Inspection robot fixed-point inspection method

An inspection robot and robot technology, applied in the field of inspection robots, can solve problems such as poor practicability and inconvenient laying, and achieve the effect of expanding the work area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

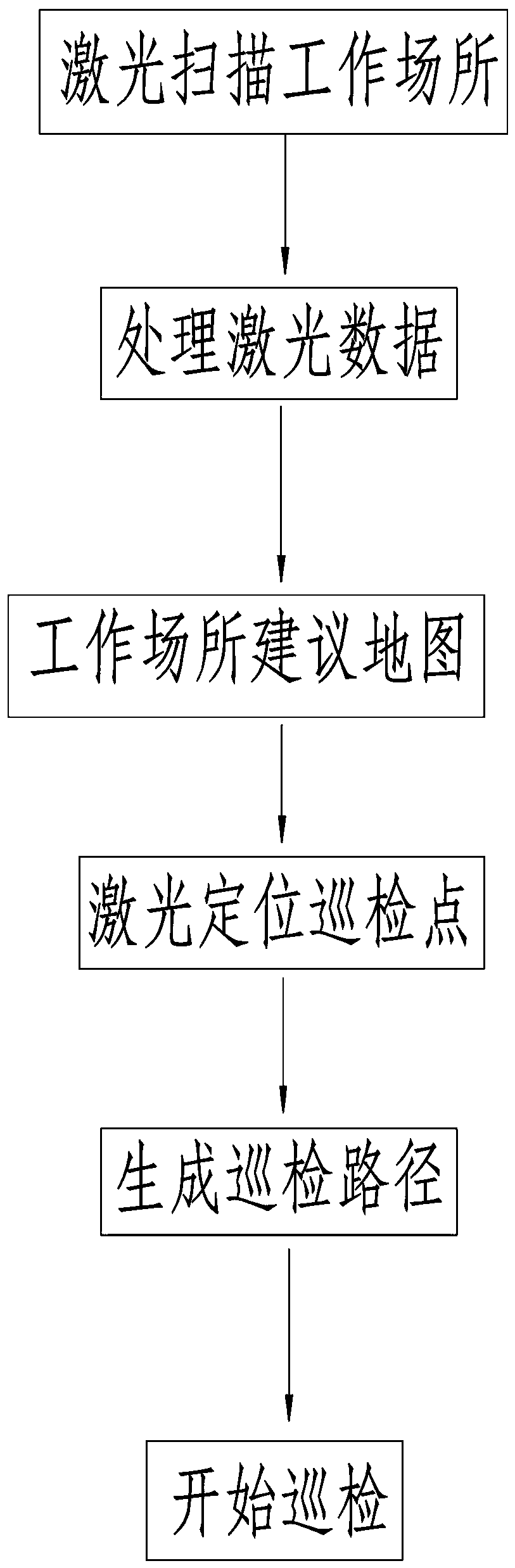

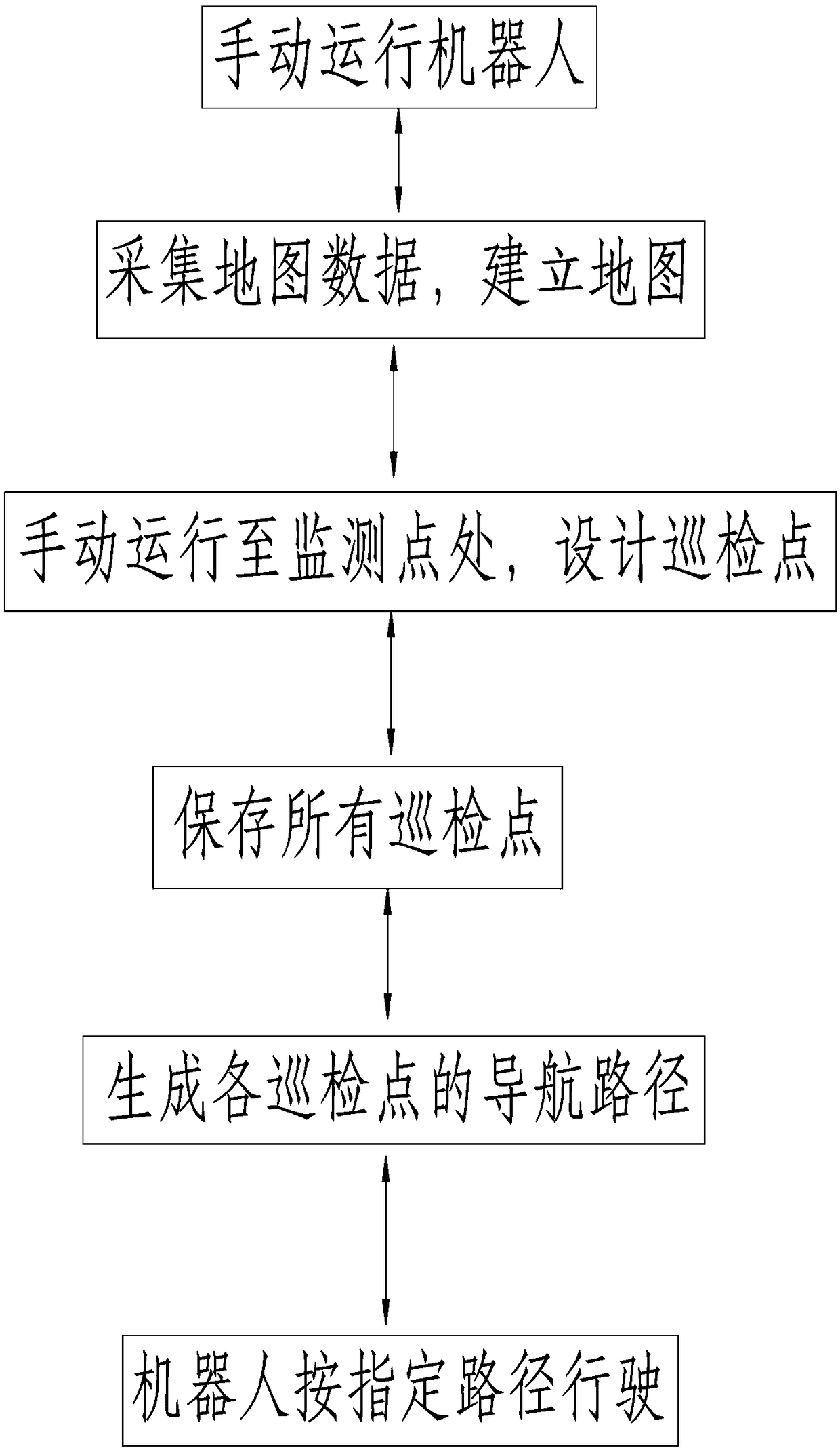

[0018] refer to Figure 1-3 , a fixed-point inspection method for an inspection robot, the steps of which include the following:

[0019] A: Install a laser scanner on the front of the robot, run the robot manually in the workplace, make the laser scanner on the robot scan the workplace and record the laser scanning data;

