Novel combing machine cleaning and dust collecting device

A dust collection device and combing machine technology, which is applied in combing machines, textiles, papermaking, and fiber processing, etc., can solve the problems of dust flying, affecting spinning quality, dust and flying flowers cannot be removed in time, etc. To achieve the effect of improving operating efficiency, improving economic benefits, and rational and practical design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

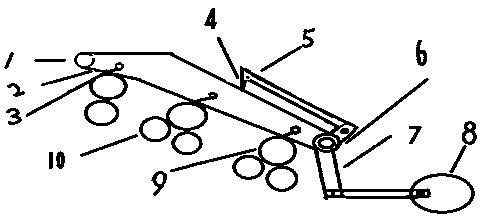

[0009] After the combing machine is started, the additional electrical control device transmits the driving action signal to the servo motor, and the servo motor starts to rotate after receiving the signal. When rotating, it drives the eccentric wheel 8, and the eccentric wheel 8 drives the intermittent power shaft 6 forward through the power shaft swing rod 7. Intermittent movement, the intermittent power shaft 6 drives the cleaning velvet belt 2 and the velvet belt carding piece 4 to perform intermittent reciprocating motion. After accumulating into bundles, the suction device quickly sucks them away to ensure the stable quality of comber sliver.

[0010] After the device of the present invention, fly and dust can be cleaned in time, which is conducive to the orderly movement of fibers in the drafting area, reduces the failure shutdown caused by poor cleaning, improves the operation efficiency of the comber, and saves production costs. Meet the needs of production and produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com