Gas extracting drilling solid-liquid two-phase hole sealing device and technology

A gas drainage and sealing device technology, which is applied in the direction of gas discharge, safety devices, mining equipment, etc., can solve the problems of sealing holes, drainage drilling, etc., and achieve the effects of convenient and fast fixing, avoiding excessive consumption, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

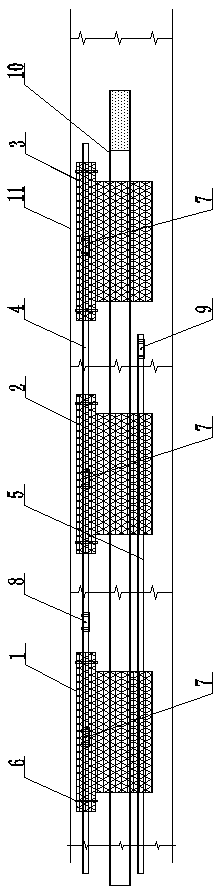

[0034] Such as figure 1 As shown, a gas drainage drilling solid-liquid two-phase hole sealing device of the present invention includes No. 1 bag 1, No. 2 bag 2, No. 3 bag 3, primary grouting pipe 4 and secondary grouting pipe 5. The structures of the No. 1 bag 1 and the No. 2 bag 2 are the same, and the No. 1 bag 1 and the No. 2 bag 2 are provided with the primary grouting pipe 4, the secondary grouting pipe 5 and the gas extraction sleeve respectively. The hole through which the pipe 10 passes; the third bag 3 is provided with a hole for the primary grouting pipe 4 and the gas drainage casing 10 to pass through; the first bag 1, the second bag 2 and the third bag The two ends of 3 are fixedly installed on the primary grouting pipe 4 through the snap ring 6 respectively. When fixing the No. 1 pouch 1, the No. 2 pouch 2 and the No. 3 pouch 3, you are not limited to using the snap ring 6, and you can also use steel wire, hemp rope or strong adhesive tape.

[0035] The primary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com