A design and implementation method of oblique wedge module

A realization method, wedge technology, applied in the direction of design optimization/simulation, calculation, special data processing applications, etc., can solve problems such as environmental complexity and high degree of difficulty, achieve speed and efficiency, improve design efficiency, and eliminate duplication of labor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

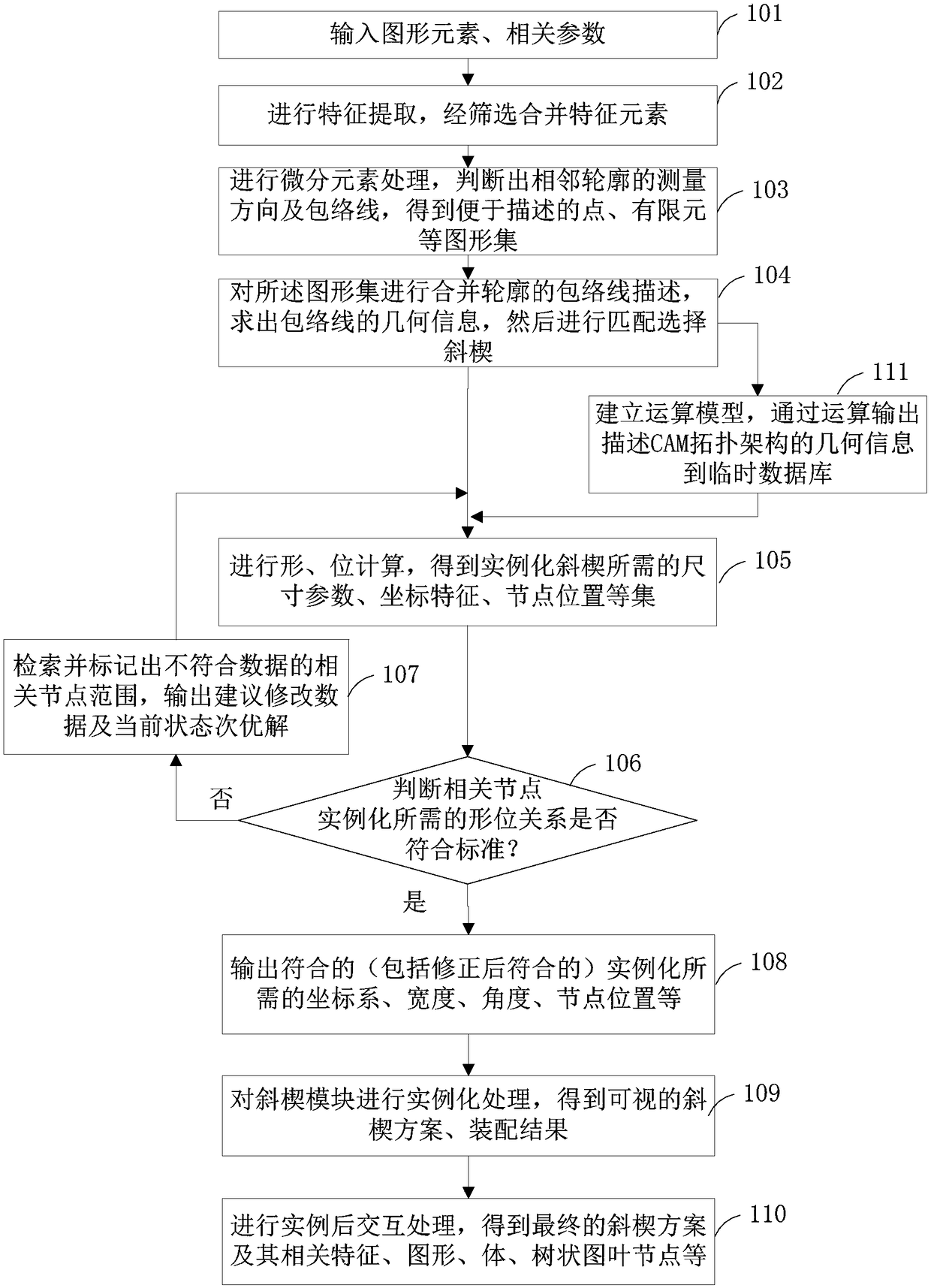

[0029] The method of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments of the present invention.

[0030] figure 1 It is a schematic flowchart of the design and implementation method of the wedge module in the embodiment of the present invention.

[0031] Such as figure 1 As shown, the design and implementation method of the wedge module mainly includes the following steps:

[0032] Step 101: Input graphic elements and related parameters. The input graphic elements and related parameters are specifically inputting the contour direction of the superior node CAM and the model data of the CAM, including the contour of the fixed seat, the shaft system of the contour of the fixed seat, length (L_t), width (W_t), stroke (ST_t) , force (F_t), processing force (F_w) related to the contour of the holder, and stroke (ST_w) related to the contour of the holder.

[0033] Step 102: Perform feature extraction, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com