Full-automatic permanent magnetic telescopic device

A telescopic device, fully automatic technology, applied in the direction of electromechanical devices, electrical components, etc., can solve the problems of complex structure, large volume, large pollution, etc., and achieve the effect of wide application range and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

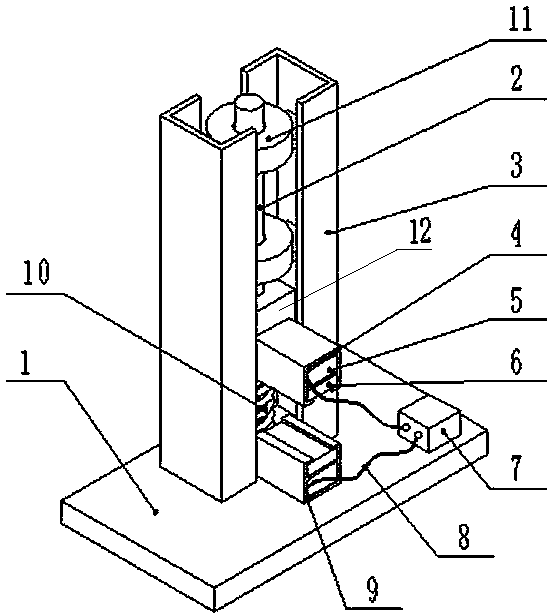

[0025] Fully automatic permanent magnet retractable device, such as figure 1 , 2 , 3, 7, and 8, the device includes a mechanical part, a permanent magnet part and a power supply, and the mechanical part includes a base plate 1, a slideway 3 fixed on the base plate and a spring 10 fixed on the base plate at the center of the slideway. The magnetic part includes two permanent magnet units. The permanent magnet unit includes a permanent magnet holder 9 made of non-magnetic material, a permanent magnet 6, an iron core 5 and a coil 4 wound outside the iron core. The coil is connected to the power supply through a connecting wire 8 7. The power supply is fixed on the bottom plate; the permanent magnet holder is a square box body, the two ends of the box body are not sealed, the upper end of the box body is open, the iron core and the permanent magnet are arranged on the permanent magnet holder up and down, and the permanent magnet set at the opening. The slideway is two symmetrica...

Embodiment 2

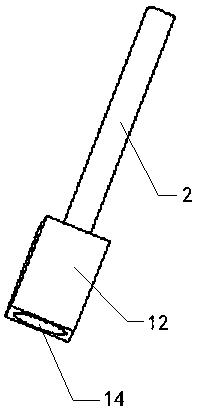

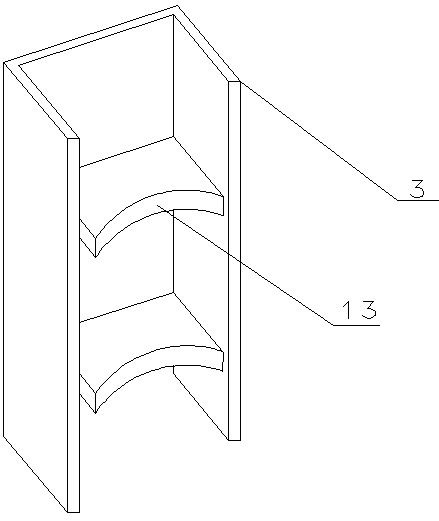

[0034] Fully automatic permanent magnet retractable device, such as Figure 4 , 5 , 6, and 7, the difference from the first embodiment is that the slideway 3 is two symmetrical semicircular tracks, the two sides of the slideway 15 are arc-shaped structures, and the parts of the arc-shaped structures on both sides of the slideway are connected with the semicircular tracks. The circular track matches, and the slide rail can slide up and down in the slideway. A circular hole 14 is provided at the lower end of the slide rail, and the free end of the spring 10 is fixed in the circular hole. One of the permanent magnet units is fixed on the bottom plate, the other permanent magnet unit is fixed on the front end surface of the slide rail, and the openings of the two permanent magnet units are opposite and arranged symmetrically. The working principle of this embodiment is exactly the same as that of Embodiment 1. The sliding rail moves up and down in the sliding rail under the acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com