Thread rolling cylindrical die repair device

A technology of thread rolling wheel and fixing device, applied in the field of finishing, can solve the problems of low quality, metal separation, slow repair work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

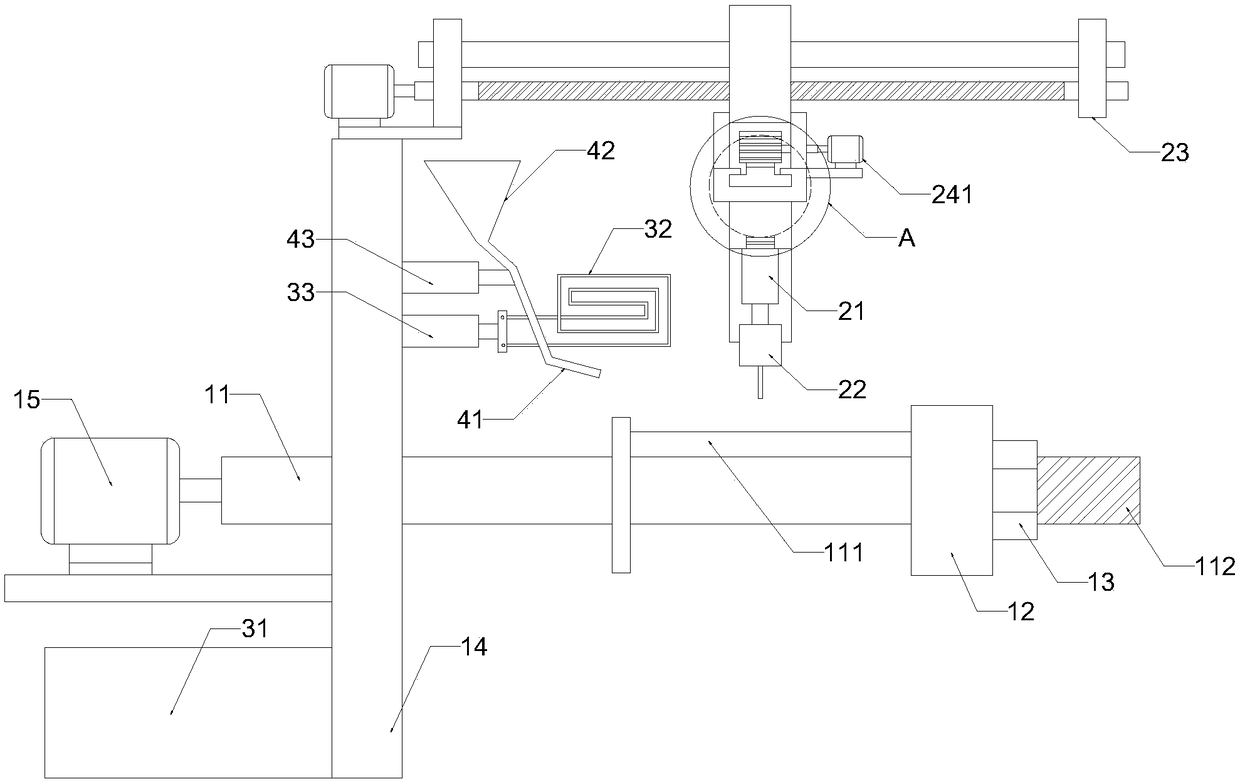

[0033] like Figure 1 to Figure 2 As shown, the thread rolling wheel repair device includes a fixing device for fixing the thread rolling wheel to be repaired, a punching unit for punching the thread rolling wheel repair area, a heating unit for heating the thread rolling wheel repair area, and a Injection unit for injecting repair metal liquid;

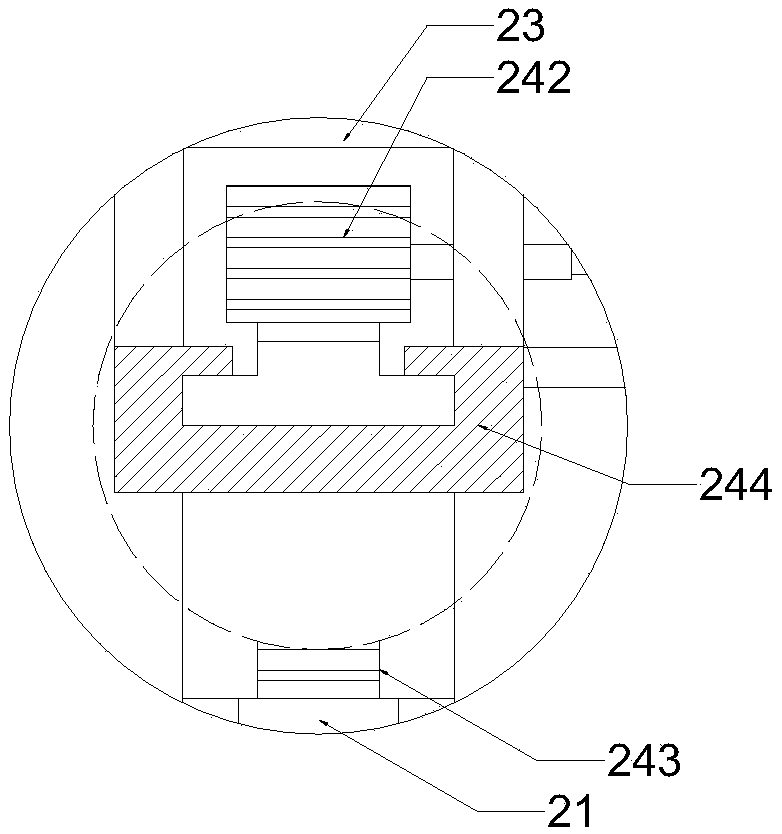

[0034] The punching unit comprises a first cylinder 21, a puncher 22, a horizontal movement mechanism 23 and a circular movement mechanism; on the free end of the first cylinder 21;

[0035] The fixing device is located on the moving side of the circular moving mechanism; both the heating unit and the injection unit are installed on the fixing device.

[0036] The thread rolling wheel can be fixed by the thread rolling wheel fixing device, so that the part to be repaired can always be in a convenient position for operation, and the heating unit can heat the area to be repaired before injecting the molten metal, which can make the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com