Vibration reduction method of automotive lamp and anti-vibration automotive lamp

A technology for vehicle lamps and lamp bodies, which is used in motor vehicles, road vehicles, vehicle parts, etc., can solve the problems of strict test requirements of the main engine of automobiles, solve the problems of fracture and powder, improve the pass rate, and improve the anti-vibration performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

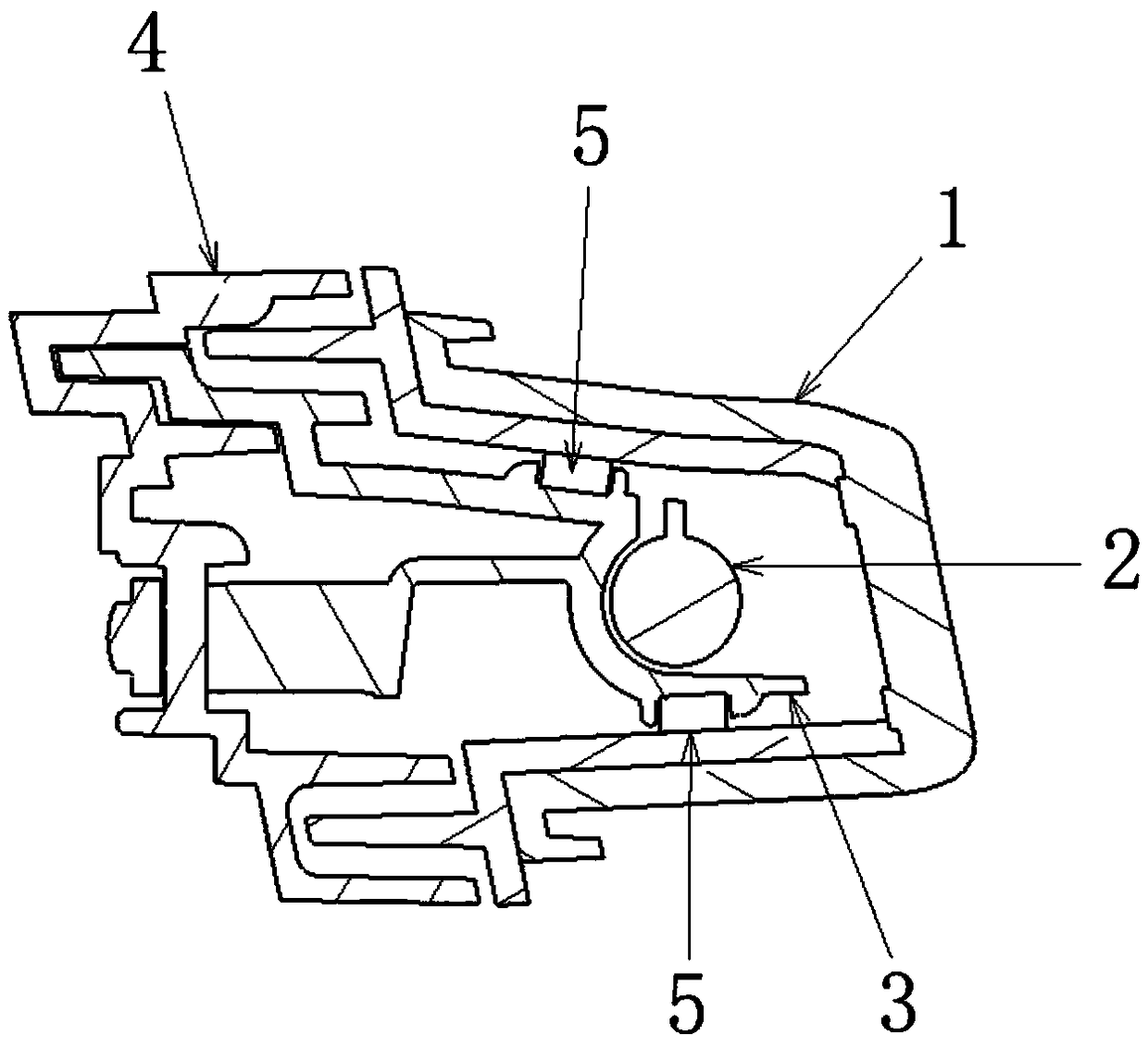

[0019] The invention discloses a method for improving the vibration of a car lamp. A plurality of elastic material blocks are dispersedly arranged between the lamp body of the car lamp and the illuminant bracket for supporting the illuminant of the car lamp. The lamp body of the car lamp and the luminous body bracket exist in a pre-compressed state in the linear direction, and the elastic material blocks play the role of reducing the amplitude of the luminous body bracket, thereby reducing or preventing the jitter of the luminous body during the use of the car lamp. For the principle of anti-vibration, please refer to the relevant description in the anti-vibration lamp later.

[0020] The illuminant bracket is directly fixed on the lamp body of the vehicle light. Due to the limited space, usually the illuminant bracket is only fixedly connected with the lamp body at the rear end. At this time, the elastic material block is preferably arranged far away from the The position whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com