A single-lever double-stage joint control adjustable hoop-type camera carrier body

A hoop-type camera technology, which is applied in the field of adjustable hoop-type camera bearing frame with single lever and double-cascade control, can solve the problems of cumbersome operation and achieve a stable structure, not easy to damage, effective and safe adjustment results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

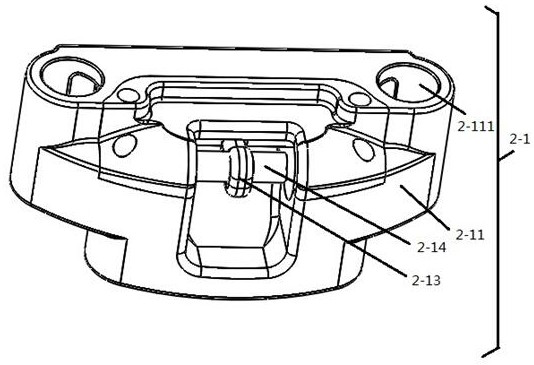

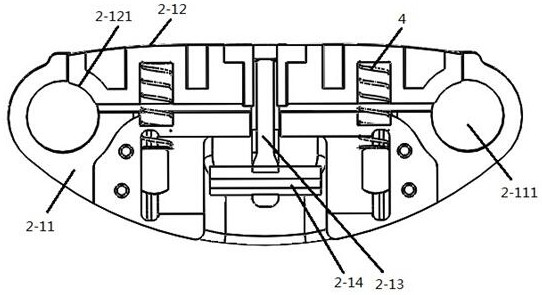

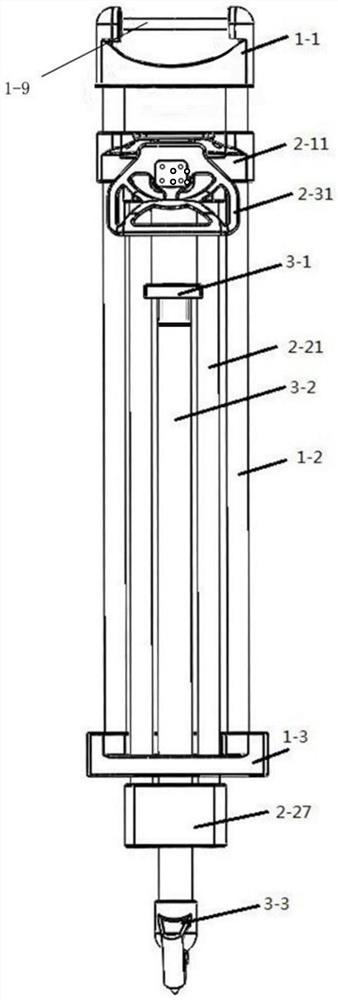

[0064] A single-wrench double-cascade control adjustable hoop-type camera carrier body, including a fixing part 1, a first sliding part 2, and a second sliding part 3; the fixing part 1 includes a fork frame 1-1, and a fixed support rod 1 -2. Slide frame 1-3, base 1-4 is provided above the fork frame 1-1, the middle part of the plane of base 1-4 is a conical surface, and three shaft fixing seats 1-5 are arranged on the side, and the three shafts The outer surface of the holder 1-5 is arc-shaped, and the inside of the arc is provided with shaft mounting grooves, and fixed connection shafts 1-9 are installed in the three shaft mounting grooves, and the two ends of the three fixed connection shafts 1-9 are Connect with ears on both sides of the top of the fork frame 1-1 respectively, the bottom of the center of the base 1-4 is provided with a bowl-shaped bracket 1-6, the center of the bracket 1-6 is provided with a round hole, and the bracket 1-6 is also provided with a Weight re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com