Contact detection device for blade wax model of gas turbine engine and detection method thereof

A technology of engine blades and detection devices, applied in the direction of measurement devices, instruments, etc., can solve problems such as measurement result errors, and achieve the effects of improving rigidity, improving accuracy, and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

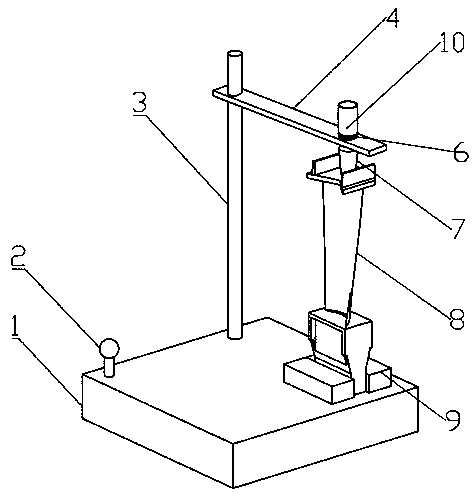

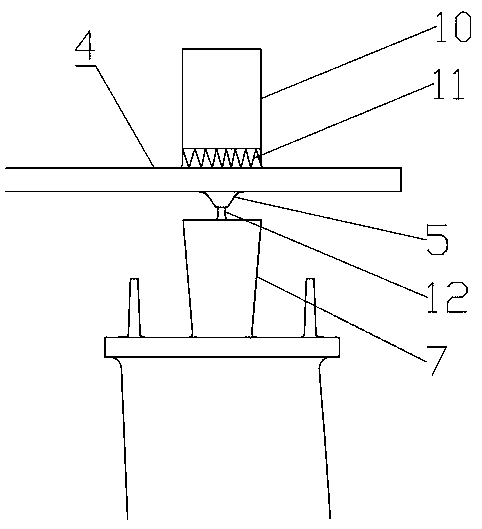

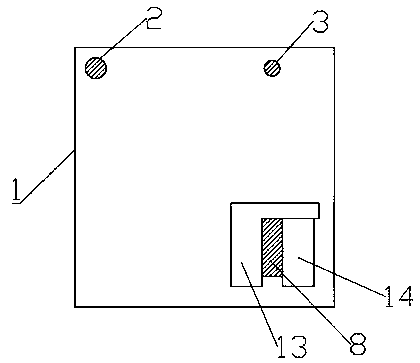

[0029] refer to figure 1 and 2 ,

[0030] A contact detection device for a gas turbine engine blade wax pattern, the detection device includes a base 1, a craft ball 2, a blade wax pattern 8 and a measuring device; the measuring device includes a vertical bar 3, a horizontal bar 4, a chemical material port 5. The heating device 6 and the clamping device 9; the base 1 is set on the coordinate measuring machine; the craft ball 2 is fixed on the base 1 for positioning; the vertical rod 3 is vertically fixed on the base 1; The cross bar 4 is movably connected with the vertical bar 3, and the height of the cross bar 4 is adjustable; the chemical material opening 5 is fixed on the cross bar 4; the chemical material opening 5 is provided with a heating device 6; the blade wax The mold 8 is clamped vertically on the base 1 with a clamping device 9; the top of the blade wax mold 8 is fixedly provided with a wax mold riser 7, which is used to bond with the wax material that is natural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com