A detection method for easy-open rivet structure

A detection method and easy-open lid technology, applied in the direction of measuring devices, optical testing flaws/defects, instruments, etc., can solve problems such as drop-off of pop-top cans, liquid leakage, correction, etc., to solve product quality problems, solve drop-off pull The effect of bad and accurate product quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

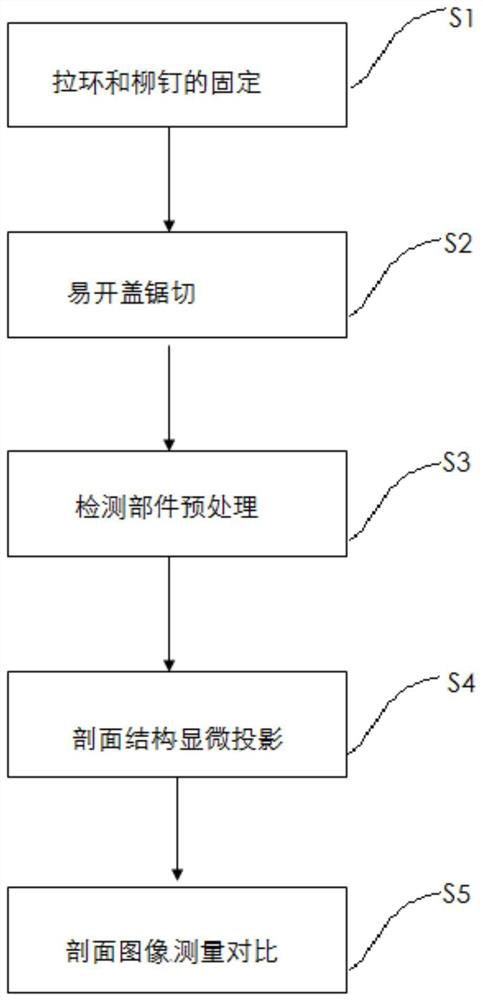

[0024] Such as figure 1 As shown, the schematic diagram of the detection method of the easy-open rivet structure of the present invention can be clearly seen from the figure. The detection method of the easy-open rivet structure of the present invention includes the following steps: S1: pull ring and Fixing of the rivet, the pull ring and the rivet are fixed by instant adhesive curing and drying; S2: sawing the easy open cover, sawing the easy open cover into two parts on average along the diameter of the rivet, and retaining the part with the pull ring as Detecting parts; S3: Pretreatment of the testing parts, grinding the sawing section of the testing parts until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com