Telescopic ignition plug

A telescopic and electric nozzle technology, which is applied in the direction of jet propulsion devices, gas turbine devices, machines/engines, etc., can solve the problems that the electric nozzle parts are in high pressure and high temperature working environment, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution created by the present invention is described in detail in conjunction with the accompanying drawings and specific embodiments.

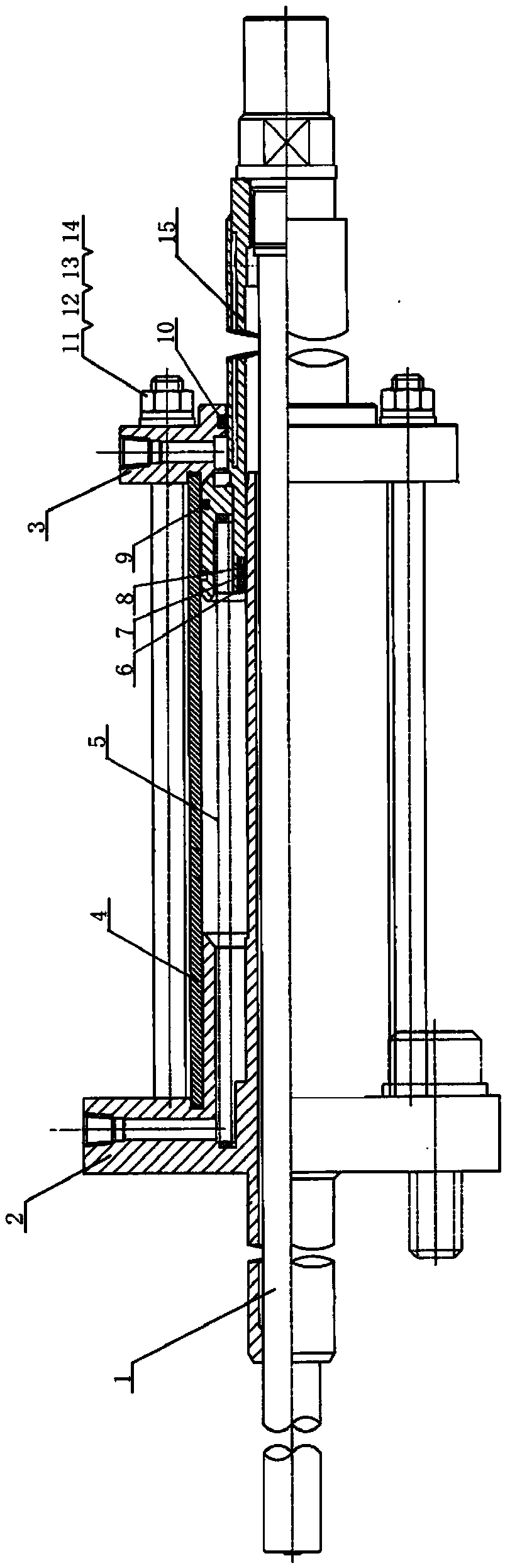

[0014] Such as figure 1 As shown, a retractable ignition nozzle includes a nozzle assembly 1, a front flange 2, a rear flange 3, a cylinder 4, a spring 5, a limit washer 6, a step seal 7, a sealing ring a8, Seal ring b9, seal ring c10, flat washer 11, spring washer 12, nut 13, stud 14 and seal sleeve 15.

[0015] After the nozzle assembly 1 is threaded with the sealing sleeve 15, it is fixed in the cylinder 4 through the front flange 2 and the rear flange 3; the spring 5 is located in the installation groove of the front flange 2 and the rear flange 3 , the front flange 2 and the rear flange 3 are fastened by studs 14, flat washers 11, spring washers 12, and nuts 13; limit washers 6, step seals 7, and sealing ring a8 are placed in the sealing sleeve 15 for sealing The sealing ring b9 is placed in the outer sealing gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com