New energy vehicle battery box end cap

A technology for new energy vehicles and battery boxes, which is applied to battery covers/end covers, battery pack components, battery boxes/coats, etc., and can solve problems such as unstable performance, complicated process, and impact on sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

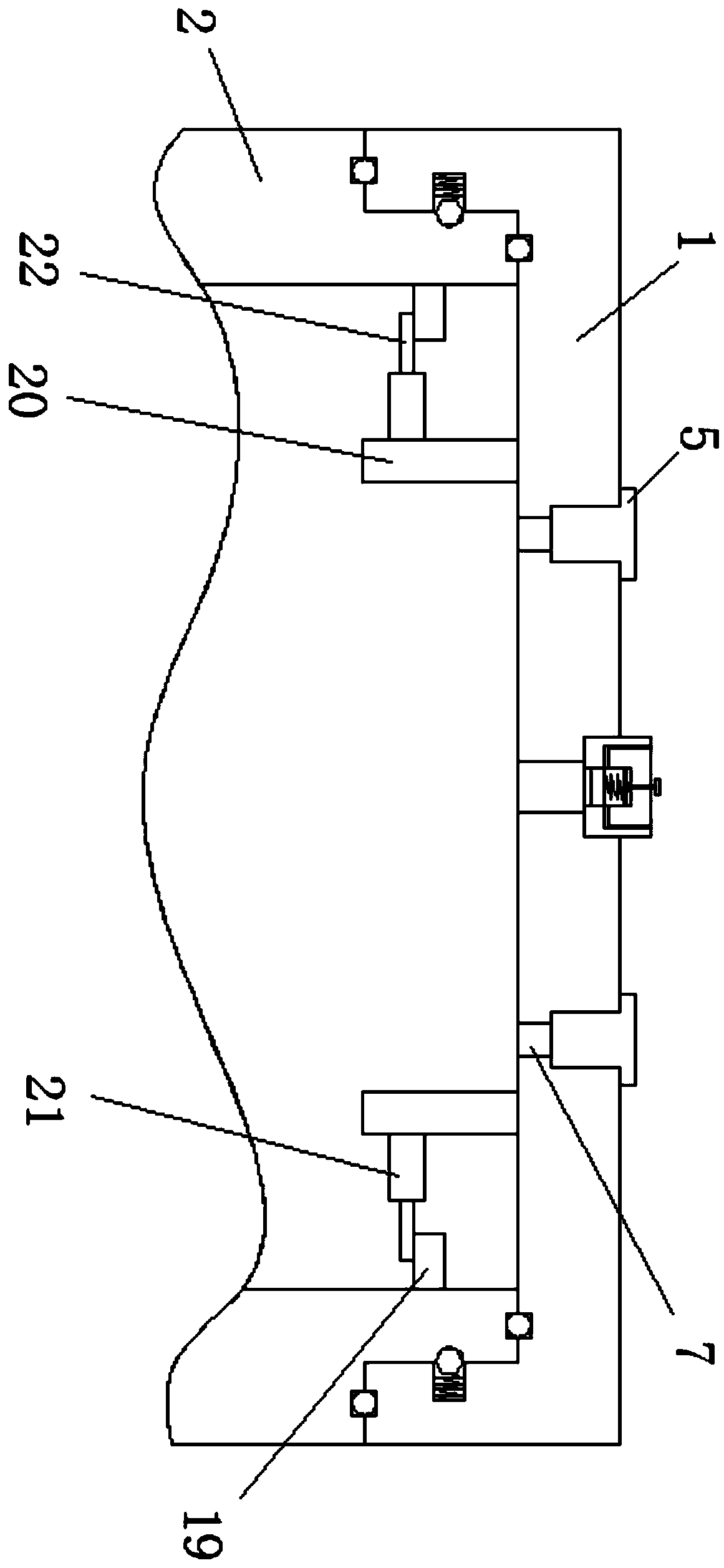

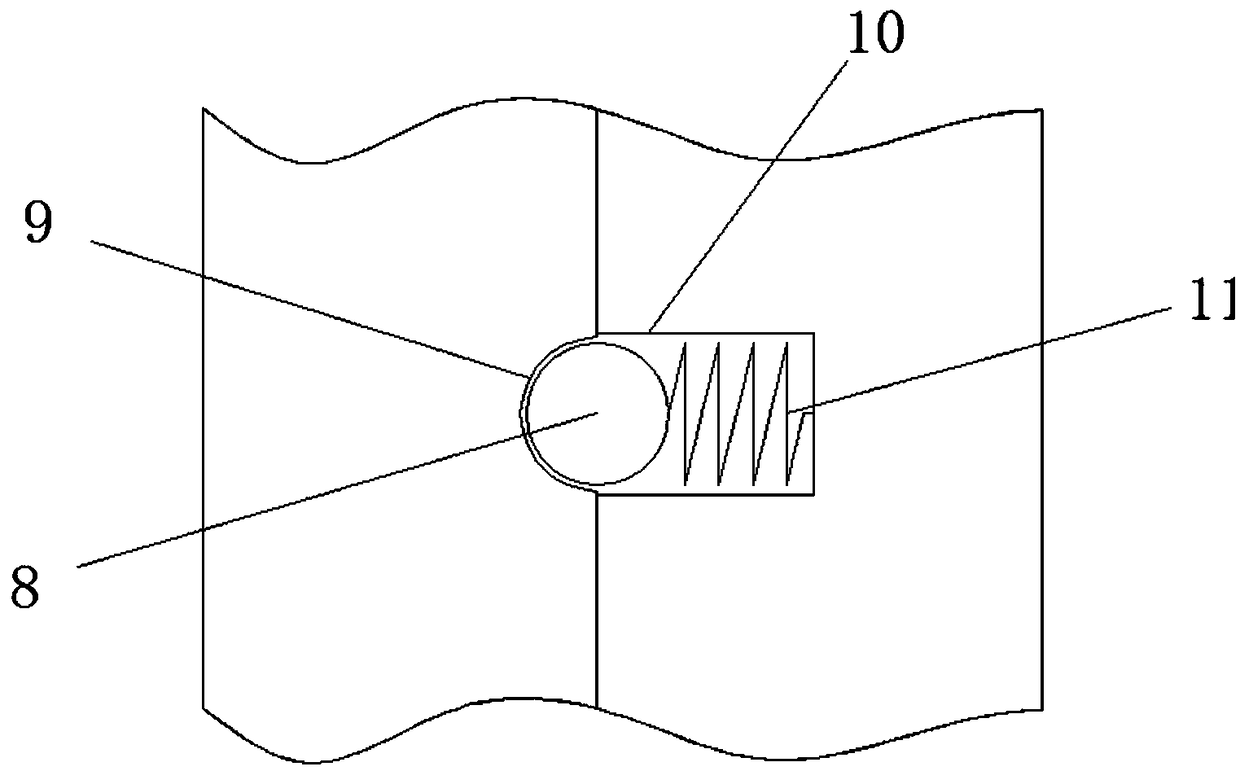

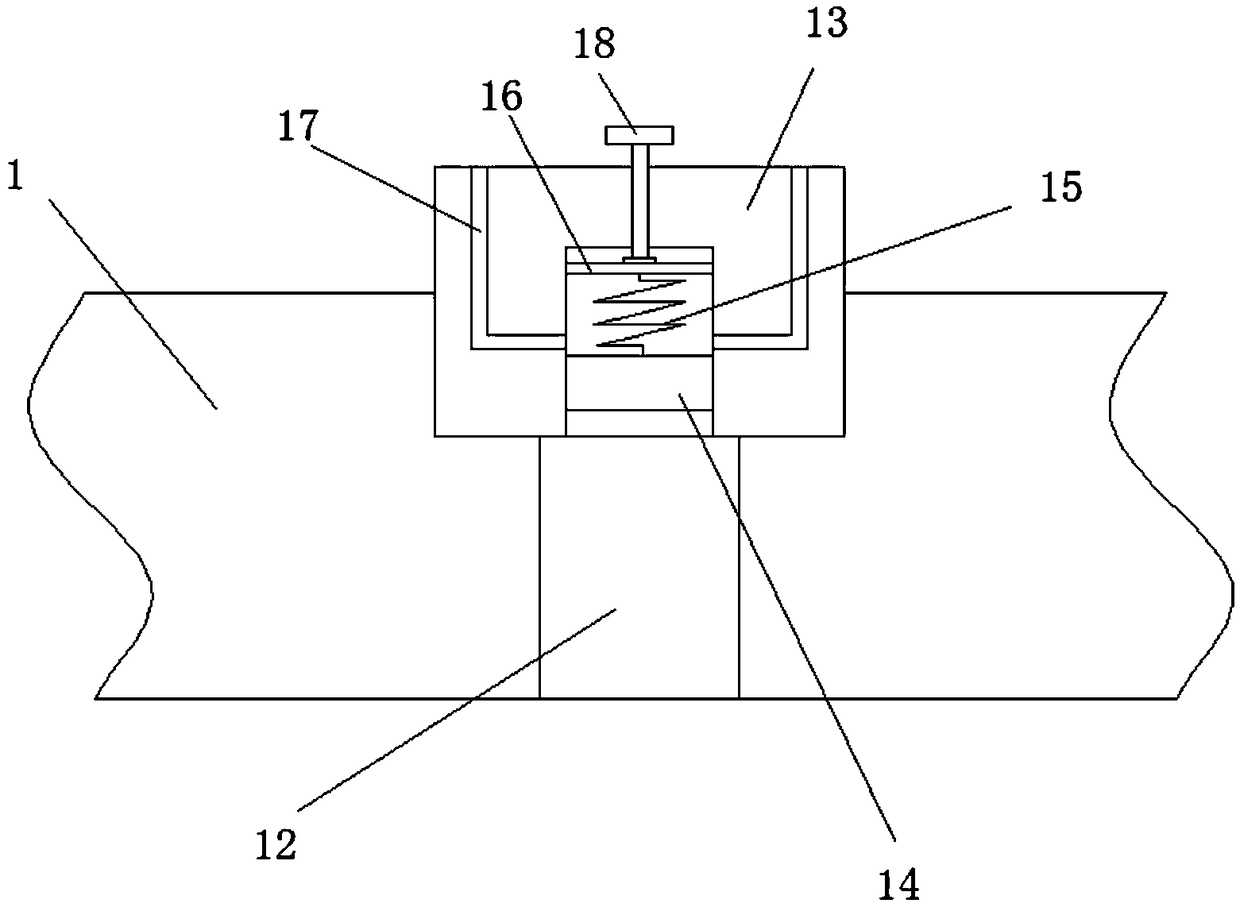

[0015] Such as figure 1 The shown battery box end cover of a new energy vehicle includes an end cover main body 1, the end cover main body 1 is installed on the top of the battery box shell 2, and the lower end of the end cover main body 1 is connected to the battery box shell 2. A positioning mechanism is provided between the upper ends of the battery box housing 2. Limit seats 19 are provided on the inner walls on both sides of the upper end of the battery box shell 2. Two mounting plates 20 are provided at the bottom of the end cover main body 1. The described An electric cylinder 21 is respectively connected to the two mounting plates 20, and the electric cylinder 21 is connected to the limit plate 22, and the limit plate 22 extends to the bottom of the limit seat 19 under the action of the electric cylinder 21, The top of the end cover main body 1 is also provided with a connection hole 7 , and the upper end of the connection hole 7 is connected with a terminal post 5 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com