Backfilling construction method for slotted buried pipe foundation trench by adopting self-compacting backfill material

A construction method and backfilling technology, which is applied in filling, foundation structure engineering, construction, etc., can solve the problems of large post-construction settlement, large human factors, and difficulty in controlling the density of backfilling, so as to reduce road occupation time, The effect of speeding up the construction progress and solving the tension of sand sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

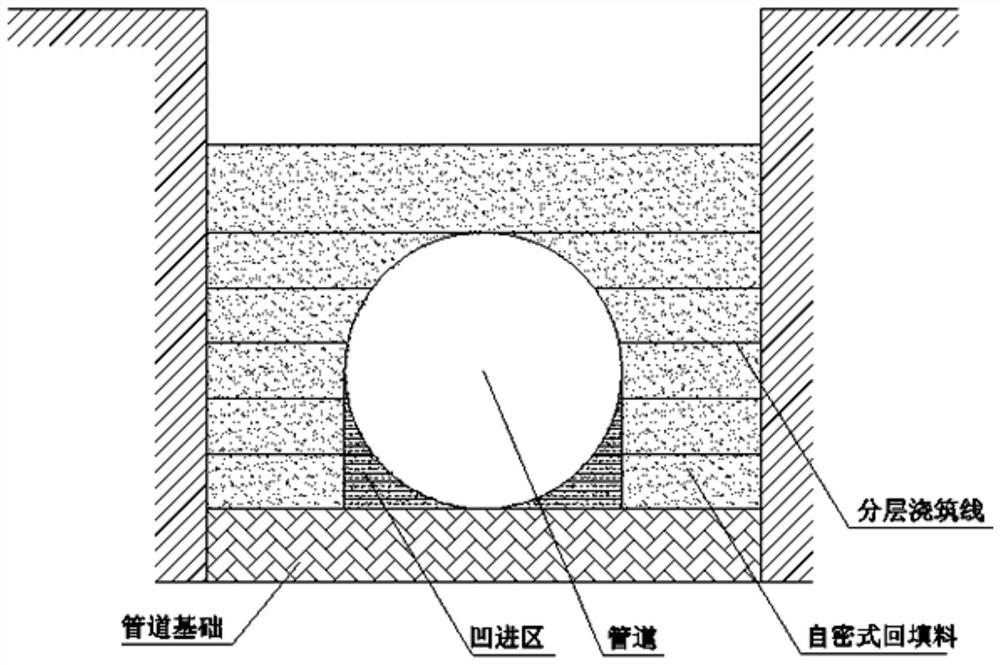

[0024] Such as figure 1 As shown, a specific embodiment of the construction method for backfilling the foundation groove of the slotted buried pipe adopting self-compacting backfill of the present invention, the steps are as follows:

[0025] Step 1: Pulverize the construction waste aggregate, then add fine-grained soil, curing agent and additives, and then stir to form self-compacting backfill;

[0026] Step 2. The self-compacting backfill formed after the stirring is completed is poured in layers by pumping, so that the buoyancy is less than the weight of the pipeline;

[0027] Step 3. Within 28 days after the pouring is completed, the unconfined compressive strength of the self-compacting backfill is controlled within 1 MPa to 2 MPa.

[0028] The invention adopts flowing self-compacting backfill, and the gaps in the base groove can be completely filled, which solves the problem that the conventional backfill material cannot be mechanically compacted in the recessed area of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com