Novel railway multifunctional operating vehicle

A multi-functional, working vehicle technology, applied in the direction of railway car body parts, transport passenger cars, electric vehicles, etc., can solve the problems that the maintenance section cannot be equipped with multiple equipment, the installation takes up a lot of space, and delays in opening time to improve flexibility. and adaptability, small installation space and comprehensive operation content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

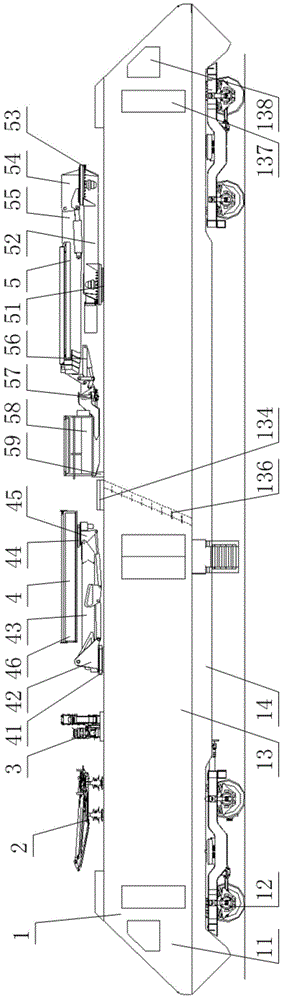

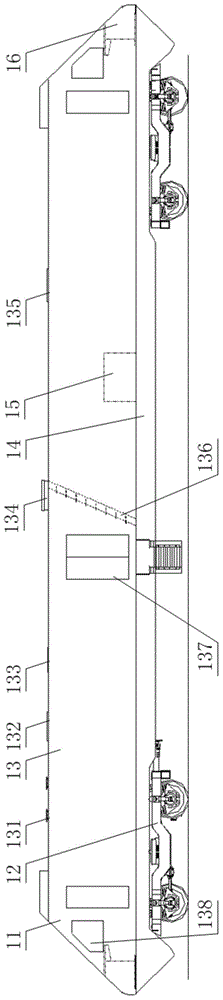

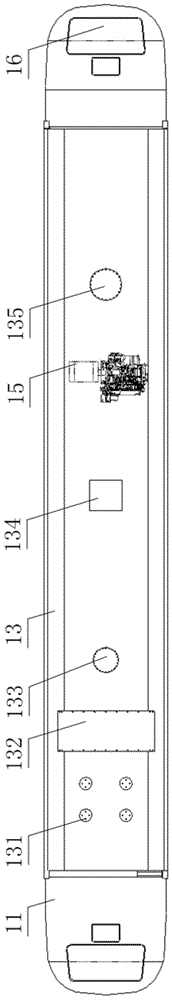

[0068] Below in conjunction with accompanying drawing of description, the present invention will be further described.

[0069] Such as Figure 1 to Figure 12 As shown, a new type of railway multifunctional operation vehicle includes a locomotive 1, a pantograph 2, a wire pulling device 3, a rotary lifting platform 4, and an aerial work bucket 5.

[0070] The locomotive 1 is sequentially installed with a pantograph 2 , a wire pulling device 3 , a rotary lifting platform 4 , and an aerial work bucket 5 along the length direction of the locomotive 1 from a certain end of its top. Each implement is positioned at the middle position of locomotive 1 top width direction. A sufficient safety distance is reserved between each machine tool for the machine tool to be deployed and the personnel to pass through. The pantograph 2 is installed on the top of the locomotive 1 through bolts, and is an electrical device for the locomotive 1 to obtain electric energy from the catenary. The wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com