FPC steel sheet mold inner back rubber mold

A technology of steel sheet and back glue, which is applied in the direction of electrical components, printed circuit manufacturing, printed circuit, etc., can solve the problems of scattered processing, large investment, troublesome manufacturing, etc., and achieve the effects of improved production efficiency, guaranteed processing accuracy, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

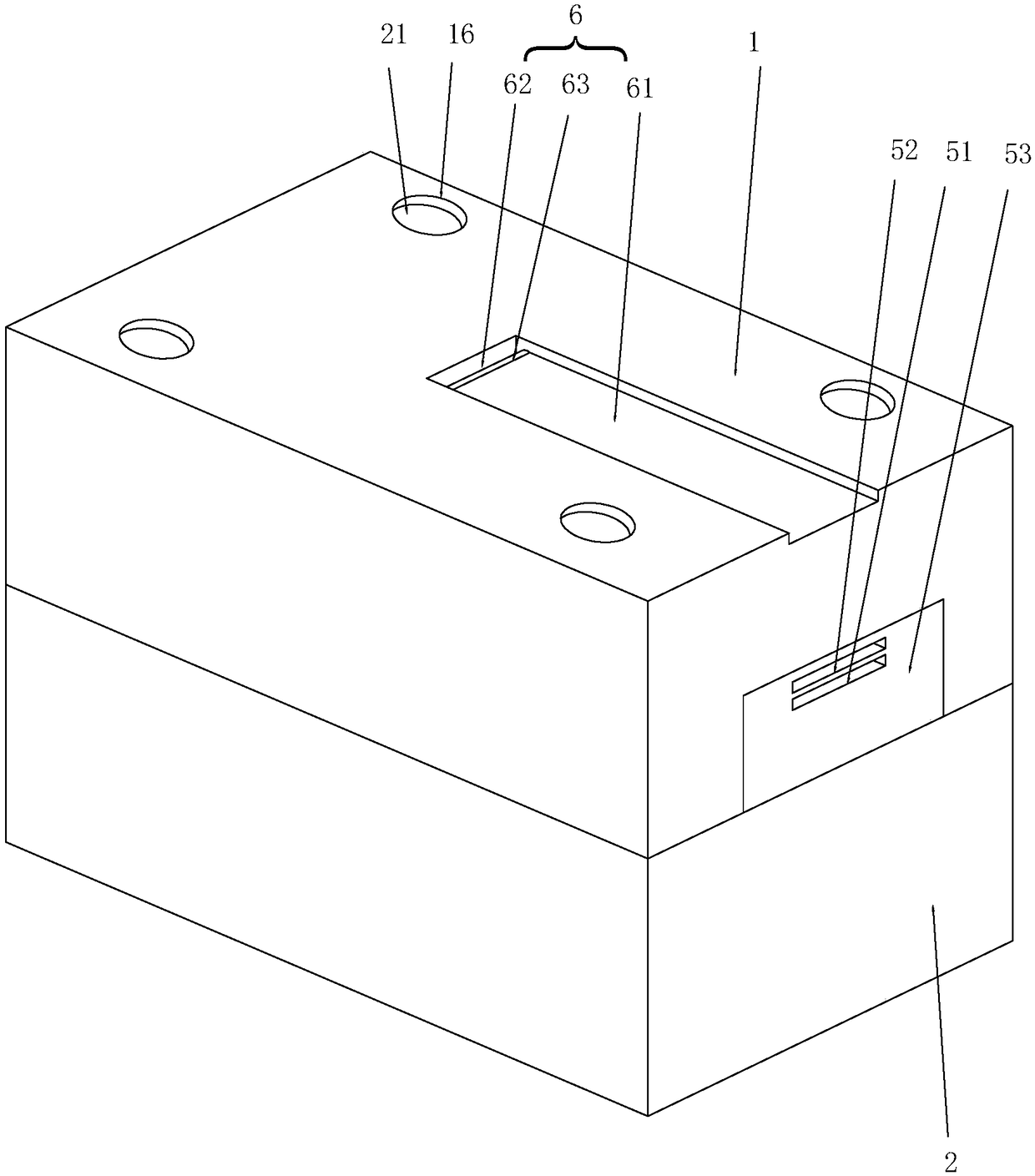

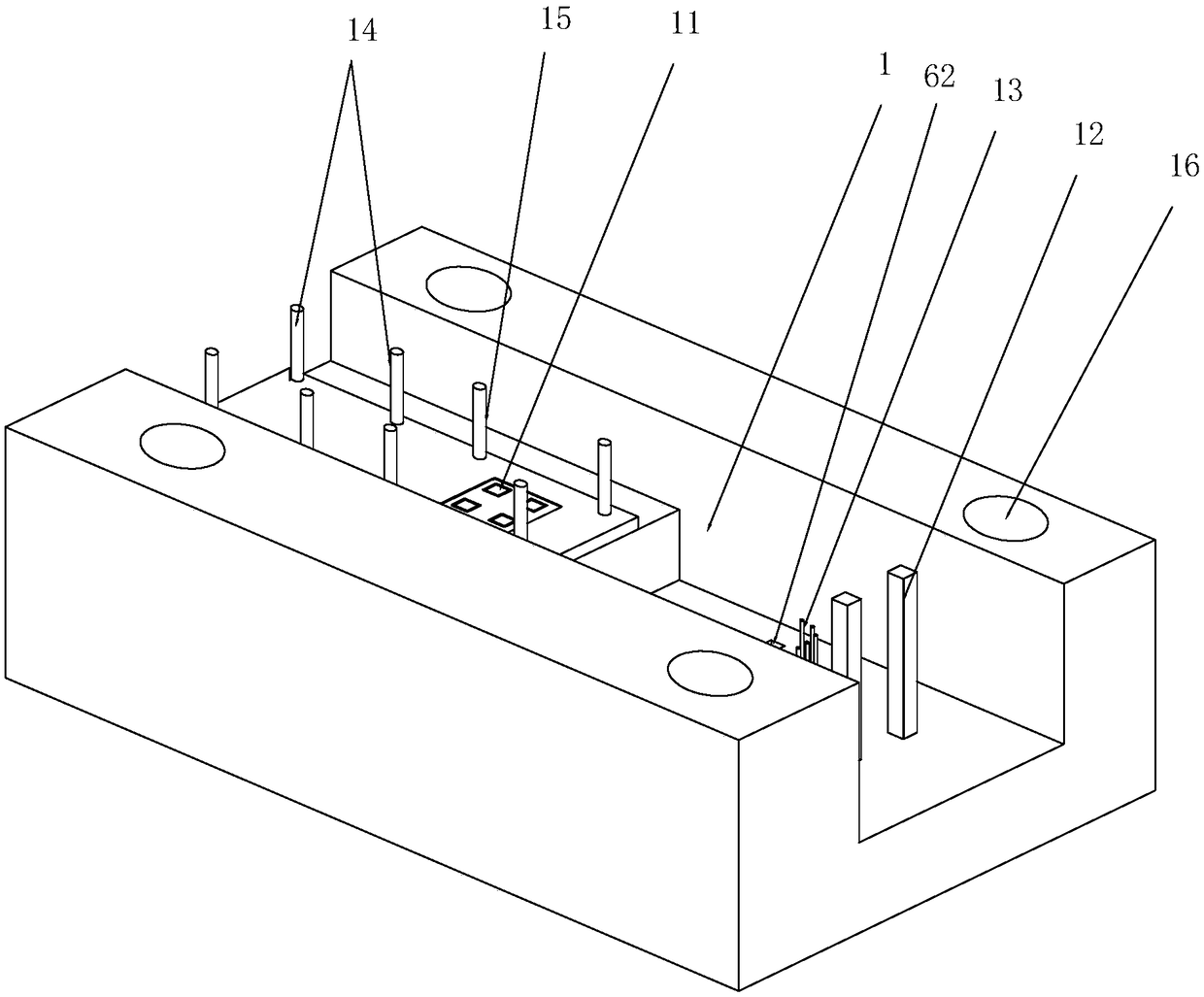

