A Construction Method of Excavating and Concealing Integral Lining

A construction method and open-cut technology, applied in wellbore lining, tunnel lining, artificial island, etc., to avoid difficult control of settlement, save road occupation time, and mature and reliable technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

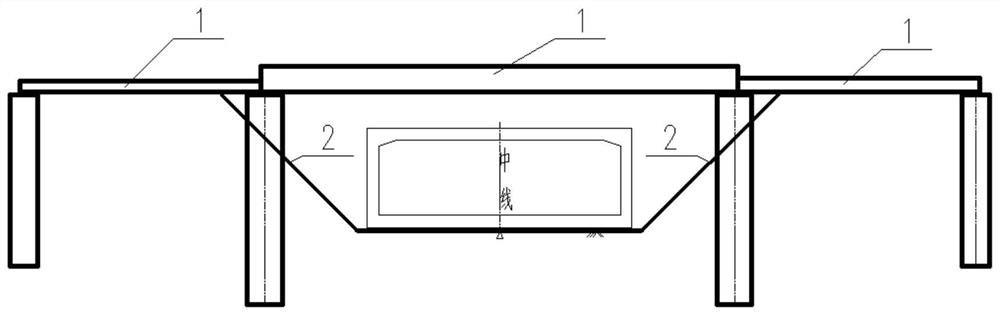

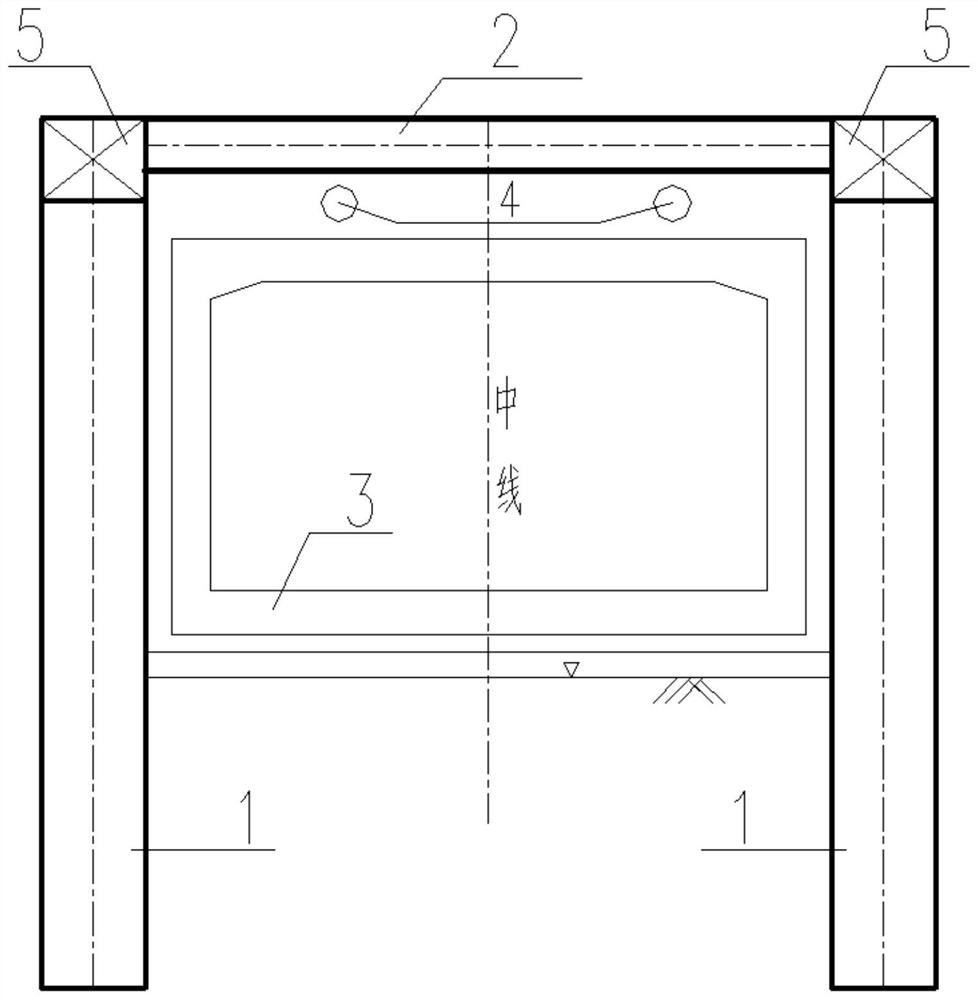

[0029] Example 1, such as figure 2 shown.

[0030] The construction method of the present invention for integral lining with open cut and concealed, comprises the following steps:

[0031] S1. Temporarily suspend the use of part of the railway track or occupy the road by framing, and use quick pile construction for vertical enclosure 1;

[0032] S2, perform roof support 2, restore the occupied road or the disabled railway track;

[0033] S3, looping steps S1-S2 until fully recovering roads or railway tracks;

[0034] S4. From the lateral sides of the road or the railway track, excavate the earthwork by digging into the hole;

[0035] S5. Level the tunnel enclosure and tunnel roof surface after excavation;

[0036] S6, make the tunnel waterproof and bind the steel bars, and make the main structure 3;

[0037] S7. Backfill the earth and rock between the main structure 3 and the top plate support 2, and press the grout after the backfilling is completed by reserving the gro...

Embodiment 2

[0040] In step S1, the rapid pile formation includes processes such as rotary drilling, pile formation, and prefabricated pile hoisting.

Embodiment 3

[0042] In step S1, the vertical enclosure 1 is also provided with a water-stop curtain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com