Tension monitoring device for mining endless rope winch

A technology of endless rope winches and monitoring devices, applied in the direction of tension measurement, etc., can solve problems such as hidden dangers of operation safety, burden of twisted ropes, slipping of steel wire ropes, etc., achieving high safety and avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

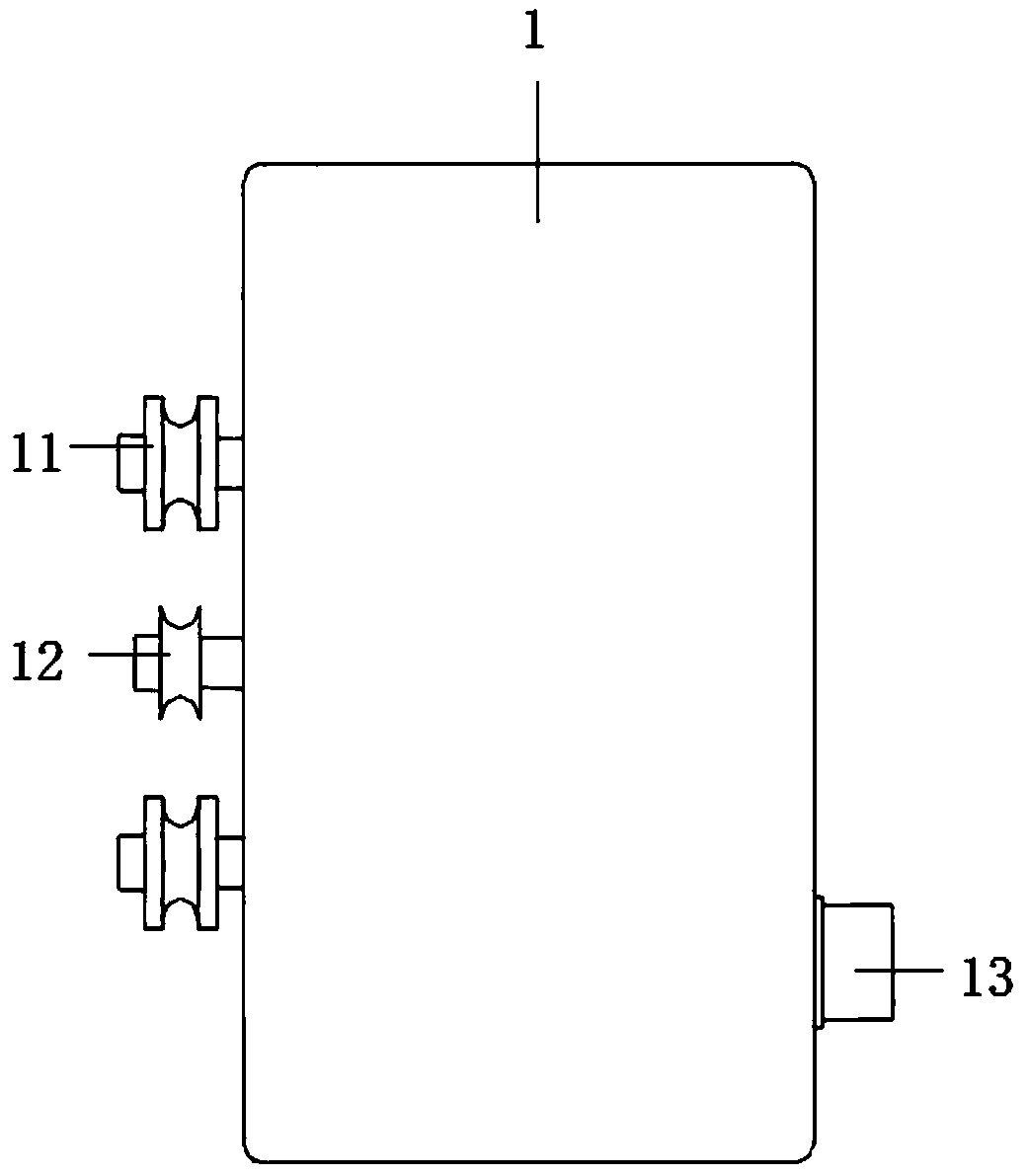

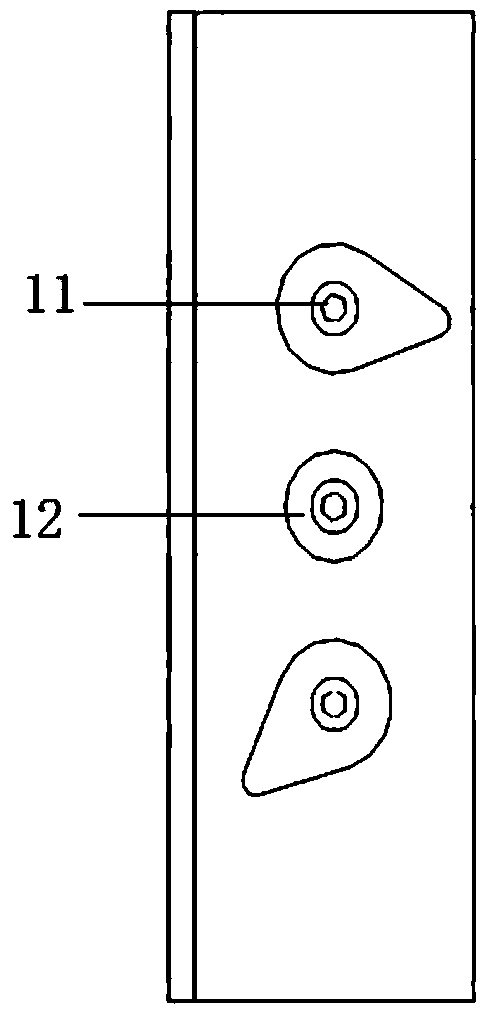

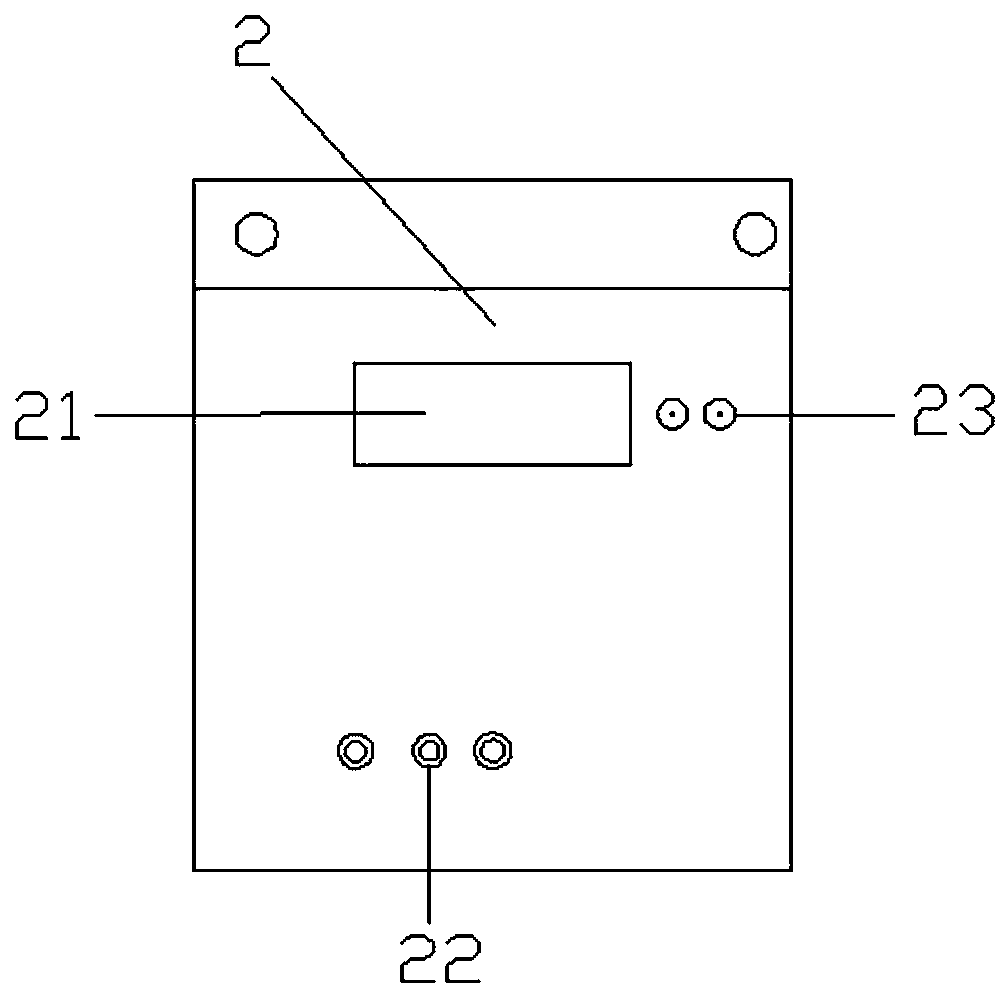

[0019] The embodiment of the invention discloses a tension monitoring device for a mine-used endless rope winch that monitors the tension of the twisted rope in real time, has accurate readings, and can automatically alarm and suspend work. It specifically includes: a dynamometer and a display 2. connection, the force measuring instrument includes a tension wheel 12 and an anti-jumper 11.

[0020] The present invention improves the product structure and monitors the main and auxiliary twisted ropes in real time at the same time, so that the tension value can be visualized. If the tension is too large or too small, an alarm will be issued and the work will be suspended, which improves the safety of the work, and has a high degree of intelligence. It is accurate and reduces the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com