A live installation method of a low-voltage arrester

An installation method and surge arrester technology, applied in the field of surge arresters, can solve problems such as unfavorable safe operation of live equipment for operator personal safety, affecting the continuous operation rate of power supply equipment, limited space inside the installation cabinet, etc. Hand operation, small length and size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

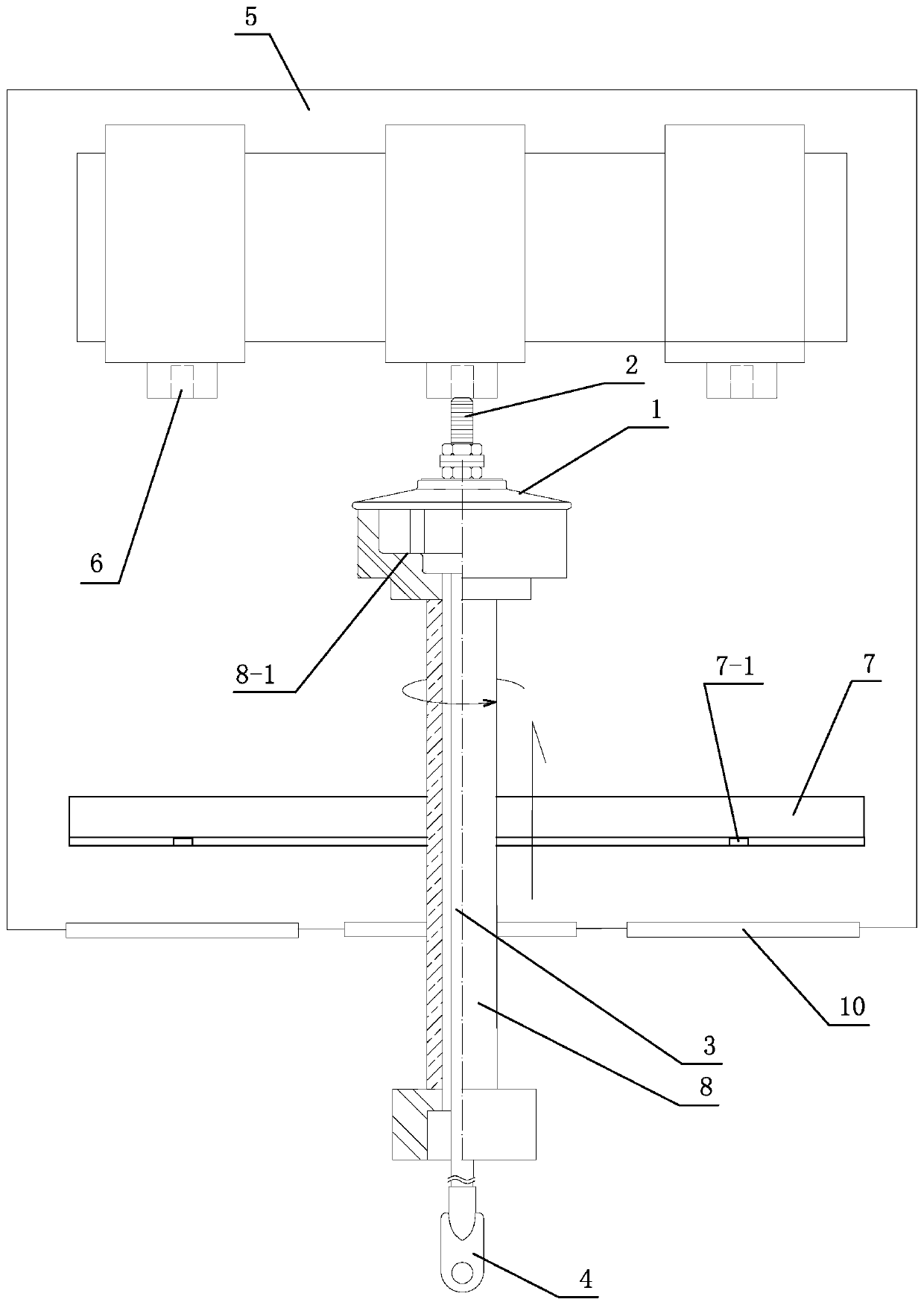

[0047] The present invention will be further described below in conjunction with the accompanying drawings.

