Rubber ball hinge for reducing radial/axial rigidity ratio and assembling method of rubber ball hinge

A technology of rubber ball hinge and axial stiffness, which is applied in the direction of pivot, shaft and bearing, pivot connection, etc., can solve the problems of excessive rubber end surface area of rubber ball hinge and large radial/axial stiffness ratio, etc. Achieve the effects of increasing torque, reducing radial/axial stiffness ratio, and improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

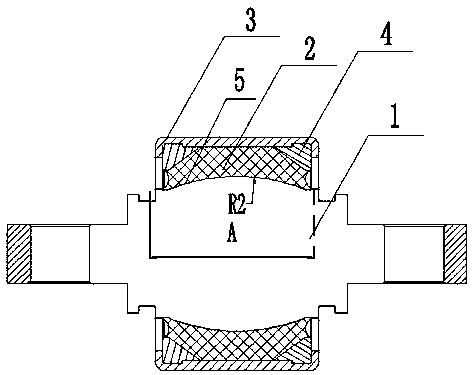

[0035] see figure 1 , this embodiment provides a rubber ball joint that reduces the radial / axial stiffness ratio. The rubber ball joint includes a metal mandrel 1, a rubber layer 2, a metal jacket 3 and a metal end cap 4. The rubber layer 2 is vulcanized and bonded to the metal On the mandrel 1, the metal jacket 3 is set on the outside of the rubber layer 2 and the metal end cap 4, and the metal end cap 4 is directly assembled or vulcanized and bonded to both ends of the rubber layer 2 to prevent the rubber from extruding from both ends of the rubber layer 2 .

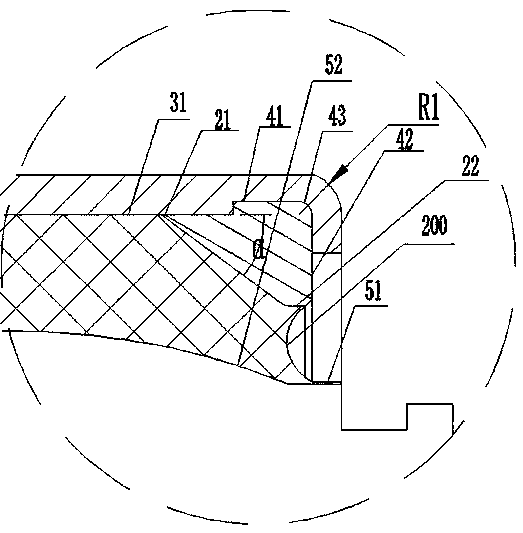

[0036] Such as figure 2 As shown, the metal end cap 4 includes a stepped portion 41 and an annular portion 42, the annular portion 42 is connected to one end of the stepped portion 41, the annular portion 42 and the stepped portion 41 are transitionally connected by a fillet-43, and the circle of the fillet-43 The radius of the arc is R1, and the metal end cap 4 is wrapped into a whole by the flanging of the metal j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com