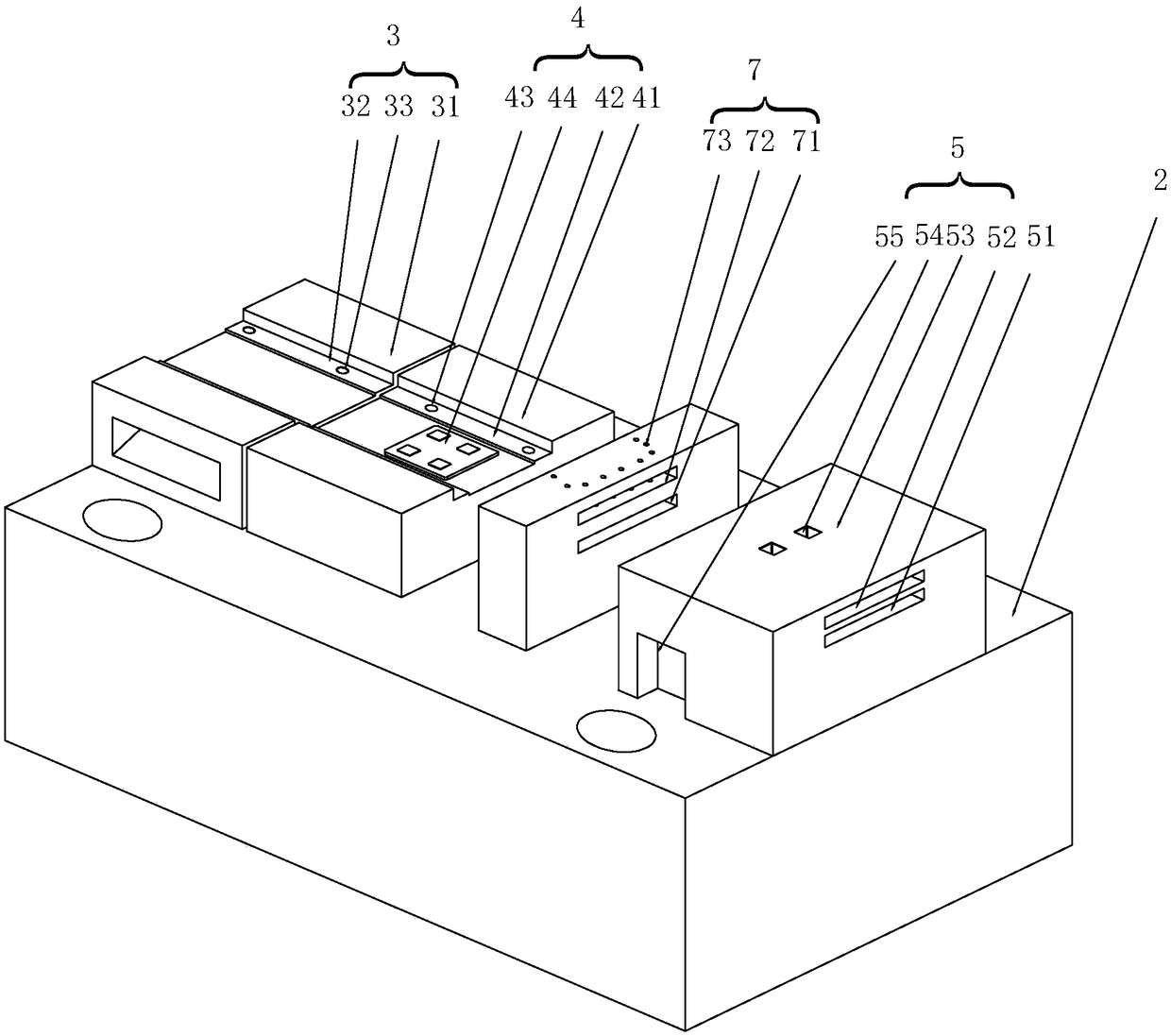

[0021] see Figure 1 to Figure 4 , a kind of FPC steel sheet mold in-mold adhesive mold of the present invention, comprises upper mold 1 and lower mold 2, and described lower mold 2 is provided with the positioning group 3 that is used for positioning the base belt, and is used for shaping the FPC steel sheet on the base belt. The shaping group 4 and the stamping group 5 for punching and adhering the thermosetting tape to the FPC steel sheet. It is explained here that the FPC steel sheet in this application has been fixed on the base belt in advance after being punched out from the steel belt. Therefore, when the base belt is transported, the FPC steel sheet also moves with the base belt, which is convenient and reliable. In this way, the feeding and processing of FPC steel sheets can be facilitated. The positioning group 3, the shaping group 4 and the stamping group 5 are arranged in sequence along the base belt conveying direction, and the punching knife 11 for shaping the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com