Hand slipping preventive socket shell

An anti-slip, socket technology, applied in the parts of the connection device, cooling/ventilation/heating transformation, electrical components, etc., can solve the difficulty of inserting or pulling out the electrode sheet, the socket enters the self-protection mode, and the heat dissipation effect is not good. and other problems, to achieve the effect of improving the overall structural strength, preventing low frictional resistance, and improving the heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

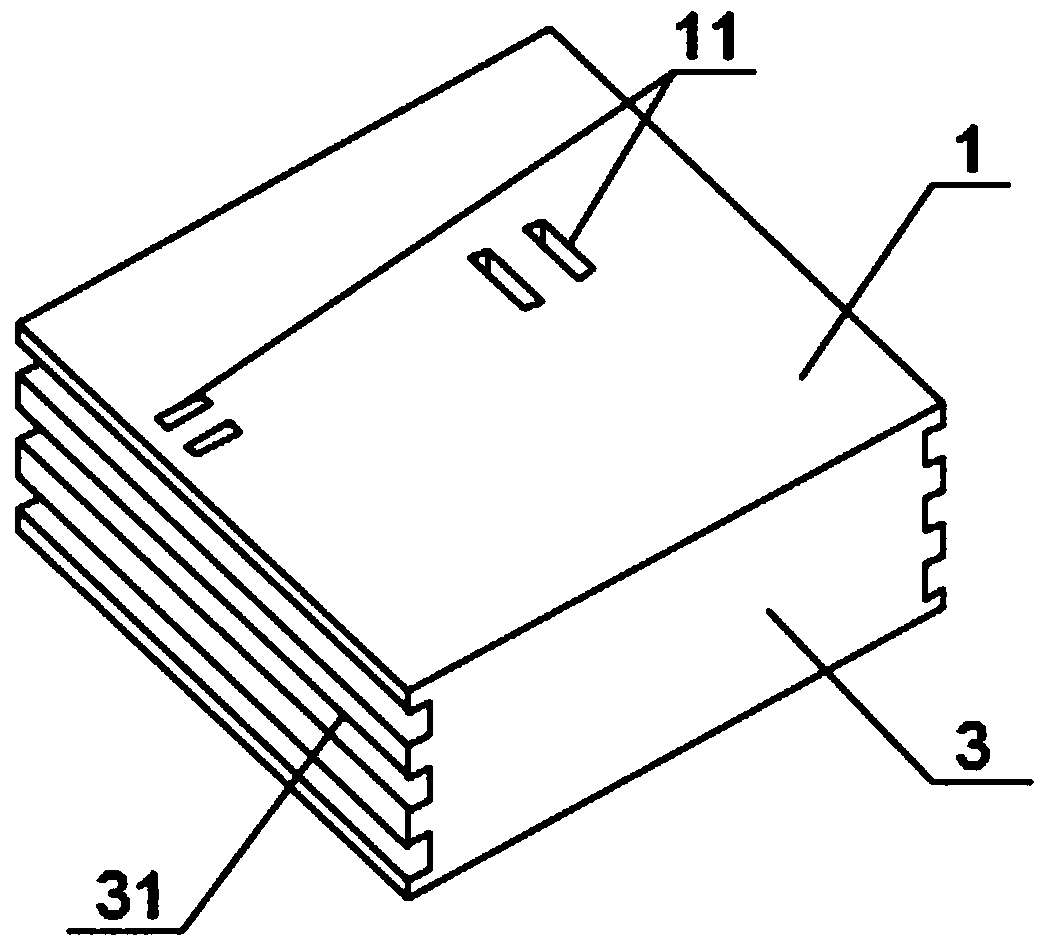

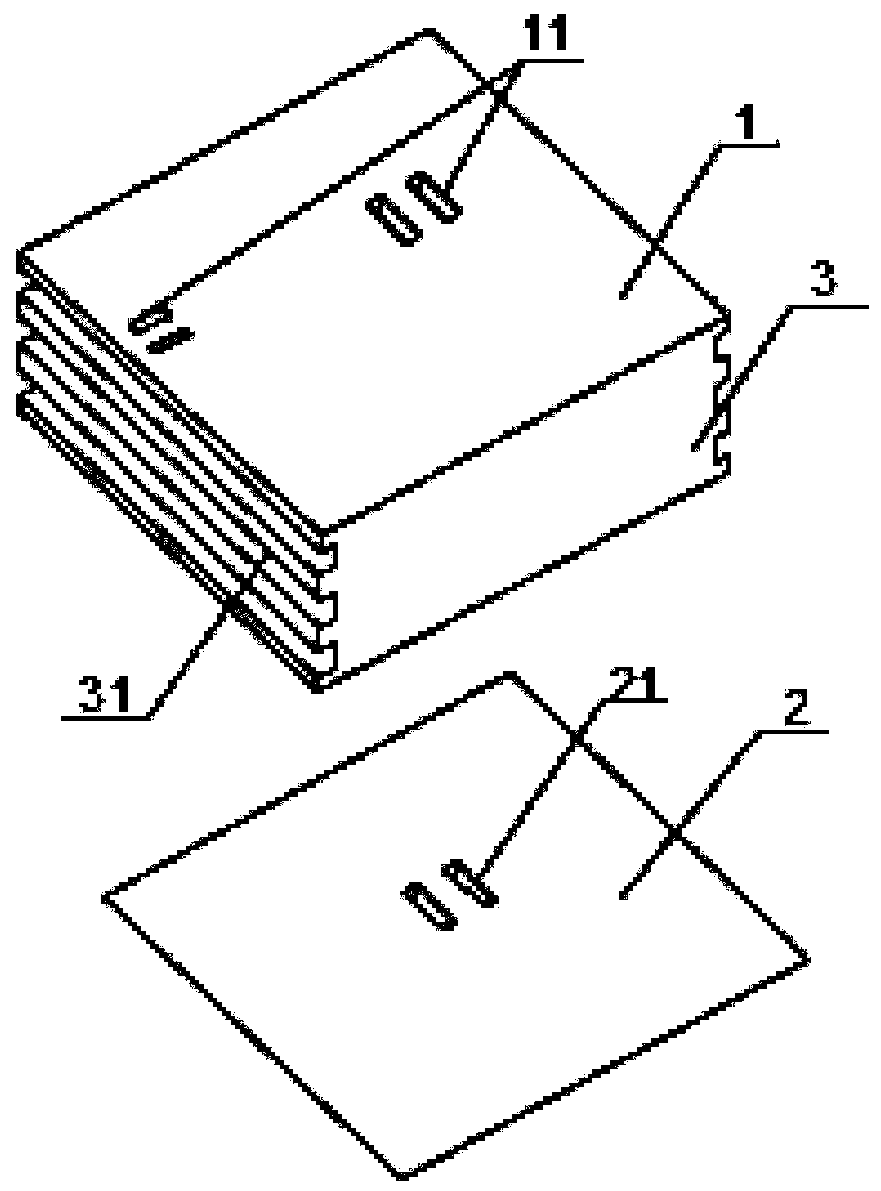

[0029] like figure 1 As shown, it is a schematic structural diagram of the anti-slip socket shell of the specific implementation case 1; figure 2 As shown, it is a schematic diagram of disassembly of the anti-slip socket housing of the specific implementation case 1. A hand-slip-resistant socket housing, comprising: an upper surface 1, a lower surface 2, and a side surface 3 for connecting the upper surface and the lower surface, and the lower surface 1 includes a jack 11 for passing through an electrode sheet, and its characteristics are: In that: the side surface 3 includes a non-slip surface 31 . When the upper surface 1 and the lower surface 2 are quadrilateral, the side surface 3 includes four planes, and the two opposite planes have anti-skid surfaces, so that the user can hold the two anti-skid surfaces by hand during the use of the socket. Face, force balance, and user experience favors increase. The side surface 3 is a flat surface, and the anti-skid surface 31 d...

