Method for continuously measuring transverse tensile strength of reel material and application of method

A transverse stretching and reeling technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of flexible selection of inconvenient detection points, large workload, etc., and achieve the effect of simple operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

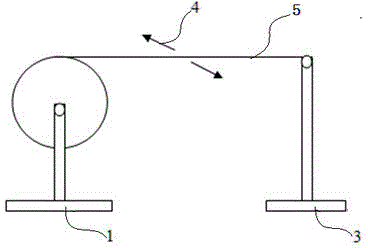

[0038] Such as figure 2 As shown in the measurement schematic diagram, the present embodiment continuously measures the transverse tensile strength of the reel material with the following steps:

[0039] S1. Set the reel material fixing device 1 and the reel material collecting device 3, the said fixing device 1 continuously conveys the reel material to the collecting device 3 through the rotation of its shaft, and the collecting device 3 collects the reel material by rotating to ensure that both The reel material 5 between is horizontal state;

[0040] S2. A tensile strength measuring device 4 is arranged between the reel material fixing device 1 and the reel material collecting device 3;

[0041] S3. Use the tensile strength measuring device 4 to measure the transverse tensile strength of the reel material between the fixing device 1 and the collecting device 3, collect the measured reel material by rotation, and select the next measuring point at the same time.

Embodiment 2

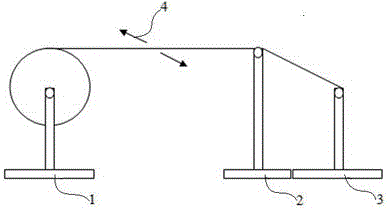

[0043] In this embodiment, a detection device is designed according to the detection method of the present invention as attached image 3 shown. attached figure 2 Among them, 1 is the reel material fixing unit, 2 is the material changing component, 3 is the material collecting component, and 4 is the tensile strength tester.

[0044]The material collection assembly 3 rotates and collects the measured material in an electric manner, and at the same time selects the next measuring point. When the stop button is pressed, the collection assembly stops rotating, which can realize random stop collection of materials.

[0045] The detection steps of the present invention are as follows:

[0046] Select the shaft whose diameter matches the core diameter of the reel material to be tested, load the material to be tested into the reel material fixing unit, adjust the clamp on the shaft, and fix the reel material on the shaft;

[0047] Select a shaft whose diameter matches the core d...

Embodiment 3

[0052] The difference from Example 2 is that the material collection assembly adopts an electric method that can set a fixed distance to stop collection, and can automatically realize the fixed distance between measurement points. After measuring the tensile strength of the first point, the measured material can be rotated and collected by electric means, and at the same time stop selecting the next measuring point after a fixed distance (such as 20 cm).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com