Thermal power unit analog manual station and method

A thermal power unit and manual station technology, applied in simulators, instruments, control/regulation systems, etc., can solve problems such as increased misoperation of operation steps and procedures, complicated operation interface, equipment damage, etc., and achieves stable control and multiple working modes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and application examples in engineering.

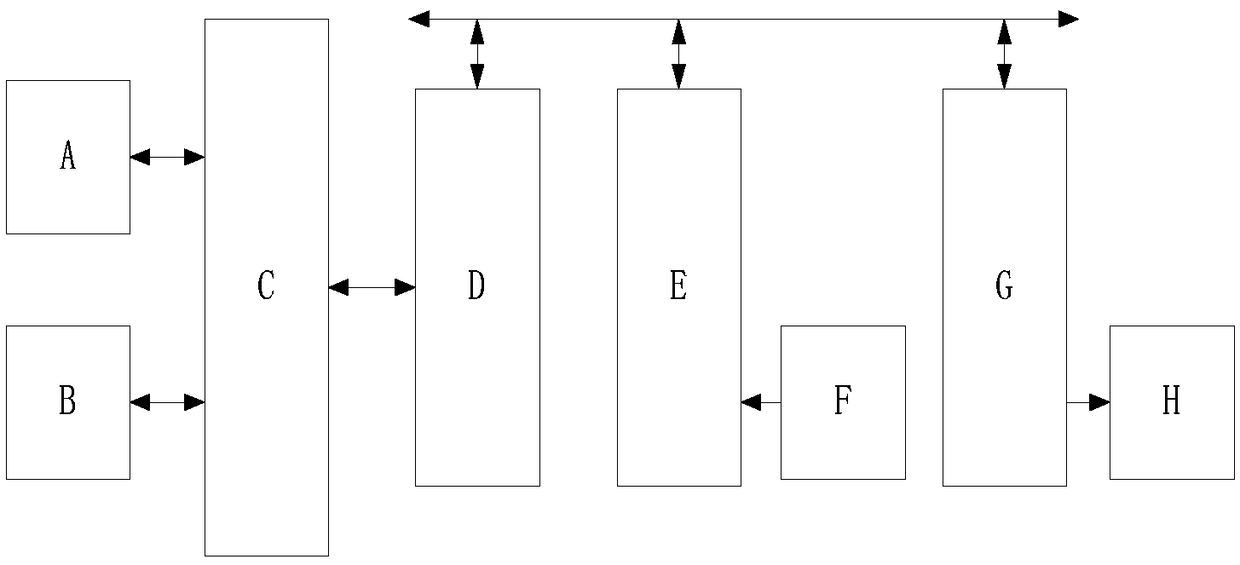

[0051] Such as figure 1 As shown, a thermal power unit simulation manual station of the present invention includes an engineer station A, an operator station B, a switch C, a controller D, an analog input module E, an input terminal board F, an analog output module G and an output Terminal board H; the engineer station A and the operator station B are respectively connected to the switch C through an Ethernet cable, the controller D and the switch C are connected through an Ethernet cable, and the analog input module E and the controller D Through the standard CAN bus connection, the analog output module G and the controller D are connected through the standard CAN bus, the input terminal board F and the analog input module E are connected through the standard DB37 line, and the analog output module G Connect with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com