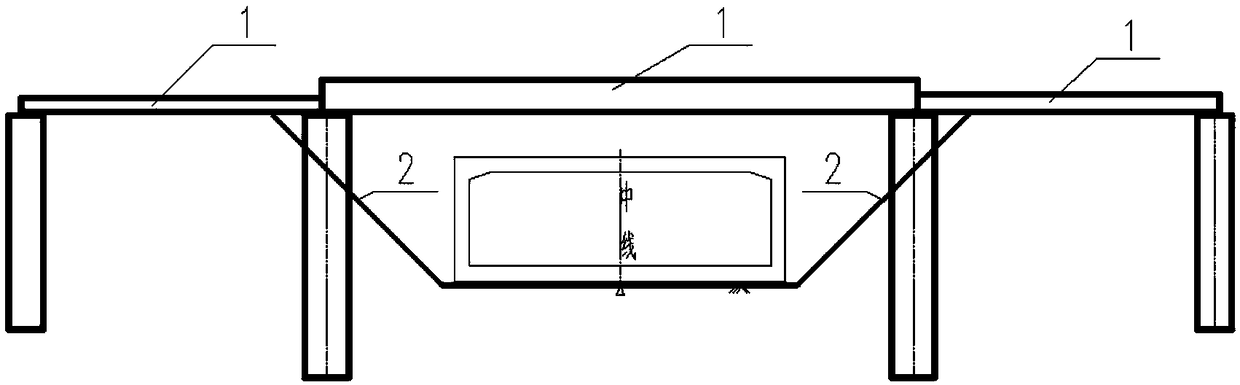

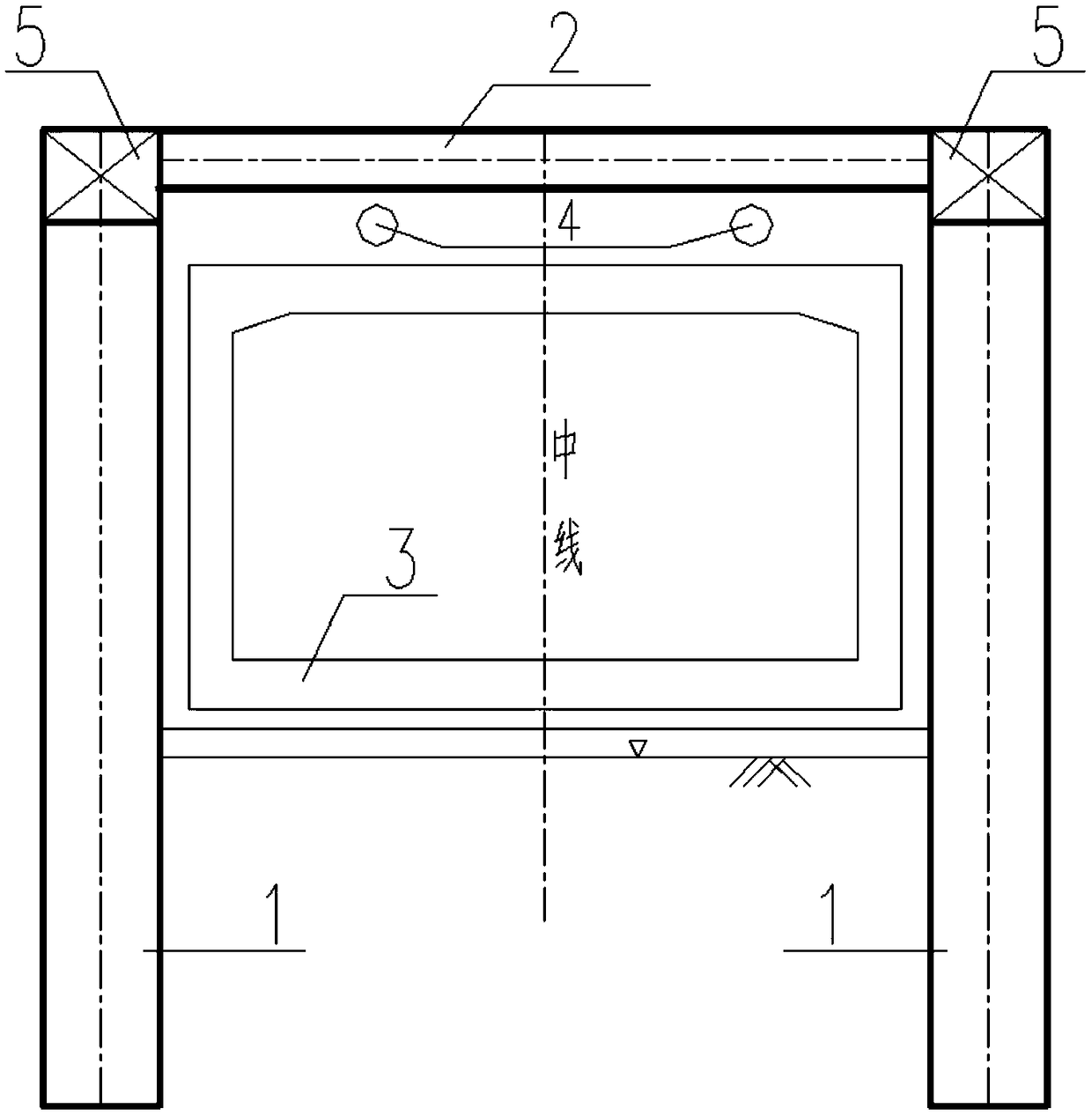

[0029] Example 1, such as figure 2 shown.

[0030] The construction method of the present invention for integral lining with open cut and concealed, comprises the following steps:

[0031] S1. Temporarily suspend the use of part of the railway track or occupy the road by framing, and use quick pile construction for vertical enclosure 1;

[0032] S2, perform roof support 2, restore the occupied road or the disabled railway track;

[0033] S3, looping steps S1-S2 until fully recovering roads or railway tracks;

[0034] S4. From the lateral sides of the road or the railway track, excavate the earthwork by digging into the hole;

[0035] S5. Level the tunnel enclosure and tunnel roof surface after excavation;

[0036] S6, make the tunnel waterproof and bind the steel bars, and make the main structure 3;

[0037] S7. Backfill the earth and rock between the main structure 3 and the top plate support 2, and press the grout after the backfilling is completed by reserving the gro...

Embodiment 2

[0040] In step S1, the rapid pile formation includes processes such as rotary drilling, pile formation, and prefabricated pile hoisting.

Embodiment 3

[0042] In step S1, the vertical enclosure 1 is also provided with a water-stop curtain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com