Environment-adaptive cable channel and construction method thereof

A self-adaptive, cable trench technology, applied in the direction of cable installation, ground cable installation, cable laying equipment, etc., can solve problems affecting the performance of the sheath, and achieve the effect of avoiding aging and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

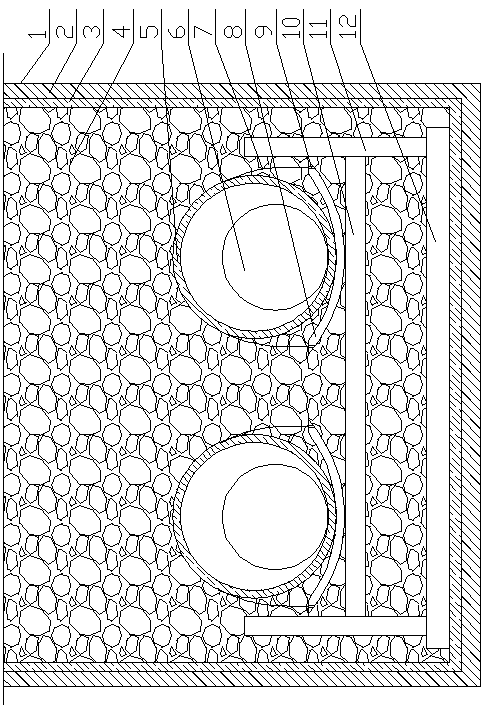

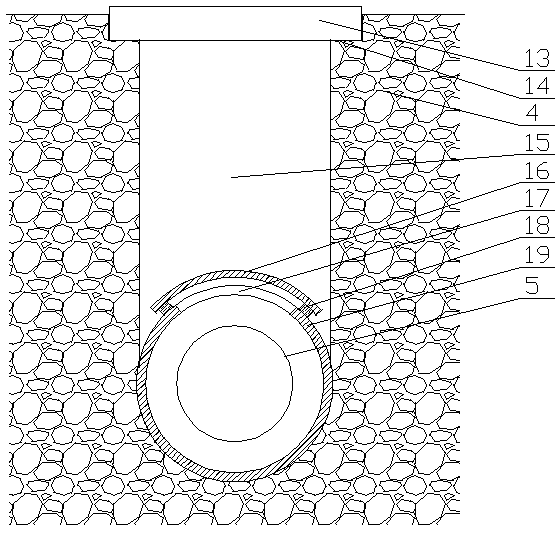

[0041] Embodiment 1, this embodiment provides an environment-adaptive cable trench, including a trench 1, a cement concrete layer 2 is provided on the bottom and sides of the trench 1, and a waterproof layer 3 is provided on the inner surface of the cement concrete layer 2, so that The bottom of the waterproof layer 3 is provided with a cable threading pipe 5 in the groove 1 through a support mechanism, and the outer side of the cable threading pipe 5 is provided with a thermal insulation filler 4 in the groove 1, and an overburden layer is arranged above the thermal insulation filler 4;

[0042] A heat dissipation mechanism is arranged in the cable passage 5, and the heat dissipation mechanism includes a cylindrical heat dissipation chamber 19 arranged on the cable passage 5, a CT energy-taking mechanism and a ventilation mechanism are arranged in the heat dissipation chamber 19, and the thermal insulation filler 4 Corresponding to the cooling cavity 19, an inspection channel ...

Embodiment 2

[0047] Embodiment two, its difference with embodiment one is:

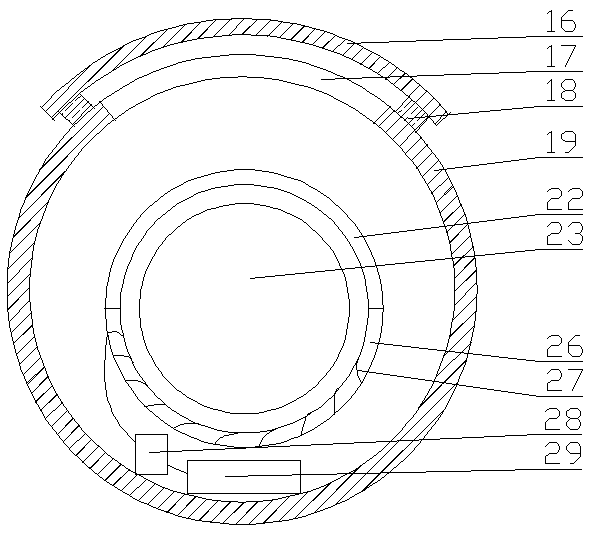

[0048] The diameter of the heat dissipation chamber 19 is larger than the diameter of the cable passage 5, and the heat dissipation chamber 19 is integrally formed with the cable passage 5. The upper part of the heat dissipation chamber 19 is provided with an inspection hole 17 and a seal is provided corresponding to the inspection hole 17. Cover plate 16, the sealing cover plate 16 is an arc surface structure fit with the cooling cavity 19, the area of the sealing cover plate 16 is larger than the area of the inspection hole 17, and the lower surface of the edge of the sealing cover plate 16 is provided with a sealing strip 18 , the sealing cover plate 16 is bolted to the cooling cavity 19 .

[0049] The CT energy-taking mechanism includes a first C-shaped iron core 26 and a second C-shaped iron core 22 sheathed on the cable 23, and the ends of the first C-shaped iron core 26 and the second C-shaped iron core...

Embodiment 3

[0051] Embodiment 3. This embodiment provides a construction method for an environment-adaptive cable trench, including the following steps:

[0052] S1. To excavate the trench, first complete the excavation of the trench as a whole, and then cast the cement concrete layer to support the bottom and side walls of the trench;

[0053] S2. Do a good job of waterproofing. After the cement concrete layer is solidified, apply asphalt to the surface;

[0054] S3. After the asphalt coating is dry, gradually set up the supporting mechanism in the trench and start fixing the cable through the pipe;

[0055] S4. Divide the cable conduits into several sections and erect them in turn. Each section contains two support mechanisms and cable conduits that need to be fixed on the two support mechanisms. Fix the cable conduits of the first section to the two supports of the first section. After the mechanism is installed, start to pour the foam concrete of the first section;

[0056] S5. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com