specific Embodiment example 2

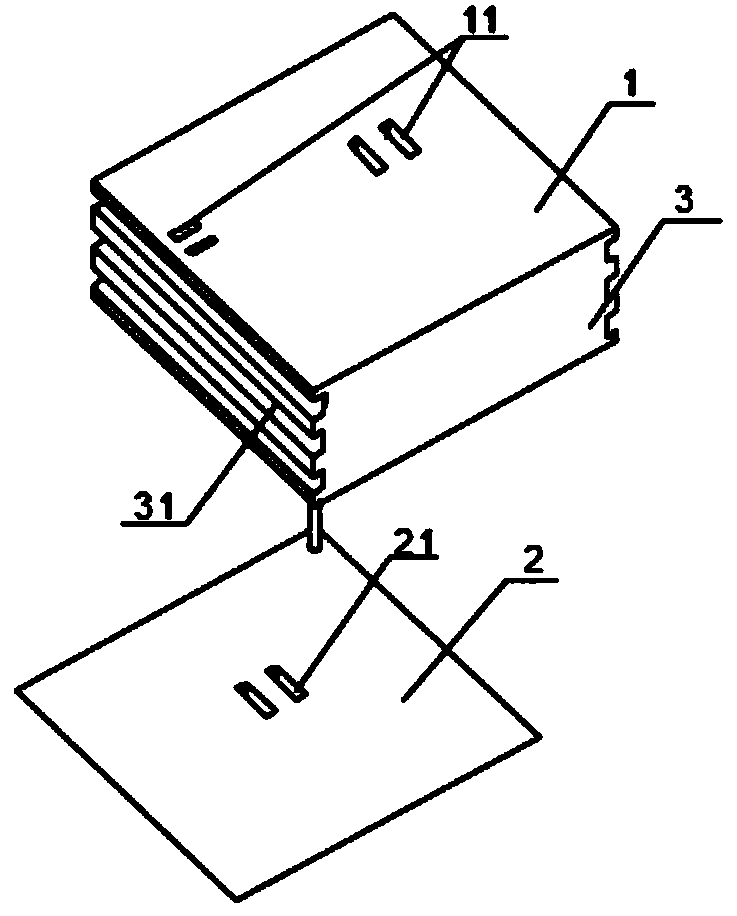

[0032] like image 3 As shown, it is a schematic diagram of the structure of the anti-slip socket shell of the specific implementation case 2; Figure 4 As shown, it is the front view of the anti-slip socket housing of the specific implementation cases 1 and 2; such as Figure 5-8 As shown, it is a side view when the non-slip surface of the anti-slip socket housing in the specific implementation cases 1 and 2 is a prism. A hand-slip-resistant socket housing, comprising: an upper surface 1, a lower surface 2, and a side surface 3 for connecting the upper surface and the lower surface, and the lower surface 1 includes a jack 11 for passing through an electrode sheet, and its characteristics are: In that: the side surface 3 includes a non-slip surface 31 . When the upper surface 1 and the lower surface 2 are quadrilateral, the side surface 3 includes four planes, and the two opposite planes have anti-skid surfaces, so that the user can hold the two anti-skid surfaces by hand du...

specific Embodiment example 3

[0034] like Figure 9 As shown, it is the front view of the side containing the anti-skid surface of the anti-slip socket shell of the specific implementation case 3; as Figure 10 Shown is a schematic diagram of the bumps on the anti-skid surface. The other structures in the specific implementation case 3 are the same as the specific implementation cases 1 and 2, except that the non-slip surface is replaced with the non-slip surface containing bumps, and the shape of the bumps is a triangular cone (or a triangular cone with a truncated tip). , hemispherical shapes, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com