[0020] B: Build a map of the workplace based on laser scanning data and determine the origin of the robot's operation;

[0021] C: Run the robot to the inspection point that needs to be monitored, determine the current coordinates of the robot according to the laser positioning and save it;

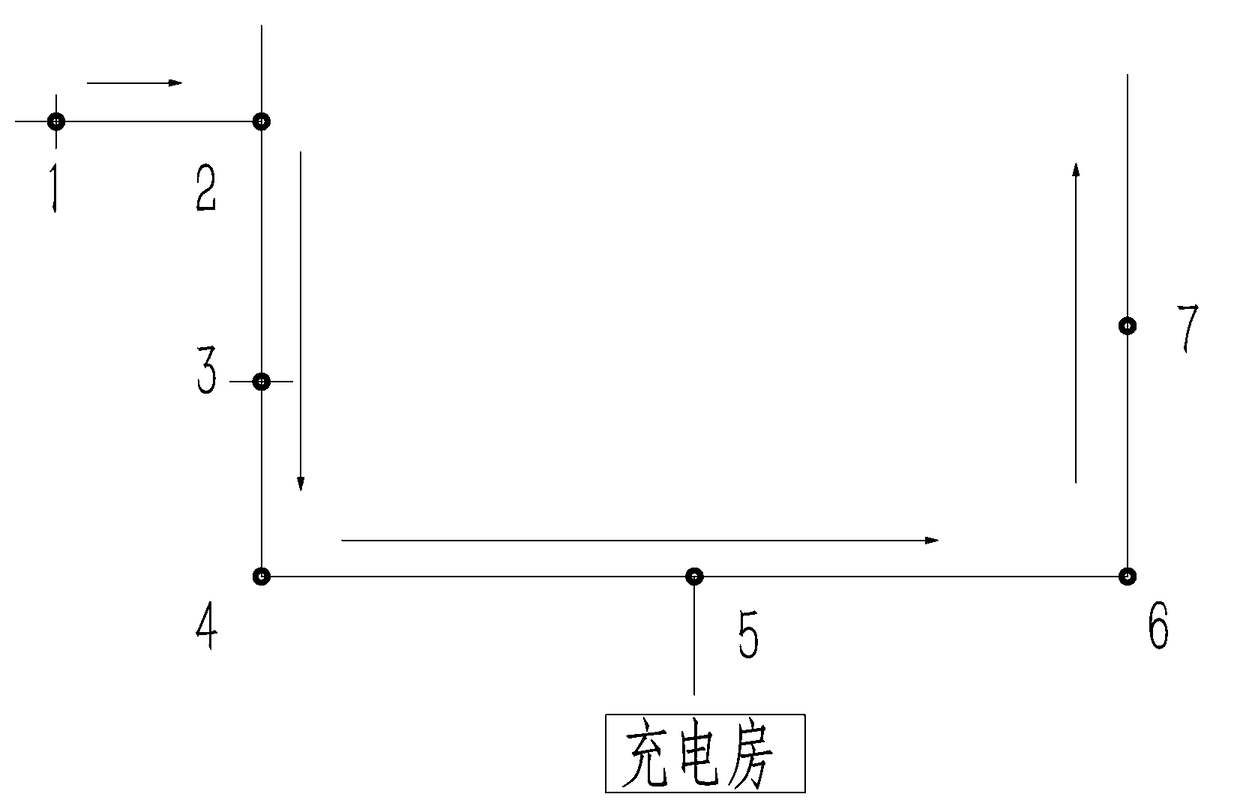

[0022] D: Display the origin and all inspection points on the map, and generate a robot-operable inspection path based on the inspection points, and the robot will run in the workplace according to the specified path.

[0023] In the above method, when the robot is moving forward in the actual running path, the laser locates the current coordinates of the robot, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com