Microbubble enhanced mineral grading device

A technology of classification device and bubble generation device, which is applied in solid separation, flotation and other directions, can solve the problems of large consumption of chemicals, high ash content, low yield of flotation clean coal, etc., and achieves the improvement of classification efficiency and accurate particle size classification. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

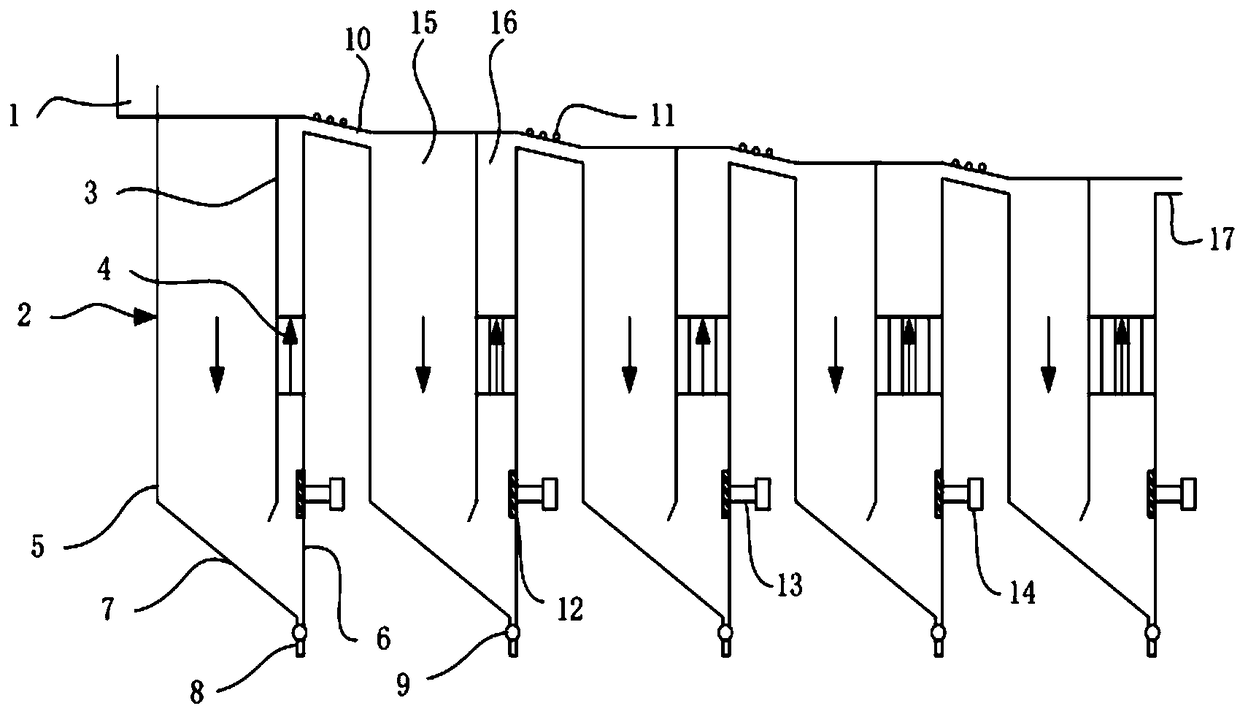

[0022] Below will combine the appended in the present invention figure 1 , attached figure 2 , clearly and completely describe the technical solution in the present invention.

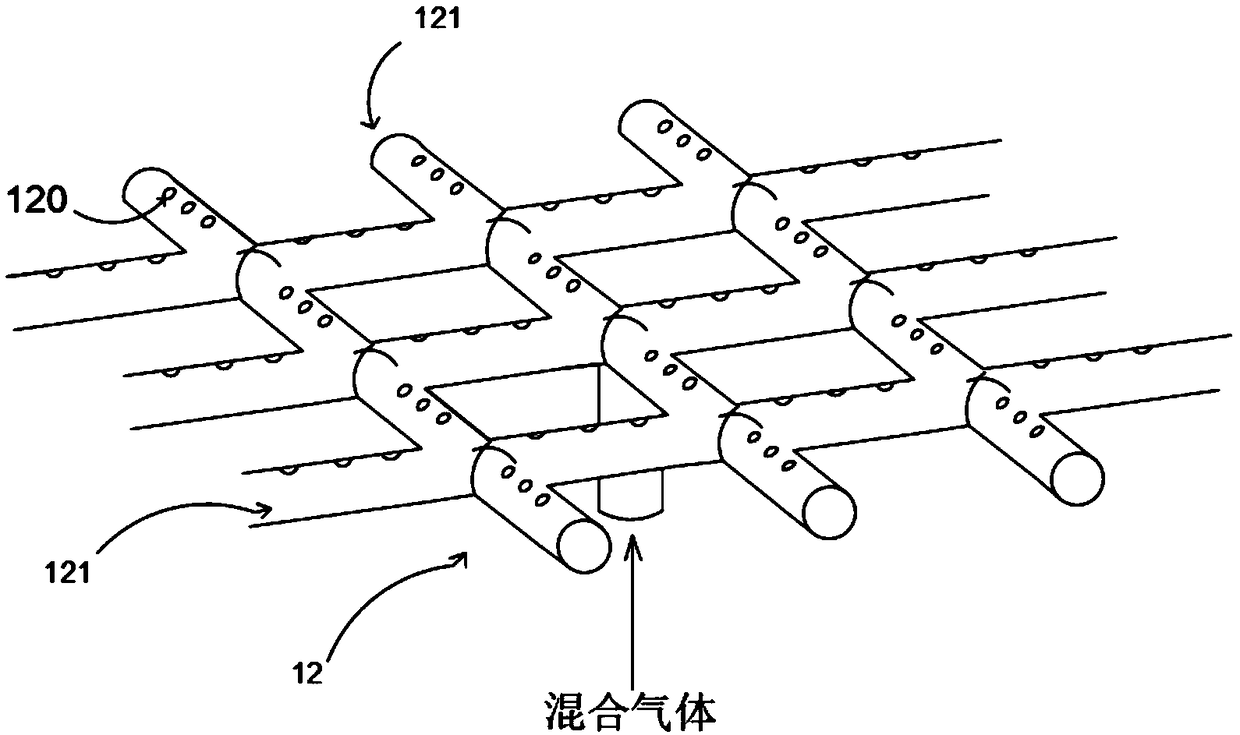

[0023] Such as figure 1 Said, a kind of microbubble strengthened mineral grading device, comprises feeding trough 1, unit pool 2, partition plate 3, rectification tube bundle 4, outer pool wall 5, inner pool wall 6, pool bottom 7, bottom flow pipe 8, control valve 9. Connecting pipe 10, water spray hole 11, bubble generating device 12, 120—air pipe, 121—air hole, air pump 13, air intake pipe 14, inflow area 15, outflow area 16, and discharge pipe 17. It is characterized in that: the microbubble-enhanced mineral grading device includes a plurality of unit pools 2 connected in series, each of the unit pools 2 is connected by a connecting pipe 10 at the top, and the upper end of the first unit pool 2 is set There is a feeding trough 1, and the upper end of the final unit pool 2 is provided with a disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com