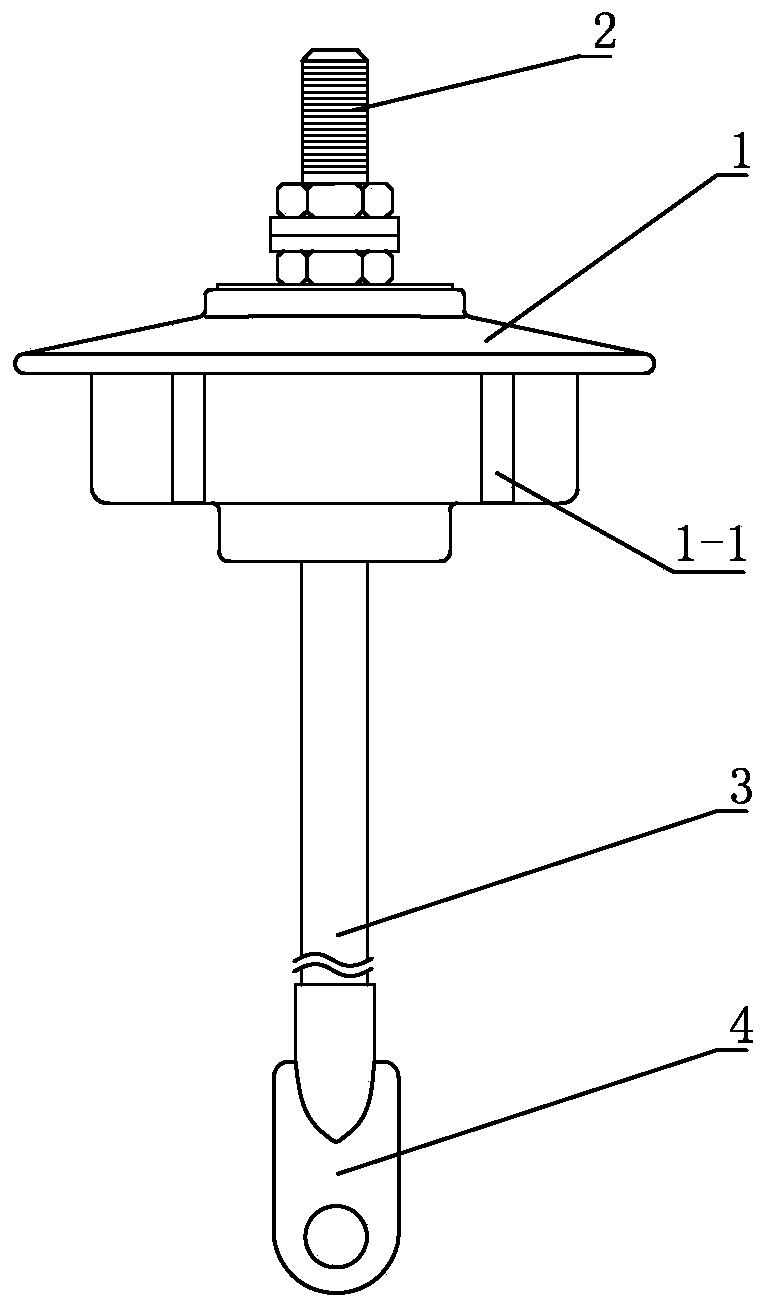

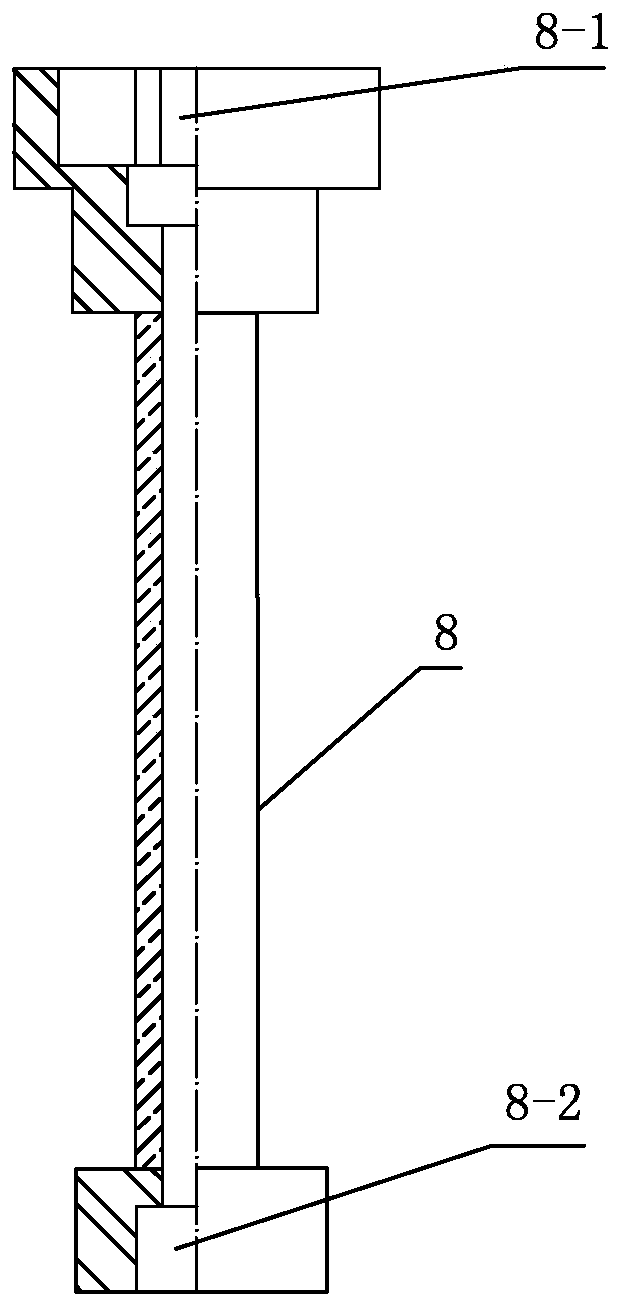

[0048] figure 1 Among them, the technical solution of the present invention provides a live installation method of a low-voltage arrester, the low-voltage arrester includes a connection terminal located at the upper end of the low-voltage arrester body 1, and a grounding lead 3 located at the lower end of the low-voltage arrester body for connecting to the ground electrode , the low-voltage arrester is installed in the field cabinet 5 on the pole; a three-phase knife switch is arranged in the field cabinet, and a low-voltage lightning arrester is installed correspondingly under each phase knife switch; it is characterized in that :

[0049] On the terminal post at the lower end of the operating knife switch in the field cabinet, a vertical internal thread interface 6 is set;

[0050] On the connection terminal on the upper end of the low-voltage arrester body, an ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com